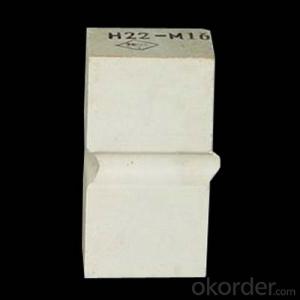

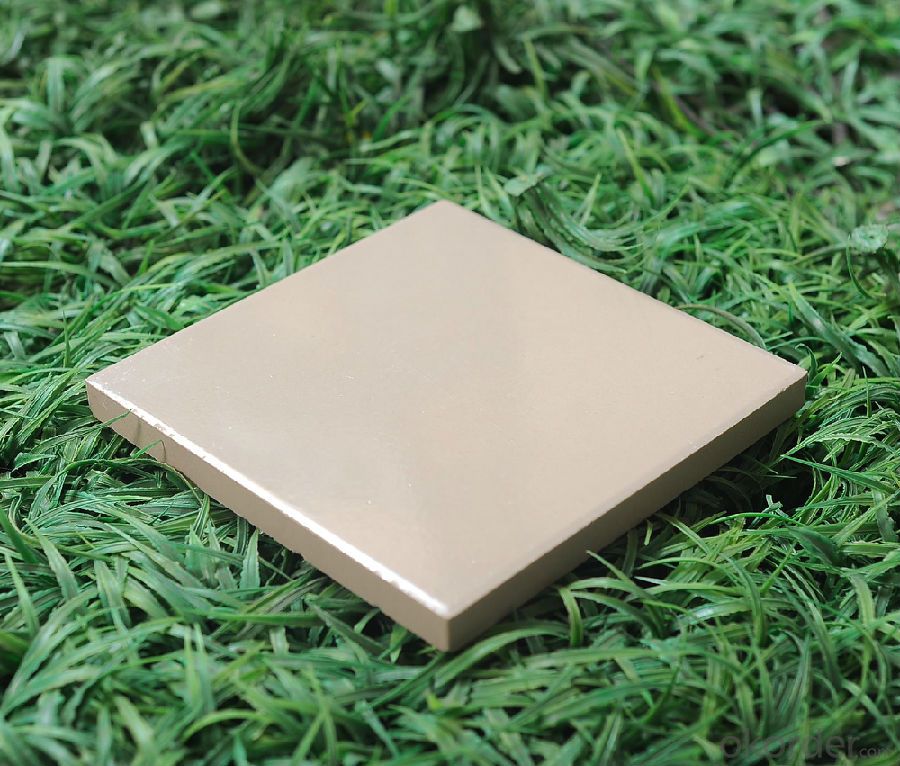

High Purity Acid Resistant Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Type: | Ceramic Plates | Application: | Ceramic Decorations |

| Material: | Alumina Ceramic | Model Number: | TW92 | Brand Name: | Tecera |

| Alumina Content (%): | ≥92 | Moh's Hardness (Mohs): | 9 | Rate of Water Absorption(%): | ≤0.01 |

| Fracture Toughness(n/mm): | 40 | Bending Strength (Mpa): | 255 | Bulk Density (g/cm3): | ≥3.63 |

Packaging & Delivery

| Packaging Details: | In carton box or PP-bag , packed in fumigated wooden pallet with net weight 20 - 25MT/20'FCL |

| Delivery Detail: | 30 days |

TW Series ® -Alumina Wear Resistant Ceramics Tile

An ISO9001&ISO14001 Certificated Company

Application:

The products, which are of wear-resistance, excellent impact-resistance, easy operation are ideal surface wear-resisting material for material transfer equipment in mining, iron & steel works, thermal & power plants, mine, etc, and can extend operating life of equipment effectively. Theoretically the life time of the alumina ceramic is about 260 times longer than that of manganese steel and 170 times longer than that of chrome steel.

Performance Index:

Products | TW92 ® | TW95 ® | TW97 ® | TW99® |

Alumina Content (%) | ≥92 | ≥95 | ≥97 | ≥99 |

Moh’s Hardness (Mohs) | 9 | 9 | 9 | 9 |

Rate of Water Absorption(%) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Fracture Toughness(n/mm) | 40 | 42 | 44 | 48 |

Bending Strength (Mpa) | 255 | 275 | 285 | 300 |

Bulk Density (g/cm3) | ≥3.63 | ≥3.68 | ≥3.73 | ≥3.83 |

Specifications:

Size(mm) | Length(mm) | Width(mm) | Thickness (mm) | Shape |

10X10 10*10 lining Facing | 10 | 10 | 1.5-10 | Mosaic/Hex.Tile |

11.55X11.55 | 11.55 | 11.55 | 3-12 | Mosaic/Hex.Tile |

12X12 | 12 | 12 | 3-12.7 | Mosaic/Hex.Tile |

17.5X17.5 | 17.5 | 17.5 | 4-10 | Mosaic/Hex.Tile

|

20X20 | 20 | 20 | 5-15 | Mosaic/Hex.Tile

|

23.7 x23.7 | 23.7 | 23.7 | 5-15 | Mosaic/Hex.Tile

|

25X25 | 25 | 25 | 5-15 | Mosaic/Hex.Tile

|

50X25 | 50 | 25 | 5-10 | Plain Tile(Without Hole) |

50X50 | 50 | 50 | 5-15 | Plain Tile(Without Hole) |

100X100 | 100 | 100 | 6.5-15 | Plain Tile(Without Hole) |

120X80 | 120 | 80 | 6-20 | Weldable Tile (With Hole) |

150X60 | 150 | 60 | 10-25 | Plain Tile(Without Hole) |

150X100 | 150 | 100 | 6-25 | Plain Tile(Without Hole) |

150X100 | 150 | 100 | 12-50 | Weldable Tile (With Hole) |

Remark: More than 2000 sizes and shapes are available upon customer requests.

Packaging: In carton box or PP-bag , packed in fumigated wooden pallet with net weight 20-25MT/20'FCL.

Key benefits:

·Excellent anti-wear and corrosion resistance.

·Longer life than that of traditional wear protection material. ·Avoid shutdown time and maximize the productivity of your plant.

- Q: How to clean the acid brick surface dirt?

- Daily cleaning of bricks can be done with detergent, soap and other cleaning.

- Q: What are the standard specifications for acid resisting bricks?

- First: according to the environment to determine the acid resistant brick specifications.Second: inspects the good acid resisting brick performance.

- Q: What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q: Is acid proof brick alkali resistant?

- Acid resistant brick is generally acidic or neutral, it itself will not react with acidic materials, but neutral materials can be divided into neutral partial acid, neutral partial alkali and absolutely neutral (such as silicon carbide, etc.).

- Q: How can acid proof cement be used?

- Acid resistant cement should be hardened at temperatures above 15 degrees Celsius, and maintained in the air for about 10-20 days, the winter temperature is low, time is long, as far as possible not suitable for use.

- Q: Consult: water treatment room anticorrosive usable granite and acid resisting brick, these two kinds of material what?

- RZG garnet is almost insoluble in acid insoluble in alkali, common for the diamond 12 face angle of 38 or four surface features can ensure that different crystal polyhedron particles than other material between ordinary circular or elliptical particles can produce voids more suitable, can play a better effect of filtration and antisepsis.

- Q: The difference between acid and heat resistant lightweight castables and acid resisting bricks

- Acid resistant bricks can be customized according to different environments, and resist acid and alkali brick materials of various acids and bases. And pouring materials basically uniform formula, even if a slight adjustment can not solve the strong acid, strong alkali use environment.Acid resistant bricks can be factory mass customization, the cost is slightly lower, while the casting materials need on-site construction, the cost is slightly higher.

- Q: Construction method of acid proof brick

- Construction methodLining adhesive layer, mortar protection layer: lining carbon brick before, in the bottom board first put a layer of delta =3mm cement whole surface layer, in order to protect the lining layer and avoid mortar joint layer appear blind seam, curing at normal temperature after masonry.Positioning, layout and layout: according to the bottom of the groove size, first play the central cross line, then positioning, line, according to the line for typesetting, painting, cutting and numbering.Lining procedures: masonry procedures from low to high, the first base, the rear wall, the Yin angle, the facade to suppress the plane, Yang Kok plane cover the facade.Masonry method: the bottom and wall are all made by squeezing, kneading and extruding, and they are made by line by line, layer by layer, block by block.The prepared mortar evenly scraping on the three surfaces of carbon brick (i.e., on the back end, and then squeeze (side), rubber hammer) is dense, the ash seam and the combined layer clay full, squeeze out excess clay to eradicate. The surface shall be made of flat and vertical, rows and rows, and the seams between floors and layers shall be staggered.

- Q: Cleaning metal surface rust stain, is it better to weld sulphuric acid or nitric acid?

- Abrasive blasting is the physical cleaning of dry or suspended abrasive particles in the liquid to the surface of metal parts or products to remove corrosion products. Sand blasting can remove rust, oxide, dry dirt, molding sand or paint on metal surface.Abrasives used for dry blasting include metal sand, iron pellets, fine sand, glass, etc.. Factors such as hardness, density, particle size and shape shall be taken into account when selecting specific abrasives.Sandblasting equipment used by: no use of air sand thrown blade or impeller, pressure nozzle set rubidium: suction nozzle device, see second articles. Sand blasting cleaning is a common method of removing the corrosion products such as ferrous oxide and non-ferrous metal surface oxide

- Q: Acid resistant brick lining, engineering scaffolding, how to take?

- Construction preparation, familiar with drawings, specifications, technical disclosure, do a good job of the handover process.

Send your message to us

High Purity Acid Resistant Alumina Ceramic Lining Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords