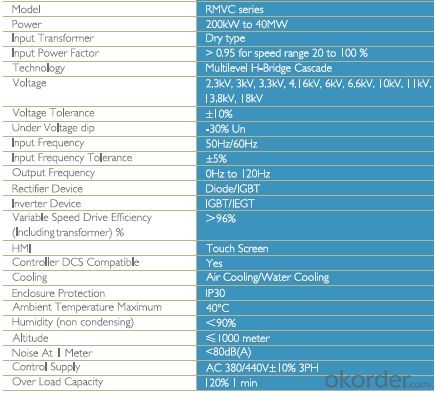

High Medium Voltage Drive 3KV 1000KW RMVC4000-A030/1250 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: How can a variable speed multi - speed three - phase asynchronous motor be controlled by a frequency converter?

- With the inverter control, then you do not need multi-speed motor, because the inverter can directly control the motor speed, if the two together, the formation of a waste.

- Q: Motor nameplate on the standard 2P, I set the number of motor pole in the inverter, is set 2 or 4 pole?

- 1,2P refers to the number of motor poles, so it is certainly even 2, if the inverter is set to determine the number of motor poles, please write 2P value, if 2P = 4, please write 4 3, look at the nameplate on the motor rated speed for how much, you can confirm the number of motor poles. (N = 60f / p) P: pole pairs

- Q: What are the differences and links between the soft starters and the frequency converters, and their respective principles and uses?

- The soft starter is activated by adjusting the voltage and current, and the frequency converter starts the motor by changing the frequency of the power supply. The soft starter can theoretically smooth and gradually start the motor to the maximum speed. No impact current (ordinary start-up current is 6-7 times the rated current) The inverter is best suited for tap water and fans, etc. The soft starter is not suitable for everything except for heavy load start.

- Q: Servo control system can give the inverter signal,

- but want two motor synchronization, it should be impossible, the converter does not reflect so fast, and the speed is not so stable.

- Q: Laptop adapter heat

- In fact, as long as the power adapter temperature is within the design range, that is, the temperature in the normal range, the general is not dangerous! So why is the power supply hot? What kind of temperature range is the normal range? Switching power supply conversion efficiency can only reach 75% -85% or so. The answer is here. Switching power supply conversion efficiency is high enough, it is still difficult to find a better way to convert. Switching power supply in the voltage conversion, a part of the energy loss, in addition to a small part of the loss in the form of waves, the majority of the way out of the heat. Switching power supply power is missing, the loss of energy is also missing, the power of the heat is also large. This is why the desktop power supply to add a fan for cooling reasons. We may wish to count, a 100W switching power supply, in the use of how much energy loss in the above!

- Q: Laptop power supply 20V 3.5A can use 20V 4.5A power adapter Mody, what impact?

- can. For a constant voltage power adapter, the following requirements can be replaced: The replacement of the new power adapter output voltage is the same as or similar to the output voltage of the original power adapter. Replacement of the new power adapter maximum output current is not less than the original power adapter maximum output current. Replacement of the new power adapter with the original power adapter interface definition and shape the same. Replacement of the new power adapter Other non-major electrical performance indicators, not less than the original power adapter of the corresponding indicators. Notebook original power adapter nominal rated current of 3.5A, indicating that the laptop itself does not exceed the input current of 3.5A, for the rated current of 4.5A power adapter, the drive is no problem in this load.

- Q: What is the frequency of `30 points

- AC are frequency, China is 50 Hz, is in a second amplitude of 50 times. To change this frequency, it is necessary to use some electronic components to change the current frequency. General frequency conversion for the tributary motor speed more. So that some equipment can be stepless. Principle, see the first floor just fine, copy the more detailed.

- Q: There is no inverter comes with simple PLC programming function

- Inverters are generally digital input, and analog input, a digital output, etc., can also be controlled by means of communication. Digital input can be used as a positive and negative and reset the alarm, the analog input can be given as a speed, and how to use the inverter to see the specific model. Take the Siemens inverter, MicroMaster420,567 terminal 3 digital input, 8 for the 24V, 9 for the 0V, you can usually open the point on the 8th 24V back to 567, as a digital input, you can also directly into the switching power supply Of the 24V, but the switch power supply 0V and 9 terminals connected to the potential, or the inverter may not be able to identify the outside world 24V. (DP communication, USS communication, etc.), with the terminal input on the P0700 = 1, the user can set the command source, the panel can be input, 2, P0701 to P0703 corresponding to the three digital functions: parameters set to 1 forward, 2 for the reverse ... ... a lot of features and control methods, see the corresponding product manual like

- Q: How to choose a Siemens inverter for a 5.5KW three-phase motor (2 pole)?

- Siemens frequency conversion dedicated input / output filter, reactor, you contact us but smell it, the quality is guaranteed. We look forward to cooperation.

- Q: 90KW inverter start 90KW, 4-pole motor and 6-pole motor j What is the difference? The inverter can be used for it?

- Two motors can use the same frequency converter, but the motor nameplate data through the parameters to adjust the input when the inverter should pay attention to some

Send your message to us

High Medium Voltage Drive 3KV 1000KW RMVC4000-A030/1250 VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches