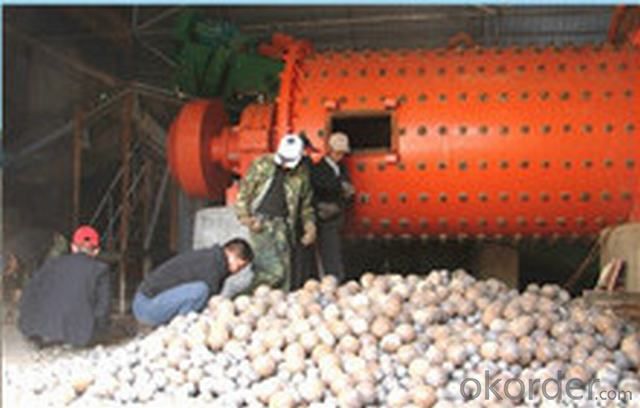

High Chrome Alloy Casting Grinding Ball Made in China with Top Hardness and Low Breakage Rate

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the largest professional manufactory of chrome grinding ball and forged grinding ball in China .Our annual product of chrome grinding ball is about 50000MT.We are take the leading position in Chinese chrome grinding ball industry. We will try our best to supply you with high quality products, reasonable price, timely delivery with satisfactory service as the base of our long time cooperation.

Type and Chemical Composition of High Chrome Alloy Casting Grinding Ball Made in China with Top Hardness and Low Breakage Rate

Material |

C |

Si |

Cr |

Mn |

S |

P |

Cr-22-32% | 2.0-2.8 | ≤1.0 | 22-32 | 0.5-2.0 | ≤0.06 | ≤0.08 |

Cr-17-22% | 2.0-2.8 | ≤1.0 | 17-22 | 0.5-2.0 | ≤0.06 | ≤0.08 |

Cr-15-17% | 2.2-3.0 | ≤1.0 | 15-17 | 0.5-2.0 | ≤0.06 | ≤0.08 |

Cr-11-14% | 2.2-3.2 | ≤1.0 | 11-14 | 0.5-2.5 | ≤0.06 | ≤0.08 |

Cr-5-10% | 2.1-3.2 | ≤1.2 | 5-10 | 0.5-1.5 | ≤0.06 | ≤0.08 |

Cr-1.5-3.% | 2.2-3.5 | ≤1.2 | 1.5-3.0 | 0.5-1.5 | ≤0.06 | ≤0.08 |

Physical Property of High Chrome Alloy Casting Grinding Ball Made in China with Top Hardness and Low Breakage Rate

Material

|

Impact Test Ak.J/cm |

Endurance Test times (5m) | Hardness (HRC) | ||||

Diam25-60mm | Diam70-100mm | ||||||

Quenching | Unquenching | Quenching | Unquenching | ||||

Cr-22-32% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥60 | ≥48 | |

Cr-17-22% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥60 | ≥48 | |

Cr-15-17% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥58 | ≥48 | |

Cr-11-14% | ≥3 | ≥10000 | ≥58 | ≥49 | ≥56 | ≥48 | |

Cr-5-10% | ≥3 | ≥8000 | - | ≥48 | - | ≥48 | |

Cr-1.5-3.% | ≥2 | ≥8000 | - | ≥48 | - | ≥45 | |

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q: What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

- Q: How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa; Mid East;South Asia;Southeast Asia;Eastern Asia;Southern Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

High Chrome Alloy Casting Grinding Ball Made in China with Top Hardness and Low Breakage Rate

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords