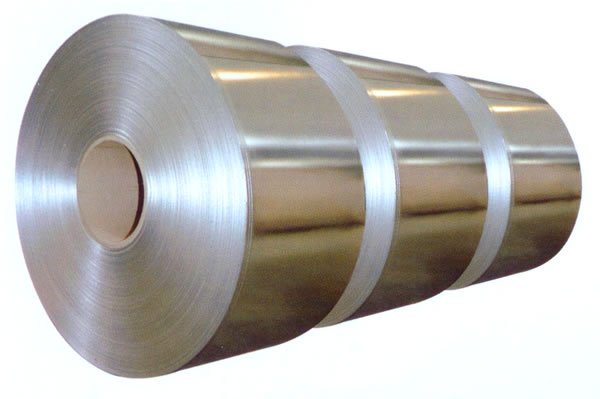

High Preciseness Cold Rolled Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

SPCC | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

SPCD | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

SPCE | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: How are steel products used in the manufacturing of appliances and consumer goods?

- Steel products are used in the manufacturing of appliances and consumer goods due to their durability, strength, and versatility. They are commonly utilized in components such as frames, casings, and structural supports, providing stability and robustness to the final product. Steel's resistance to corrosion also ensures a longer lifespan for appliances and consumer goods. Additionally, steel can be molded and shaped into various forms, allowing manufacturers to create intricate designs and meet specific functional requirements. Overall, steel products play a crucial role in enhancing the performance, reliability, and aesthetics of appliances and consumer goods.

- Q: How do steel products contribute to the infrastructure development of a country?

- Steel products contribute to the infrastructure development of a country in several ways. Firstly, steel is a versatile and durable material that is used in the construction of buildings, bridges, roads, and other vital infrastructure. Its strength and ability to withstand extreme weather conditions make it an ideal choice for these applications. Secondly, steel products such as pipes and cables are essential for the efficient transportation of water, gas, and electricity, ensuring that cities and towns have access to these vital resources. Lastly, the manufacturing and production of steel products create employment opportunities and stimulate economic growth, contributing to the overall development of a country's infrastructure.

- Q: How is steel mesh used in construction?

- Steel mesh is commonly used in construction for reinforcing concrete structures. It is placed within the concrete to provide additional strength and prevent cracking or failure. The mesh helps distribute the load evenly, making the structure more durable and resistant to various forces such as tension and compression. Additionally, it can be used in constructing fences, partitions, or as a safety barrier.

- Q: How are steel products used in the construction of government buildings and administrative centers?

- Steel products are extensively used in the construction of government buildings and administrative centers due to their durability, strength, and versatility. These products offer structural support, allowing for the construction of large and complex buildings. Steel beams, columns, and frames are commonly used to provide stability and withstand heavy loads. Additionally, steel is used for roofing, cladding, and interior partitioning, providing fire resistance and enhancing the overall safety of the structure. The use of steel products in government buildings ensures longevity, cost-effectiveness, and compliance with stringent safety regulations.

- Q: What is the role of steel in the manufacturing of railway tracks?

- Steel plays a crucial role in the manufacturing of railway tracks as it provides the necessary strength, durability, and resilience to withstand the heavy loads and constant wear and tear of trains. It is used to construct the rails, which provide a smooth and stable surface for train wheels to run on. Steel's high tensile strength allows for longer and continuous tracks without the need for frequent expansion joints, ensuring a safer and more efficient railway system.

- Q: What are the different types of steel coils and their applications?

- There are several types of steel coils used in various applications. Hot-rolled steel coils are commonly used in construction, automotive, and general manufacturing industries due to their strength and durability. Cold-rolled steel coils are often used in appliances, furniture, and electrical equipment as they provide a smoother surface finish. Galvanized steel coils, which are coated with a layer of zinc, are primarily used in outdoor structures, automotive parts, and agricultural equipment for corrosion resistance. Lastly, stainless steel coils are used in industries requiring high resistance to corrosion, such as the food processing, medical, and chemical sectors.

- Q: What are the common uses of stainless steel cookware?

- The common uses of stainless steel cookware include cooking various types of food, boiling water, sautéing, frying, baking, roasting, and simmering. Stainless steel cookware is versatile, durable, and non-reactive, making it suitable for everyday cooking as well as more specialized techniques like searing and deglazing.

- Q: How is steel used in the production of storage tanks and containers?

- Steel is commonly used in the production of storage tanks and containers due to its strength, durability, and resistance to corrosion. It is used to construct the shells and structural components of the tanks, providing a reliable and long-lasting solution for storing various liquids and gases. Additionally, steel can be easily fabricated and welded, allowing for customization and efficient manufacturing processes.

- Q: How are steel products used in the water treatment industry?

- Steel products are used in the water treatment industry for various purposes such as the construction of water tanks, pipelines, and treatment equipment. They provide durability, corrosion resistance, and strength, ensuring a reliable infrastructure for storing, transporting, and treating water.

- Q: How is steel used in the production of laboratory equipment?

- Steel is used in the production of laboratory equipment due to its exceptional strength, durability, and resistance to corrosion, making it ideal for manufacturing various tools and instruments used in scientific research and experimentation.

Send your message to us

High Preciseness Cold Rolled Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords