Marble Aluminum Composite Panels with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 350000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

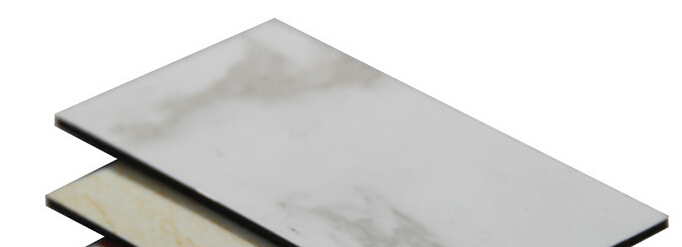

1. Structure of Marble Aluminum Composite Panels Description:

Marble Aluminum Composite Panels is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

Marble finish Aluminium Composite Panel (ACP) or Aluminium Composite Material (ACM) is a widely-used term describing flat panels that consist of a non-aluminium core bonded between two aluminium sheets. Aluminium sheets can be coated with PVDF or Polyester paint. ACPs are frequently used for external cladding of buildings (building facades), for insulation and for signage.

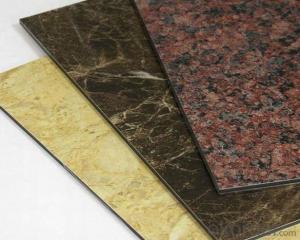

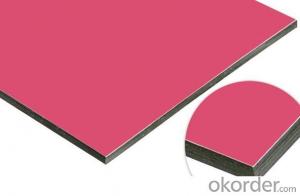

2.Main Features of the Marble Aluminum Composite Panels:

Super peeling strength

Excellent surface flatness and smoothness

Superior weather, corrosion, pollutant resistance

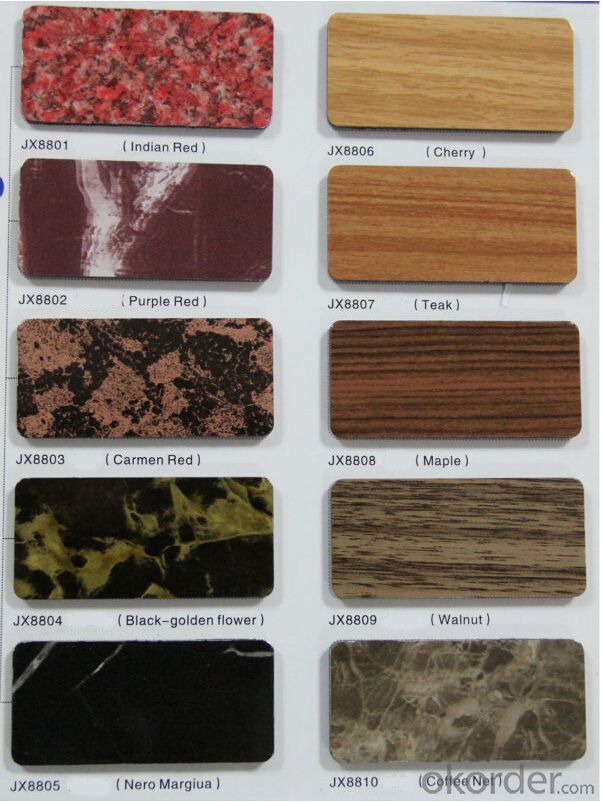

Even coating, various colors

Fireproof, excellent heat and sound insulation

Superior impact resistance

Lightweight and easy to process

Easy to maintain

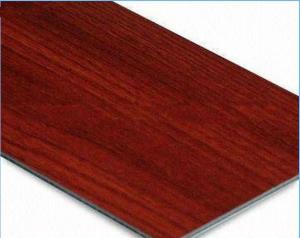

3. Marble Aluminum Composite Panels Images

4. Marble Aluminum Composite Panels Specification

Standard size | 1220*2440*3mm and 1220*2440*4mm |

Width | Max:1550mm |

Length | Max:6000mm |

Thickness | 2mm,3mm,4mm,5mm |

Aluminum sheet tickness | 0.15mm~0.5mm |

Weight | 5.5kg/m2 base on 1220*2440*4mm |

Nonstandard | sizes are available according to your requirement |

Standard size | 1220*2440*3mm and 1220*2440*4mm |

Width | Max:1550mm |

Length | Max:6000mm |

5.FAQ

① Are you a trade or manufacturer.

We are a professional manufacturer. Welocme to visit our company.

②What is the scope?

Curtain wall of buildings/ Roof & house eave/ Wall board, movable house/ Display trestle/

Vehicle wagon,yacht interior & exterior/Old building exterior wall face-lifting/ Balcony,

comportment/ Door decoration/ Signboard, advertisement board/ Machine, apparatus casing.

③How about the quality?

we can return the value of the problem goods,if it is our quality factor.

- Q: What is the material of the polymer film of aluminum-plastic plate?

- The role of the equivalent of double-sided paste, one side of the bonding aluminum plate, one side of the extruded core plate.

- Q: What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- The production process of aluminum plate is hot rolling, casting rolling, casting, etc., in which the aluminum plate made by hot rolling is superior to the aluminum produced by other processes in the aspects of stretching, oxidation and so on.With the cost of hot plate Production costs are relatively high.

- Q: Aluminum-plastic plate and color steel tile which is more durable

- Aluminum-plastic panels are more durable.

- Q: Do you want to install aluminum alloy doors and windows on the external wall?

- You want to open a single door and window, you can press a full protection King Kong screen window

- Q: What are the folds of aluminum

- Aluminum-plastic composite board slot can generally open V-groove, U-slot, etc., several typical slotted as shown in Figure 1. Aluminum-plastic composite panel plate in the cutting board to take into account the size of the fold , Generally add about 25mm on each side. Cut the composite board needs four sides of the planing slot, that is cut to a certain width of the inner layer of aluminum and plastic layer, slot depth must be strictly controlled in the front aluminum plate at least 0.3mm thick plastic core To ensure that the aluminum-plastic composite panels have sufficient toughness to prevent the fold at the aluminum skin fracture, and then folded into a 90 ° angle, so the board surface weight and curtain wall at any time will be positive and negative wind load pressure by the four sides 0.5mm aluminum plate to bear, therefore, slotting is the aluminum-plastic composite panel panel of the weakest link, but also under the wind load under the first destruction of the site

- Q: Aluminum plate is a plastic plate or metal plate

- Strictly speaking, aluminum-plastic panels and aluminum veneer are a kind of metal curtain wall material

- Q: Does the aluminum plate itself fire? Not aluminum plate

- More than their own melting point. It will not fire

- Q: What is the chemical chemistry of the synthetic plastic of the aluminum-plastic plate?

- The specific operation is: the aluminum plate into the pot, and then add caustic soda, the water burned to about 60 ℃, to separate the aluminum-plastic plate, the aluminum plate separated into aluminum and plastic plate. This kind of plastic can be recycled into black particles

- Q: My family in Foshan Chancheng, home kitchen ceiling to change! Do not know the aluminum plate is good, or aluminum-plastic plate is good? How much are their prices and materials?

- Personal personal advice you do aluminum plate, because the aluminum plate is to use glue attached to the plywood, which is related to the quality of the glue, followed by the paste technology is also related to the three also with the splint of the ups and downs, and finally Ask you still ready to replace it? If sure, that aluminum plate will not bring you trouble, if not change, it is still aluminum plate, the time is better. The price of a business can be imagined

- Q: What is the size of the general aluminum-plastic board?

- 1M * 2M

Send your message to us

Marble Aluminum Composite Panels with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 350000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords