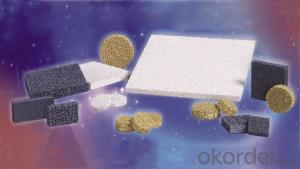

High Porosity Ceramic Filter Plate - High Quality Alumina Ceramic Foam Filters Series

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter has the advantages of high porosity, good thermal shock resistance,high mechanical strength, large specific surface and stable chemical property. In addition, with the excellent function of filtering, residuum collection and absorption, it can remove the impurities of 1-10μm efficiently. The outstanding three dimensional structure can reduce the turbulence and extrude the air in mould filling, provide consistent and rapid metal flow, improve the casting quality prominently.Ceramic Foam Filter can also be applied in gas treatment at high temperature, carrier of catalyzer, solid thermal exchange and special filling for chemical industry.

With more than ten years of research and development, enriches its product scope with different series of foam filters such as Alumina, Silicon Carbide and Zirconia.

Alumina foam filter (JG-1): For molten metal filtering under the temperature of 1200℃;

Silicon Carbide foam filter (JG-201, JG-202): For molten metal filtering under the temperature of 1550℃

Zirconia foam filter (JG-3): For molten metal filtering under temperature of 1700℃.

APPLICATION OF CERAMIC FOAM FILTER

Selection of ceramic foam filter

1) Selection of pore size is based on the weight and material of casting, regularly 10ppi for Stainless Steel; 10ppi for Ductile Iron; 20ppi for Grey Iron; 15ppi, 20ppi and 30ppi for non-ferrous alloy castings:

2) Foam filter size is decided by the sculpt, fusion and the characteristic of the ceramic foam filters.

3)'Ceramic foam filters should be fixed in the runner and ensure its uniform pressure.

4) Strictly control the pouring pressure and reduce the impact of hot molten metal.

5) Ceramic foam filters under ultra-high temperature are prohibited.

6) Strictly avoid using the ceramic foam filters to control the flow speed of molten metals

Attentions for store and application

Ceramic foam filters should be stored in dry environment to avoid moisture. Ceramic foam filters are fragile materials, rough handling in transportation is prohibited. It is recommended to blow the scum with compressed air before using

The advantage of application ofceramic foam filter

1) Reduce the defective rate and improve the casting yield.

2) Reduce the machining allowances and improve machinability of casting.

3) Improve the mechanical property of casting

4) Simplify pouring systems and improve the utilization ratio of mould

TYPICAL INSTALLATION OF CERAMIC FOAM FILTERS

Based on the characteristic of casting and the filters' working condition, ceramic foam filters can be fixed in different parts of the pouring system

1、Installation in the pouring cup: Commonly for precision casting and the casting of iron model covers the granulated substance

2、Horizontal installation in vertical runner: For small part with few pouring molten iron, especially for casting system with a vertical runner located at mould center and multiple branches of horizontal runner

3、Horizontally installation in horizontal runner: It makes molten metal casting stable, avoiding directly impacting the filter. This will increase slag blocking ability and make installation convenient.

4、Vertically installation in horizontal runner: To increase molten metal flow speed and enhance the filling capacity. Since molten metal directly impacts the fillers, the impact resistance of filters should be considered

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Generally, the vacuum degree of ceramic filter is about -0.08MPa. Sufficient vacuum pressure is only a prerequisite for a good ceramic suction effect. Besides vacuum, the other factors may affect the suction effect:Vacuum display table fault, the difference between the display value and the actual data is great.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- Ceramic filter is a new and efficient dehydration equipment. If users find the ceramic filter board surface suction effect is poor, or even do not suck slurry, we should promptly investigate the causes, so as not to affect production efficiency.

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

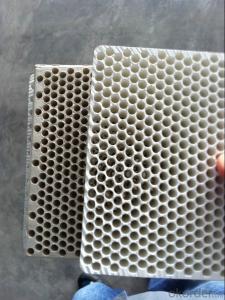

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: What is the backwashing pressure of the ceramic filter?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like syringe pumping), and then through the scraper discharge, after unloading, ceramic filter machine is complete a cycle in the absorption slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles blockage will make the filter medium permeability and filtering effect of the loss from the poor, in order to reduce the possibility of blockage ceramic filter, will enter the backwash (this process is like a water jet injector). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

- Q: How should the static and dynamic sealing points of the ceramic filter be leaking?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor.

Send your message to us

High Porosity Ceramic Filter Plate - High Quality Alumina Ceramic Foam Filters Series

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords