High Alumina Raw Materials for Refractory Cements CA50 CA70 CA80 - China Factory Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Alumina Cement |

| SiO2 Content (%): | <0.8-0.5 | Al2O3 Content (%): | 50-80 | CaO Content (%): | 20-35 |

| Refractoriness (Degree): | Super-Class (Refractoriness> 2000°) | Model Number: | CA50, CA70, CA80 | Brand Name: | CNBM |

| Raw Material: | Calcined Aluminum + Limestone | Compressive Strength, Mpa: | Min40 | Bending Strength, Mpa: | Min6 |

| Bulk Density, g/cm³: | Min2.3 | Setting Time: | Fast |

Packaging & Delivery

| Packaging Details: | 1.25kg bag piled or one ton bag on pallet/in case, wooden pallets with plastic film 2. Gross weight: 500-900kgs |

| Delivery Detail: | Around 20 days |

Quality Refractory

Technical: Advanced researching and developing center

Advantages: Quick-drying high speed; High performance of heat resistance; High efficiency of construction

Capacity: 500,000 metric tons per year

Applications: Castable, Firebricks, Furnaces, etc.

Parameters

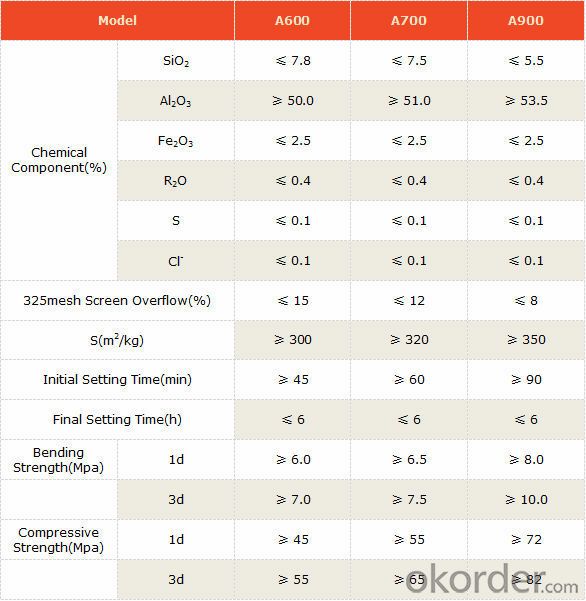

Refractory Cements CA-50

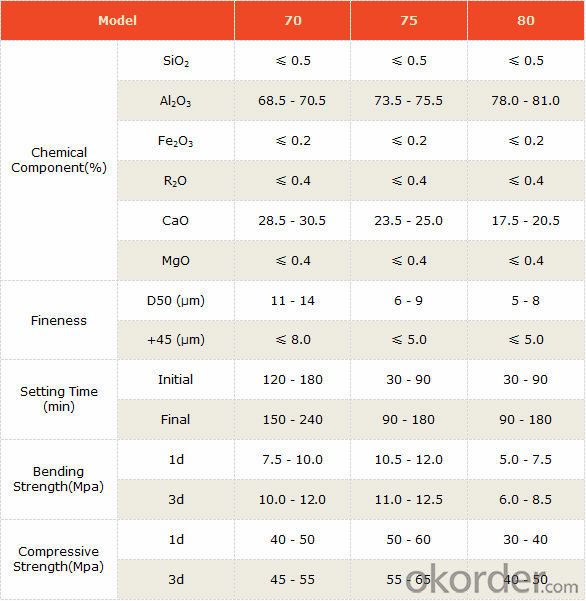

High Purity Refractory Cements CA-70 CA-75 CA-80

More Pictures

Our Service

Our Belief for Customer Service

We hold this belief all the time: We always provide our customers with high quality and competitive products, which can reduce their cost and increase their profit. We will try our best to achieve win-win cooperation and enhance the quality of people’s life together.

- Q: hat kind of fire retardant materials are there

- fire-retardant materials include phosphorus chlorine, bromine and antimony, aluminum, boron based flame retardant, nanometer magnesium hydroxide, high purity industrial grade magnesium hydroxide flame retardant, high purity industrial grade modified magnesium hydroxide flame retardant, composite flame retardant magnesium hydroxide, aluminum hydroxide flame retardant, modified aluminum hydroxide flame retardant, light magnesium-oxide, unsaturated resin flame retardant, silicone rubber flame retardant, polyamide flame retardant, PE flame retardant, PP Flame Retardant, PVC flame retardant, wood flame retardant, special flame retardant for paper, CPE flame retardant, fabric coating rubber flame retardant, flame retardant carpet adhesive, water based coating flame retardant, oily coating flame retardant, power coating flame retardant, ink flame retardant, and heat stabilizer.

- Q: what's the standard of fireproofing material?

- first, the classification of fire resistant levels of buildings, 1, the classification basis of fire resistant levels of buildings, the classification of fire resistant levels of buildings is one of the basic building fire protection technology measures, our national architectural design specification divides fire resistant levels of buildings into first, second, third and fourth class, first class ios the highest and has the most strong fire-resistant capacity, fourth class is the lowest and has the weakest fire-resistant capacity. Fire resistant level of buildings depends on the combustion performance and fire endurance of the components of the buildings. construction components refer to the wall, base, beam, column, floor, stair, suspended ceiling and other basic components of buildings. Combustion performance and fire endurance of building components are shown in table 4-11), the combustion performance of building components are divided into non-combustible component,hard-comnustible component,combustible?component,according to their response to the fire. as for building components, non-combustible component includes wall column and base,etc; hard-comnustible component includes hanging?bracket, suspended ceiling and internal pipe;combustible?component includes doors and windows, suspended ceiling, decoration materials,etc.

- Q: What is the main constituent of refractory brick?

- Primarily magnesium oxide and sodium silicate as binder.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: What a blast furnace refractories generally?

- refractories for blast furnace include carbon brick and silicon-aluminum refractory. BF carbon brick inlcudes half-carbon charcoal bricks, microporous charcoal brick, ultra porous charcoal bricks, graphitic brick and mould pressing charcoal brick. tiles and molded graphite small charcoal bricks. I hope my answers above are helpful to you and your ideal anwers.

- Q: who knows the uses of refratories?

- Physical properties of refractories include structural properties, thermal properties, mechanical properties, usability and operation. structural properties of refractories include porosity, bulk density, water absorption, air permeability, pore size distribution. Refractory thermal properties include thermal conductivity, thermal expansion coefficiency, specific heat, heat capacity, thermal diffusivity, thermal emissivity. Mechanical properties of refractories include compression strength, tensile strength, anti bending strength, torsional strength, shear strength, impact strength, abrasion resistance, creep property, adhesive strength, modulus of elasticity. Refractories are used in various fields of steel, nonferrous metals, glass, cement, ceramics, petrochemical, machinery, boilers, light industry, power, military and other fields of national economy. They are essential materials that ensures the production run and technological development of the above industries, and play an important role in promoting the developemnt of high temperature industrial production. the usability of refractories include refractoriness, softening temperature under a fixed load, linear?change?on?reheating,thermal shock resistant performance,slag resistance, acid resistance, alkali resistance, hydration resistance, carbon monoxide resistance, conductivity, oxidation resistance.

- Q: Is aluminium oxide refractory material?

- Aluminium oxide with 2030?C melting?point is a kind of good refractory material. It can be used as analytical reagent, dehydration and adsorbing?material of organic solvent, catalyst of organic reaction, abraser,polishing agent, raw material of aluminum smelting technology and refractory material. Hope it is helpful to you.

- Q: Who can tell somthing about how to choose fire resistant rating of fire resistance rolling shutter doors?

- Different fire resistant ratings of buildings require different fire endurance of different elements of buildings. According to the fire endurance, fireproof doors can be divided into A-grade, B-grade and C-grade, whose fire endurance should not be less 1.2h, 0.9h and 0.6h respectively. A-grade fireproof doors can be even applied to the material whose fire resistant rating is at secondary level.

- Q: How to make the service life of refractory materials longer?

- Take acid resistant refractory materials as example: the atmosphere should be acidic atmosphere, if used in an environment whose temperature is 1900℃, it would exacerbate the loss of refractory materials, so don’t use overloaded. Second, select the appropriate refractory materials according to the environment. For example, if its operating temperature is 1800℃, generally speaking, the normal use of it according to the instruction of refractory materials would be fine.

- Q: What needs to be paid attention to in the construction of high- temperature refractory mortar?

- In the construction of high-temperature refractory mortar, the following matters should be noted: 1. Take out the organic fire blocking material and knead it into tha shape of a ball. If the temperature is too low, the blocking material along with the package can be put into 40-70℃ warm water and heated before any other operation. 2. During the use of high-temperature daub masonry stove, the minimum mortar joint should be 0.5mm and general mortar joint should be 3-5mm, which can solve the processing and fine grinding of refractory brick on the brick grinder. Besides, it is conducive to the health of workers, and can reduce the masonry effort, ensure the quality and speed up the construction progress. 3. When making urgent repair on the stove, if the joint is much too large, 2-3mm refractory pieces can be appropriately added into the high- temperature refractory mortar, and stirred to fill the joint so as to shorten the repair time and ensure normal production. 4. High- temperature refractory mortar can be painted inside various furnace body, and it should be guaranteed that the surface of the furnace body has no dust or debris before painting. The holes should be cleaned up before plugging. Lay, embed, and fill the blocking material into the gap of holes evenly. For larger holes, flame screen can be used as the framework to increase strength.

Send your message to us

High Alumina Raw Materials for Refractory Cements CA50 CA70 CA80 - China Factory Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords