High Dimensional accuracy Cold Rolled Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

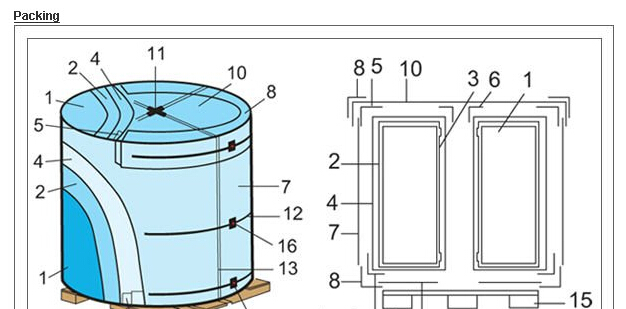

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

St12 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

St13 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

St14 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the challenges in coil leveling for coated steel?

- To achieve high-quality, flat, and smooth coils, several challenges must be addressed in the process of coil leveling for coated steel. The first challenge lies in the potential damage to the coating during leveling. Coated steel coils are typically covered with materials like zinc or paint, which are susceptible to scratching or marring if mishandled. The leveling process involves passing the coil through a series of rolls, which can cause friction, abrasion, or other mechanical harm to the coating. Therefore, it is crucial to meticulously control the speed, pressure, and alignment of the rolls to minimize coating damage. The second challenge stems from the variations in thickness across the coil. Coated steel coils often exhibit thickness discrepancies due to inherent material properties or production methods. These variations can lead to uneven leveling, resulting in coils with waviness or inconsistent flatness. Achieving uniform leveling across the entire coil surface is vital to ensure consistent quality and appearance of the final product. Another challenge in coil leveling for coated steel is the possibility of shape distortion. The coating processes can introduce stresses into the steel, causing the coil to warp or distort during leveling. This distortion can lead to coils with irregular edges or uneven flatness. Proper control of leveling process parameters, such as the number of passes and applied tension, is necessary to minimize shape distortion. Furthermore, the coil leveling process can generate internal stresses in the steel, especially in cold-rolled or heat-treated coated steels. These internal stresses can result in coil spring-back, where the coil attempts to revert to its original shape after leveling. Spring-back can cause coils with undesired curvature or inconsistent flatness. Effective strategies, such as stress relief annealing or employing counteracting leveling techniques, are essential to minimize spring-back and achieve the desired flatness. Lastly, handling and storing coated steel coils pose challenges in maintaining the quality of the leveled coils. Coated steel coils are sensitive to environmental conditions, such as humidity, temperature, and exposure to corrosive substances. Proper storage and handling practices are crucial to prevent coating damage, rust, or other forms of deterioration that can occur during transportation or storage. In conclusion, the challenges in coil leveling for coated steel involve minimizing coating damage, addressing thickness variation, controlling shape distortion and spring-back, and ensuring proper handling and storage. Overcoming these challenges necessitates precise control of process parameters, the application of suitable leveling techniques, and strict adherence to quality control measures throughout the entire process.

- Q: Are steel buildings or homes better then wooden buildings? Why?

- Steel is better than wood. Steel can support more weight than wood. Steel is also much more durable than wood. Termites and rot are not a problem, which results in lower maintenance cost later. Also, wood can rot and warp whereas steel will not. Steel is also more economical than wood. The construction requires less labor, and as a result the labor cost is much lower. Steel is fire resistant, which will lower insurance costs.

- Q: What are the different grades of steel used for making coils?

- The different grades of steel used for making coils vary depending on the specific application and requirements. Common grades include low carbon steel (e.g., ASTM A36), medium carbon steel (e.g., ASTM A572), high carbon steel (e.g., ASTM A516), and stainless steel (e.g., AISI 304). Each grade offers different properties such as strength, ductility, corrosion resistance, and heat resistance, allowing manufacturers to choose the most suitable grade for their coil production needs.

- Q: like, what can steel make?

- buildings bridges automobiles elevators railroads and railroad equipment appliances and many many more. Steel is used almost everywhere. reference: Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars (Despite growth in usage of aluminium, it is still the main material for car bodies.), steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.[66] Other common applications include shipbuilding, pipeline transport, mining, offshore construction, pipeline transport, aerospace, white goods (e.g. washing machines), heavy equipment (e.g. bulldozers), office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour (better known as rolled homogeneous armour in this role). .

- Q: How do steel coils contribute to the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they provide structural support and enhance the durability of various components. They are commonly used in transformers, motors, and generators, where they serve as the core material due to their magnetic properties. The steel coils help to create and maintain magnetic fields, ensuring efficient energy transfer and enhancing the overall performance of electrical equipment.

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- Steel muscles is very nice, but working on your contractions is a longer lasting necessity. In my opinion.

- Q: What are the challenges in coil leveling for high-strength steel?

- Coil leveling for high-strength steel poses several challenges that need to be addressed in order to achieve optimal results. One of the main challenges is the inherent hardness and strength of the steel itself. High-strength steel is specifically designed to have enhanced mechanical properties, such as tensile strength and hardness, which make it more difficult to deform and shape. The high-strength nature of the steel requires specialized leveling equipment that can apply sufficient force to overcome its resistance to deformation. This may involve using stronger and more durable leveling rollers or increasing the pressure exerted during the leveling process. Failure to apply the appropriate force can result in incomplete leveling, leading to residual stress and potential dimensional inaccuracies in the final product. Another challenge in coil leveling for high-strength steel is the potential for springback. Springback refers to the tendency of the material to revert to its original shape after being deformed. High-strength steel is particularly prone to springback due to its higher elastic modulus. This can result in uneven leveling and dimensional variations in the coil. To mitigate springback, advanced leveling techniques may be employed, such as overbending or pre-bending the steel. Overbending involves bending the steel beyond the desired level, allowing it to spring back to the desired shape. Pre-bending, on the other hand, involves intentionally bending the steel in the opposite direction before leveling it, counteracting the effects of springback. These techniques require precise control and expertise to ensure accurate leveling. Additionally, high-strength steel often has a more pronounced yield point, which is the stress level at which permanent deformation occurs. This can make it more challenging to achieve consistent and uniform leveling throughout the coil. Proper adjustment of the leveling equipment and careful monitoring of the leveling process are necessary to address this challenge effectively. Furthermore, high-strength steel coils are often thinner and more sensitive to surface imperfections. The leveling process must be carefully regulated to avoid causing damage to the steel surface, such as scratches or indentations. This may involve utilizing softer leveling rollers or implementing protective measures, such as cushioning materials or coatings, to prevent surface defects. In summary, the challenges in coil leveling for high-strength steel revolve around its inherent hardness, springback tendencies, yield point behavior, and sensitivity to surface imperfections. Overcoming these challenges requires specialized equipment, advanced leveling techniques, precise control, and expertise to ensure accurate and high-quality leveling results.

- Q: How are steel coils used in the production of agricultural fencing?

- Steel coils are used in the production of agricultural fencing by being processed and shaped into wire strands that are then woven or welded to create the fence panels. These coils provide the necessary strength, durability, and rigidity required for effective and long-lasting agricultural fencing solutions.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- Most of the 300 series stainless metals are not magnetic, but if it is cast, it is magnetic. Welds are considered casting, so the welds are magnetic even though the items that are welded together are not. The 400 series stainless may have a few types that are magnetic. I suppose generally the hardenable factor has a bearing if you consider that 400 series can be hardened more readily than the 300 series. Source: Working in metal fabrication shops.

Send your message to us

High Dimensional accuracy Cold Rolled Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords