High Density Polyethylene Geocell with Bitumen Geomembrane CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

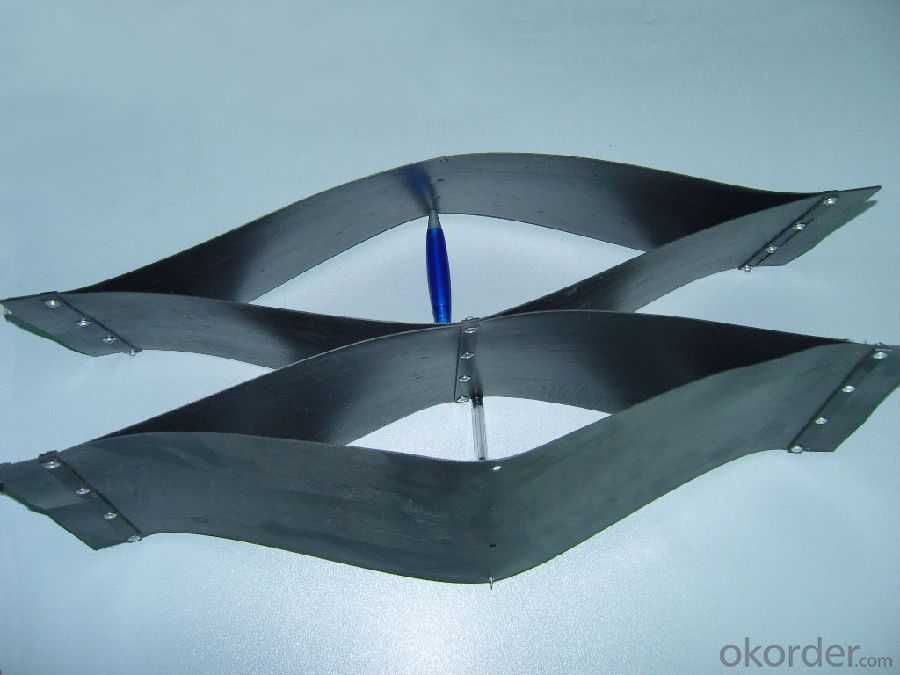

Description Of High Density Polyethylene Geocell:

Our geocell canbe made of PP/HDPE/plastic,

length:6.22m ;

thickness: 1-2mm

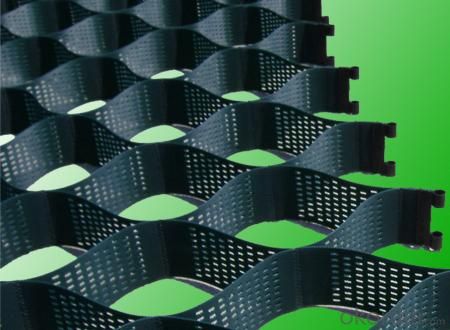

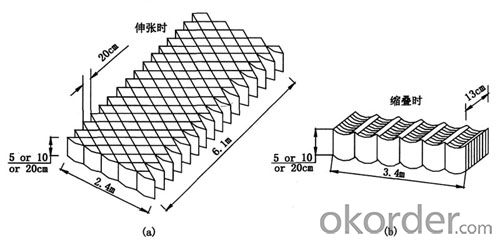

Geocell is a net-shaped cell structure made by welding high intensity thermoplastic sheet. It is flexible folded during service, and forming into struct with powerful lateral confinement and rigidity.

It can be used as cushion coat to strengthen loading capacity of weak ground or slope protection

structure, as well as stop structure, and so on.

Main Features of High Density Polyethylene Geocell:

1. Fix railway ground .

2. fix weak ground of roads .

3. block loading capacity.

4. treat river way of shallow water.

5. act as support in pipeline and sewer.

6. act as comprehensive block stopping land sliding and bearing loading capacity.

7. act as independent wall, dock and break-water.

8. treat desert, beach, riverbed and bank.

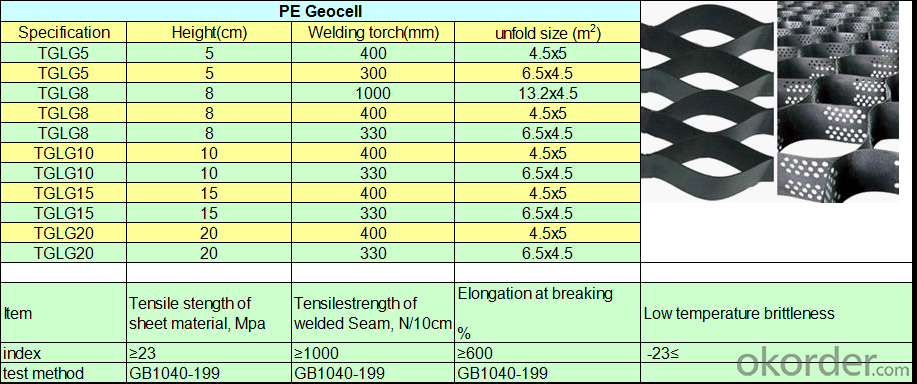

Specifications of High Density Polyethylene Geocell:

1.TGLG5 TGLG8 TGLG10 TGLG15 TGLG20(CM)

2.Stretch size :4mx5m or 6m x7m or at your request.

3. General roadbed reinforcement with 330 mm, 400 mm.

Slope protection with 500 mm, 660 mm

4.Executive standard:GB/T19274-2003

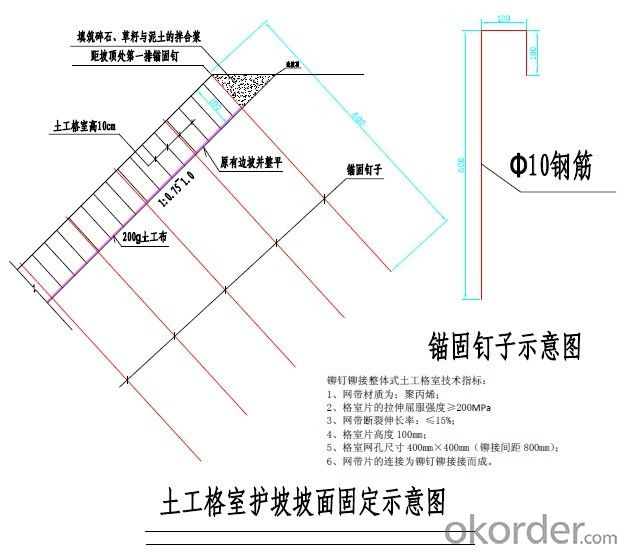

Technical specification of geocell

Applications of High Density Polyethylene Geocell:

1. processing half fill Semi roadbed

build up the embankment on the ground on the slopes of the natural slope ACTS in 1:5, supporting subsoil should dig the steps, The step width shall be less than 1 m, when building or rebuilding roads widened by installments, Convergence between the new and old roadbed fill slope ,should dig the step, high grade highway width is 2 m, laid large geocell in each of the steps horizontally, using the large geocell of their own facade confining reinforcement effect, better solve the problem of uneven settlement

2. subgrade in wind drift sand region

Sand subgrade should be given priority to with low embankment, region filling height not less than 0.3 m. generally due to its low subgrade, sand subgrade construction in professional requirements and heavy load, adopting large chamber loose packing confining effect, can be in limited the height of the roadbed with high stiffness and strength, to inherit the load stress of large vehicles.

3. Reinforced back subgrade soil

Using large geocell can better achieve the goal of abutment back reinforced , can generate enough friction between the geocell and packing . and effectively reduce roadbed uneven subsidence, finally can effectively relieve the abutment jump car "disease early impact damage of bridge deck.

4. subgrade in permafrost region

In permafrost regions fill roadbed construction, should reach a minimum filling height in order to prevent or cause a frozen layer ceiling Frothing decreased, resulting in an excess of embankment settlement occurs. Geocell unique overall unconfined facades reinforced effect and effectively implemented, can ensure a minimum filling height in some special area to the maximum extent, and to fill a high-quality strength and stiffness.

5. The collapsibility loess roadbed treatment

When the highway and the highway collapse loess and loess lot better compression by wet, or foundation bearing capacity is lower than the high embankment to allow third-party vehicle load and weight of pressure embankment, subgrade bearing capacity requirements should also for processing, then the superiority of Geocell on manifest is no doubt.

IMages of Plastic Geocell/HDPE geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Is black HDPE geomembrane eco-friendly?

- Raw material of HDPE geomembrane is HDPE particles, adding carbon?black to become black. It is buried underground to prevent hazardous liquid leakage. So HDPE geomembrane can be considered as environmentally friendly.

- Q: Can geomembrane HDPE replace waterproof roll modified asphalt sbs to be used in architecture?

- Does not meet the SBS construction conditions SBS can not conduct construction on the waste plant, because the base under the waste plant is soil layer; flat

- Q: How to choose the stick membrane for decoration?

- Firstly, look at the design and colour. In order to identify whether the household colourful film is good or bad, you should first check whether the color is even, whether there is chromatism and bleeding. Usually a pattern is better when the pattern is more clear. In the next step, you should look at the tenderness, which is mainly for non-woven fabrics and wall coverings, etc. You have to look at both sides. Usually the quality is better if density of the surface wove is higher. Secondly, touch it and feel its toughness. Some people think that household colourful film is better when it is thicker, which is a misunderstanding. The quality is related to the quality of paper, production technique and toughness, and thickness, and not directly related to the thickness. When you identify the wallpaper by hand, you should touch it and feel and toughness, particularly for flocking wallpapers. They are most likely to feel the difference between good and bad. Usually the quality and toughness is better when it is softer. But when domestic and imported products that are made of the same material are compared, the imported ones will be relatively thick and of higher density. Third, smell it. Inferior household colourful film has bad smell. In addition, the real environmentally friendly film has no smell, but if it is made of inferior materials, it will have a pungent smell. You can smell it when coming close to it. Fourly wipe it. Wear-resisting and soiling-resisting should be tested. It is recommended that consumers draw some lines on the paper and the wipe them in the purchase process. Generally high quality colorul decoration film can easily be cleaned even if the surface is bumpy, but if it is of low quality, it is easy to be scraped or not easy to be cleaned.

- Q: What are the advantages of using geomembranes in bioremediation projects?

- There are several advantages of using geomembranes in bioremediation projects. Firstly, geomembranes act as a barrier, preventing the migration of contaminants into surrounding soil and groundwater. This containment helps to control and concentrate the bioremediation process, allowing for more efficient treatment of the contaminated area. Additionally, geomembranes provide a stable and consistent environment for the growth of microorganisms involved in bioremediation, enhancing their effectiveness. They also prevent the loss of valuable nutrients and organic matter during the remediation process. Lastly, geomembranes offer long-term durability, ensuring the success and sustainability of bioremediation projects over time.

- Q: What are the advantages of using geomembranes in aquaculture facilities?

- There are several advantages of using geomembranes in aquaculture facilities. Firstly, geomembranes provide a protective barrier against seepage and leakage, preventing the loss of water and valuable resources. Secondly, they help maintain optimal water quality by preventing the intrusion of contaminants and pollutants. Additionally, geomembranes offer a flexible and durable solution, allowing for easy installation and customization to different facility designs. This can help reduce construction costs and increase operational efficiency. Lastly, geomembranes minimize the risk of disease transmission and improve biosecurity, ensuring a healthier and more sustainable environment for aquaculture operations.

- Q: How do geomembranes provide insulation in roofing systems?

- Geomembranes provide insulation in roofing systems by acting as a barrier between the roof and the external environment. They are made of materials with high thermal resistance, such as PVC or EPDM, which help to reduce heat transfer and maintain a stable temperature within the building. Additionally, geomembranes can be installed with insulation layers underneath, further enhancing their insulating properties by preventing heat loss or gain through the roof.

- Q: What are the advantages of using geomembranes in floating baffles?

- There are several advantages of using geomembranes in floating baffles. Firstly, geomembranes provide excellent durability and strength, making them highly resistant to punctures and tears. This ensures that the floating baffles maintain their structural integrity and effectiveness over time. Secondly, geomembranes are impermeable, meaning they prevent the passage of liquids and gases. This is crucial in floating baffles as it helps to contain and control the flow of water or other fluids within the desired areas. It also prevents the unwanted mixing of different fluids or contaminants, enhancing the overall effectiveness of the baffles. Additionally, geomembranes are flexible and adaptable, allowing them to conform to various shapes and sizes. This makes them ideal for floating baffles, as they can easily be customized to fit specific requirements and configurations. This flexibility also enables easy installation and maintenance of the baffles. Furthermore, geomembranes are resistant to UV rays, chemicals, and environmental degradation, ensuring their longevity and reliability in harsh conditions. This makes them suitable for floating baffles used in a wide range of applications, including wastewater treatment, pond and lagoon management, and oil spill containment. Overall, the advantages of using geomembranes in floating baffles include durability, impermeability, adaptability, and resistance to various environmental factors. These qualities contribute to the effectiveness and longevity of the baffles, making them a reliable solution for fluid containment and control.

- Q: The geotechnical membrane technology of urban construction?

- According to standards, the geomembrane can be divided into three standard, national standards, national standards II, American Standard (that is urban construction standards). The manufacturers generally use the calendering process is to produce the GB, but the transverse strength is difficult to achieve. Now some big manufacturers began to use the three layer membrane-blowing film equipment. This process can fully compensate for the defects of the calendering process, and it can be a perfect production abroad standard type A, type 2 GB, American Standard, the three standard, full compliance.

- Q: What is film mulching plywood?

- The advantages of film mulching template: large area. The maximum width is 2440*1220,915*1830mm, which reduced joint numbers, and improved the work efficiency of formwork. Do not warp, no deformation, no cracking, good water resistance, high turnover. Easy demoulding, only 1/7 of the steel mould. Light weight: It is more easy to be used in high-rise building and bridge construction. Use frequency: When properly stored and used, it can be used more than 12 times. Concrete pouring: Pouring surface is smooth and beautiful, leaving out twice plastering of walls, and it can be decorated directly which reduced 30% of duration. Corrosion resistance: Won't pollut concrete surface. Good thermal insulation: Conducive to winter construction, and can be used as bending plane template. Good performance in construction: Nails, saws, drilling and other properties are better than bamboo plywood. Small steel plate needs to be processed into template of various shapes according to construction.

- Q: composite geo-membrane's introduction

- composite geo-membrane, it's widely used in canal seepage control project. In recent years, a large number of applications and their effectiveness of geosynthetics in civil engineering, in particular flood rescue project, attracts high attention of engineering and technical staff. For geosynthetics technology, from anti-seepage, filtration, drainage, reinforcement, protection and other aspects, our nation has proposed normative technical requirements, which has greatly accelerated the pace of the popularization and application of new materials. The material is widely used in the irrigation channel anti-seepage project, combined with the construction practice, we will talk about the application technology of geomembrane.

Send your message to us

High Density Polyethylene Geocell with Bitumen Geomembrane CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords