High Quality Forged Steel Full Bore High Pressure Ball Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Forged Steel Full Bore High Pressure Ball Valve

Design Features Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Blow-out proof stem

Key lock

Anti-fire safe design

Anti-static device

Free leakage of body Sealed construction

Double block&bleed (DBB)

Emergency sealing

Automatic body cavity relief

Various driving types

Fire safe design to API 607/ API 6FA

Anti-static to BS 5351

Cavity pressure self relief

Optional locking device

Specifications of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Size: 1/4"-2"

Pressure: Class150LB-900LB

Material: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L,ASTM A351

Design & Manufacture Std.: API608, ASME B16.34

Connection Ends: Threaded (Female/Female), NPT, BSP, BSPT, DIN259/2999, Butt welded, Socket welded (BW, SW)

Test Standard: API598

Structure Type: One-piece, Two-piece, Three-piece, Reduced Bore

Operated way: Lever

Suitable medium: Water, oil, steam, nitric acid, acetate acid and so on

Suitable temperature: -40 deg+150deg be able to endure high pressure

Seat: PTFE. Material and good on-off feature.

Working pressure: 1000psi

Thread standard: International BSPT, NPT, DIN, surface is flat, allow overrun

|

Nominal pressure |

PN(mpa) |

2.5 |

4 |

6.4 |

|

|

Shell Test Pressure |

PS(mpa) |

3.75 |

6 |

9.6 |

|

|

Sealing test pressure |

2.75 |

4.4 |

7.04 |

| |

|

TightnessTest Pressure |

0.6 |

0.6 |

0.6 |

| |

|

For media |

SS201 |

SS304 |

SS316 |

| |

|

Water, oil and gas medium |

Nitric acid corrosive media |

Acetic acid corrosive medium |

| ||

|

For temperature |

-40°C——+150°C |

||||

|

Product Standards |

GB/T12237-2007 |

| |||

|

Test |

GB/T13927-1992 JB/T9092-1999 |

||||

Applicable Standard Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Design Standard: API 6D, ASME B16.34, API 608, BS 5351, MSS SP-72

Face to Face: API 6D, ASME B16.10, EN 558

End Connection: ASME B16.5, ASME B16.25

Inspection and Test: API 6D, API 598

Design Description Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Double block and bleed design(DBB)

Double stem sealing. The ball can maintain pressure sealing of pipeline when it is closed or fully opened.

Shorter upper sleeve reduces bearing load and operation torue

Limit device ensures the accurate opening and closing position of the valve

The vall and stem are separated so as to reduce stem load. The stem adopts anti-blow-out design.

The sealing surface is inserted into te metal seat by polymer or plastic

The metalbacked self-lubricating PTFE bearing and PTFE thrust washers

Reduce the opening torque and prolong the service life of the valve. Stem leakage can be prevented through the emergency grease fitting.

Nickel and phosphor treatment to the parts can enhance the anticorrosive performance.

The fireproof design of metal wound gasket compassed of stainless steel and graphite can prevent external leakage.

Usage/Applications Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

It can be widely used in Metallurgy, Mine, Petrochemical, Chemical, Oil & Gas transmission pipeline, Power plant, Heating power and Pharmacy, etc.

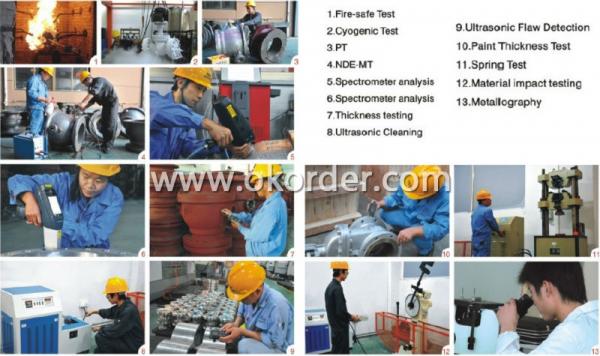

Main Test Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging & Delivery Of High Quality Forged Steel Full Bore High Pressure Ball Valve:

Packaging: Inner packing: Plastic bags, Outer packing: Cartons and wooden case.

- Q: What is the difference between floating and fixed ball valves?

- Fixed ball valve is the ball with the lower stem fixed, pressure will not produce movement, therefore, in the design, two sealing ring must have sufficient preload to ensure that the valve seat and sphere seal, is a two sided forced seal. Thrust or sliding bearings are usually provided on the upper and lower stems of the ball.

- Q: What's the diameter of the 4 point ball valve?

- 4 points is 0.4 inches, 1 inches =25.4 mm.Then the 4 point ball valve diameter is 10.16mm.

- Q: How does ball valve indicate?

- Valve type designation method is standard, the landlord himself to check the JB/T308 standard, Baidu library some, and is free to download:JB/T 308-2004 valve type method of preparation clear Edition

- Q: Which is more cost-effective electric ball valve?

- All kinds of Lady valve manufacturers.The company has strong technical force, with adequate and sophisticated machining equipment as the premise, to provide a strong guarantee for the production of high-quality products,

- Q: You can connect inside the pump and valve

- Pump and valve should be installed between the distance, too close, too far, will cause damage to the ball valve. The flange is usually used on the pump. Valve can be connected with a pipe with screw pipe, a head welding flange, and the flange is directly connected with the water pump. Super - Electronic Commerce

- Q: Three electric ball valve type T and type L what is the difference?

- Electric three way ball valve is a kind of valve, can be divided into L and T type.The T type can cause three orthogonal pipes to connect with each other and cut off third channels, thus diverting and merging the channels.Two pipeline L three ball type valve can only be connected mutually orthogonal, communicating with each other while maintaining the third pipeline, only as a distribution function.Type T and L type reversing diagrams are as follows:Turn left and turn right |

- Q: Into the tap valve, with globe valve or ball valve?

- Water valve at home as far as possible not to use the form of valve, gate valve for water, slag better, shut down with the next valve and ball valve.

- Q: Daily maintenance of ball valve

- The new parts need to be cleaned before assemblingThe assembly should have metal fragments, fiber, fat is not allowed (except the requirement to use) dust and other impurities, foreign matter contamination, adhesion or remain in part into the cavity on the surface or, if the packing is micro discharge, to lock the stem nut.Note: do not lock too tight, usually lock 1/4 circle to 1 laps, the leak will stop.(A) disassemblyMake the valve in a half open position, flush and remove dangerous substances that may exist inside and outside the valve body.Close the ball valve, remove the connecting bolts and nuts on both sides of the flange, and then remove the valve completely from the line.In order to remove the drive - actuator, a connecting bracket, lock washer, stem nut, butterfly spring, glam, wear plates, valve stem packing.Remove the body cap connecting bolts and nuts, separate the valve cover from the valve body and take off the valve cover washer.Make sure the ball is in the "off" position, which can be easily removed from the valve body and then removed from the valve seat.A hole in the body downward nudge stem until completely removed, and then remove the packing ring and the O.Caution: Please operate carefully to avoid galling, stem surfaces and body packing box seals.B) reassembleCleaning and inspection of the parts removed, it is strongly recommended to use spare parts package replacement valve seat and valve cover, gaskets and other seals.Assemble in reverse order of disassembly.Cross the locking flange bolts with the specified torque.Lock the stem nut with the specified torque.

- Q: What's the difference between a hot melt ball valve and a ball valve in general? What's the use of it?

- Ball valve (in the field of marine engineering and ships should be cut-off valve), standard GB/T21465-2008 "valve terminology" is defined as: "open and close parts (spheres) driven by the stem, and around the axis of the ball valve to rotate the valve movement.". Can also be used to regulate and control fluid, strong shear force between the metal seat seal V type ball valve V type ball core and welding hard alloy, especially suitable for containing fibers, small solid particles and other media. Switch and multi way valve in the pipeline not only can flow, and flow diversion, flexible control of the medium, but also to turn off any channel to the other two channels. This kind of valve should be installed horizontally in the pipeline. In accordance with the way to drive the ball valve is divided into: pneumatic ball valve, electric ball valve, manual ball valve.Ball valve was introduced in 1950s, with the rapid development of science and technology, production process and product structure of continuous improvement, in a short span of 40 years, has rapidly developed into a major valve category. In western developed countries, the use of ball valves is increasing year by year.

- Q: Domestic water pipe ball valve or cut-off valve?

- Ball valve: rotate 90 degrees to switch, but the performance of the valve relative to the cut-off valve.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; MidEast; Africa; Oceania; East Asia; Europe; Japan; Southeast Asia |

| Company Certifications | ISO 9001:2008; CE; API-6D |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Forged Steel Full Bore High Pressure Ball Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords