High-Quality Affordable Aluminum Angle Strips for Aluminum Composite Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

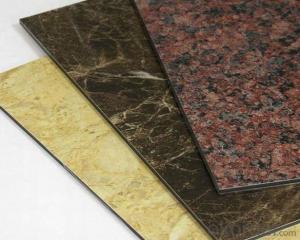

Aluminum composite panel

3005-H15 0.35mm*680mm ID:508mm

Application:

1, building external wall, curtain wall plate.

2, the old building exterior wall modification and retrofit.

Unit 3, balcony, equipment, interior compartments.

4, panels, logo plate, display platform.

5, the interior wall decoration panel, ceiling, advertising signs.

6, industrial materials, cold car body.

7, air conditioning, TV and other electrical appliances shell.Layer or acrylic coating

The upper and lower the minimum thickness of aluminum plate is not less than 0.50 mm, total thickness shall be not less than 4 mm.Aluminum material shall comply with the requirements of GB/T 3880, typically use the series of aluminum alloy plate, such as 3000, 5000, coating fluorocarbon resin coating should be adopted.

B. exterior wall decoration and advertising with aluminous model board

T-shirt bag | Width | 200-400mm |

Length | 300-600mm | |

Thickness of film | 0.01-0.05mm | |

Speed | 250-300pcs/min | |

Machine | Weight | 2600kg |

Power | 12.5kw | |

Air compression | 10hp | |

Dimensions | 7000x1600x1800mm |

PE primary use is in packaging (plastic bag,plastic films, geomembranes, containers including bottles, etc.). Many kinds of polyethylene are known, with most having the chemical formula.

.

- Q: This question asks about the strength or durability of aluminum strips, which are commonly used in various industries.

- <p>Aluminum strips are known for their strength-to-weight ratio, offering a high level of strength relative to their weight. They can withstand significant tensile loads and are highly resistant to corrosion. The exact strength of an aluminum strip depends on its alloy composition, thickness, and temper. For instance, 6061-T6 aluminum, a common alloy, has a yield strength of approximately 276 MPa (40,000 psi) and a tensile strength of around 310 MPa (45,000 psi). Aluminum strips are also ductile, allowing them to be bent and shaped without breaking. Their strength makes them suitable for applications in construction, transportation, and aerospace industries.</p>

- Q: Is it possible to use aluminum strips as a material for wall cladding?

- <p>Yes, aluminum strips can be used for wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for both interior and exterior applications. Aluminum strips are also easy to install and maintain, and they can be painted or finished in various ways to match different architectural styles. However, it's important to ensure that the aluminum is of high quality and that the installation is done correctly to achieve a secure and aesthetically pleasing result.</p>

- Q: Explain the differences between aluminum strips and aluminum foil.

- <p>Aluminum strips and aluminum foil, while both made of aluminum, differ in their form and usage. Aluminum strips are typically long, narrow pieces of aluminum, often used for structural purposes or as a component in various applications due to their strength and flexibility. They can be found in various thicknesses and widths, suitable for industrial and construction uses. Aluminum foil, on the other hand, is a thin, pliable sheet of aluminum, commonly used in cooking, food packaging, and insulation. It is much thinner than aluminum strips and is known for its high malleability and heat resistance, making it ideal for wrapping food and baking.</p>

- Q: This question asks for an explanation of the various kinds of aluminum strips that exist, which could include their properties, uses, and any other distinguishing features.

- <p>Aluminum strips come in various types, differentiated by their alloy composition, thickness, width, and temper. Common types include 1000 series strips, which are 99% pure aluminum, known for their high thermal and electrical conductivity. 3000 series strips, like 3003 alloy, offer good formability and are used in cooking utensils and chemical equipment. 5000 series strips, such as 5052, are known for their strength and are used in marine applications and aircraft structures. 6000 series strips, like 6061, are heat-treatable and used in construction and automotive parts. Each type has specific properties that make them suitable for different applications, from lightweight structures to high-strength components.</p>

- Q: This question asks for a comparison between standard aluminum strips and custom-made aluminum strips, highlighting their differences.

- <p>Standard aluminum strips are mass-produced with fixed dimensions and specifications, making them readily available and generally more affordable. They are suitable for common applications where specific requirements are not needed. On the other hand, custom-made aluminum strips are manufactured according to specific customer requirements, including size, shape, thickness, and alloy type. This customization allows for unique applications and better performance in specialized environments but may come at a higher cost and with longer lead times due to the bespoke manufacturing process.</p>

- Q: What characteristics of aluminum strips make them an ideal material for roofing purposes?

- <p>Aluminum strips are suitable for roofing due to their lightweight nature, which reduces structural load. They offer excellent corrosion resistance, protecting against rust and decay, and are highly durable, maintaining their integrity for decades. Aluminum's malleability allows for easy shaping into various profiles, enhancing design flexibility. Additionally, aluminum strips reflect heat well, reducing energy consumption for cooling, and they are recyclable, contributing to environmental sustainability.</p>

- Q: Is it possible to recycle aluminum strips?

- <p>Yes, aluminum strips can be recycled. Recycling aluminum is a highly efficient process that conserves resources and energy. Aluminum is infinitely recyclable without losing its properties, making it an environmentally friendly choice. The recycling process involves melting the aluminum, which requires significantly less energy compared to producing aluminum from raw materials. This not only reduces waste but also lowers greenhouse gas emissions. Proper recycling of aluminum strips helps in conserving natural resources and reducing the environmental impact of aluminum production.</p>

- Q: What are the certifications or standards that apply to aluminum strips?

- <p>Yes, there are several certifications and standards for aluminum strips. These include ASTM B209, which specifies requirements for aluminum and aluminum alloy sheet and plate, and EN 573, which covers the chemical composition and mechanical properties of aluminum and aluminum alloys. Additionally, there are ISO standards such as ISO 6361 and ISO 6892 that define the requirements for aluminum and aluminum alloys in terms of mechanical properties and chemical composition. These standards ensure the quality and consistency of aluminum strips used in various industries.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof or wall.

- <p>To install aluminum strips on a roof or wall, follow these steps: 1. Measure and mark the area where the strips will be installed. 2. Clean the surface thoroughly to ensure proper adhesion. 3. Cut the aluminum strips to the required length using a hacksaw or tin snips. 4. Apply a bead of construction adhesive along the top edge of the strip. 5. Press the strip firmly into place, starting from one end and working your way along the surface. 6. Use a level to ensure the strip is straight and secure it with nails or screws at regular intervals. 7. Fill any gaps between the strips and the surface with caulk to create a watertight seal. 8. Finish with a coat of paint or sealant to match the surrounding area and protect the aluminum from weathering. Always follow the manufacturer's instructions for the specific adhesive and sealant products you are using.</p>

- Q: The user is asking if it's possible to use aluminum strips for constructing carports or garages.

- <p>Yes, aluminum strips can be used for carports or garages. They are lightweight, durable, and resistant to corrosion, making them a popular choice for outdoor structures. However, it's important to ensure that the aluminum is of sufficient gauge to support the weight and withstand environmental conditions. Additionally, proper design and engineering are crucial to ensure the structure's stability and longevity. Always consult with a professional to determine the best materials and construction methods for your specific needs.</p>

Send your message to us

High-Quality Affordable Aluminum Angle Strips for Aluminum Composite Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords