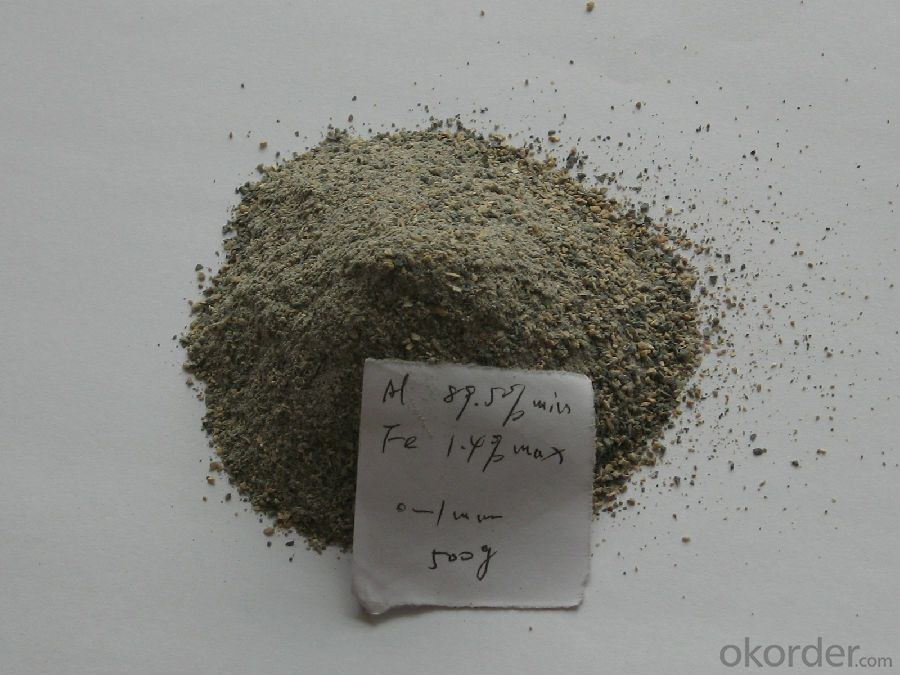

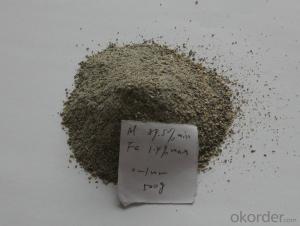

High Purity Calcined Bauxite Powder - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Castable |

| SiO2 Content (%): | 0.5-15 | Al2O3 Content (%): | 55-95 | MgO Content (%): | 0.3 |

| CaO Content (%): | 0.3 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | Customer's Requirement | Brand Name: | cnbm |

Packaging & Delivery

| 1. 25KG or 50KG bag inside, jumbo bag outside or pallet 2. Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. | |

| Delivery Detail: | Within 20 days |

bauxite refractory powder

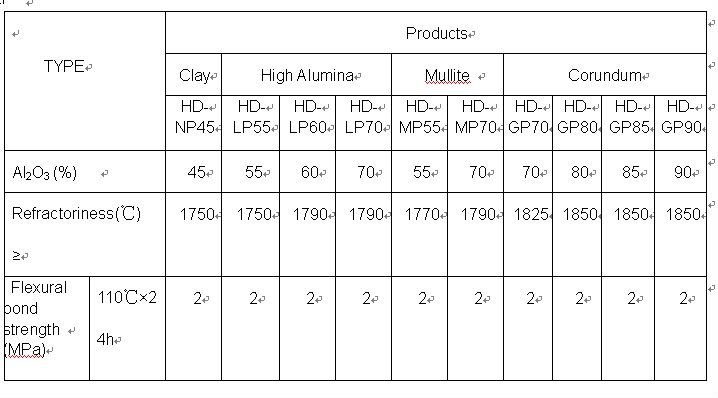

To meet the big size rotary kiln requirements, after long time research on rotary kiln refractory wearing and damage mechanism, Hongda company developed HD series rotary kiln refractory products, with advantages of good thermal stability, excellent resistance to abrasion and erosion, as well as long work life, insure the long time stable production of rotary kiln, create remarkable social and economic effects.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: A chemical problem with refractory materials

- In chemistry, there is never absolute

- Q: What are the requirements of refractory temperature of refractory brick?

- Refractory bricks furnace pipe material is generally divided into two types, namely, shapeless refractory material and shaped refractory. Shapeless refractory material, also known as castable refractory, is hybrid powder material made up of many kinds of aggregate or aggregate and a kind of or many kinds of binders. It must cooperate and evenly stir with a kind or many kinds of liquids during use and has strong mobility. Shaped refractory material usually refers to refractory brick whose shape has standard rules. It can also be processed temporarily during cutting according to requirement. Refractory brick, called refractory brick for short, is refractory material made by firing refractory clay or other refractory raw materials. Faint yellow or brownish, it is mainly used in building smelting furnace. It can resist 1,580 ℃-1,770 ℃ high temperature.

- Q: Where is refractory used? Thank you!

- Currently, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, ceramics and other industries. The current definition of refractory does not only depend on whether the refractoriness is above 1,580℃.

- Q: I am a manufacturer of refractory materials. I would like to receive some orders from abroad. I would like to know what foreign trade companies in Dalian place foreign orders abroad

- Dalian foreign trade companies are numerous, and fire prevention materials are also quite a lot

- Q: Does the refractory material used in steelmaking all refer to refractory brick?

- Besides refractory brick, it also refers to unshaped refractories like fire clay and castables.

- Q: How to apply the alumina powder on refractories?

- The most common one in use is the refractory bricks.

- Q: How many fire endurance grades are the AAA fire resisting shutter divided?

- The different fire resistant levels of the building have different requirements of the fire endurance of the building component. According to the fire endurance, the fire doors can be divided into Class A, Class B and Class C fire doors with the fire resistances are not less than 1.20h, 0.90h and 0.60h. Even the fire resistant level of B can also use the first rate fire resistant door.

- Q: What is the main material of fireproof wooden door?

- Fireproof wooden door refers to the door whose fire endurance of door frames, skeleton of the door leaf, door panels made of timber or timber work reaches the provisions of "GB50045-95 design of tall buildings for fire protection". Fireproof wooden door contain retardant timner, fireproof expanded perlite and fireproof?panel. Accessories: fireproof glue, fireproof hardware.

- Q: What is neutral refractory? Can refractory suppliers tell the main components of it?

- The material using Al2O3, clay, bauxite and corundum as the main components is neutral material; the material using MgO and CaO as the main components is basic material; the material using SiO2 as th emain component is acidic material.

- Q: Who knows about the B-level fireproof insulation materials?

- Organics, extruded sheet, polyphenyl board and phenolic resin. The fireproof?performance of sea capacity module (fireproof and thermal insulation material) is B1-level with the heat conductivity coefficient of only 0.028w / m · k. It is a good choice. A-level: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic aldehyde, and foam glass. B-level: Rubber and plastic, extrusion molding, polyphenyl, PEF.

Send your message to us

High Purity Calcined Bauxite Powder - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords