High Purity Calcined Bauxite Powder - Raw Materials for Refractory by CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

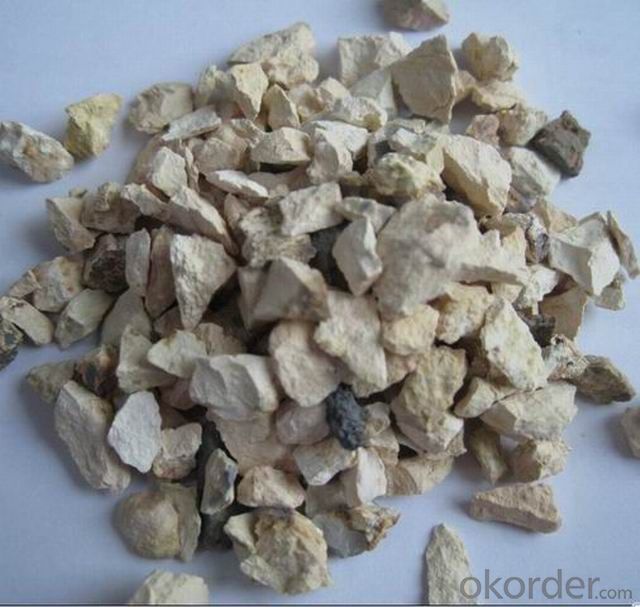

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns.

Applications

calcined bauxite is typically calssified according to its intended commercial application,such as abrasive ,cement ,chemical, metallurgical, and refractory .as raw material for use in high alumina and super duty refratory bricks and shapes ,plastics ,castable refratory, motors, gun mixes, ramming mixes, abrasive grains and other products

Chemical Specification:

Rotary Kiln Calcined Bauxite

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.30 |

- Q: Where is the production of refractory manganese alloy manufacturers? Manganese is recommended between 63 and 70!

- There are a lot of silicon manganese alloy manufacturers, production market is relatively large, the manganese content in manganese alloys between 63 to 70 or more common

- Q: Can someone professionally introduce the classifications of refractories?

- It can be divided into two categories of ordinary and special refractory. Ordinary refractories can be devided into acidic, neutral and alkalinee refractories according to chemical properties. Special refractory can be devided into high temperature oxide, refractory compounds and high-temperature composite materials according to the compositions. Furthermore, it canbe devided into ordinary refractory products (1580 ~ 1770 ℃), advanced refractory products (1770 ~ 2000 ℃) and super refractory products (above 2000 ℃) according to the strength of refractoriness. It can be divided into bulks (standard brick, special-shaped brick, etc.), special shape (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia and boron carbide, etc.) and Indefinite shape (refractory clay, castableand ramming mass, etc.) according to the shapes of products. According to the sintering process, it can be divided into sintered products, cast products, melting jetting products.

- Q: who knows the fire resistant levels of fireproofing glass?

- According to the fire resistance levels, it can be divided into three categories: Class A: a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Including composite flameproof?glass and perfusion type fireproofing glass . This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B: Marine fireproofing glass, including porthole fireproofing glass and rectangular window fireproofing glass, surface glass pane is tempered safety glass, the inner surface glass pane material can be arbitrary selection. Class C: it's a kind of monolithic fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements.

- Q: Which industry does the metallurgy and thermal insulating and refractory material belong to?

- Materials Industry

- Q: What are the features of construction class A fire resistant door ?

- 1, fireproof and thermal insulation Foam cement board is a Class A non-combustible inorganic heat preservation material which has good fireproof?performance can remain integrity after 3 hours baking at 1200℃. It can be used in buildings to improve fireproof?performance.

- Q: What is the concept of lightweight refractory material?

- Lightweight refractory material has high porosity, mechanical strength and erosion resistance. Compared with normal refractory bricks, it is a kind of refractory material with large volume shrinkage in high temperature, low thermal conductivity and small bulk density. It is used as thermal insulation material in industrial furnace and other thermal equipments. It has poor wear resistancel.

- Q: How is refractory material made?

- It is made from yellow mud and water.

- Q: Who knows the external wall thermal insulation materials fire rating requirements?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q: Which brand of refractory fiber hard thermal insulation board is better?

- Luyang ceramic fiber semi-hard board is good for it has typically applied major technological performance industrial furnaces backing, wall lining, lining material, electric heating furnace backing lining heat insulation ceramics shuttle kiln, backing lining of tunnel kilnand roller kiln.

- Q: What are the fireproofing materials of the external wall included?

- According to the external wall thermal insulation materials, the external insulation materials is in general divided into Class A and Class B. The A class is non-combustible material. The B class is combustible materials. The fire disasters of the CCTV building and Shenyang hotel are both caused by the B level materials. Generally, the A level material will be used, and some prices are even cheaper than the B-grade material. A level is roughly divided into thermal?mortar, phenolic foam Board, rock wool board, foam cement board, and so on. I hope my answer will help you!

Send your message to us

High Purity Calcined Bauxite Powder - Raw Materials for Refractory by CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords