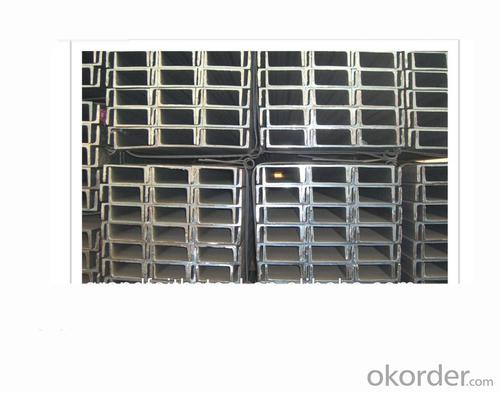

Height 83mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Height 88mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

U Channel Steel the Length Thickness According to the Customer

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

Company Information

which is one of the largest manufacturing bases of Steel Channel in northern China. We are a company that is specialized in producing Stainless Steel Channel、Prime Stainless Steel Channels and so on.

With years of development, our company won the trust and excellent reputation of customers for the quality of our products and sincere service, as well as foreign users of the community.

Please contact me if you are interested in our products and I will try my best to offer you the best goods and service.

- Q: Can steel channels be used for cable management?

- Indeed, cable management can be achieved through the utilization of steel channels. In both industrial and commercial settings, steel channels serve as a prevalent choice for the organization and safeguarding of cables. By ensuring cables remain orderly, shielded from harm or entanglement, and facilitating uncomplicated access and upkeep, steel channels offer a robust and reliable solution. These channels can be affixed to walls or ceilings and are adaptable to accommodate diverse cable types and sizes. Notably, they prove invaluable in environments demanding resilient cable management, including data centers, manufacturing plants, and construction sites.

- Q: How do steel channels contribute to sound insulation?

- Minimizing the transmission of sound waves, steel channels contribute to sound insulation. When utilized in the construction of walls or ceilings, steel channels establish a framework that can be filled with sound-absorbing materials such as insulation or acoustic panels. This combination of steel channels and sound-absorbing materials effectively dampens and absorbs sound energy, subsequently reducing the amount of noise that can permeate through the structure. Moreover, steel channels can also be employed to fashion double or staggered wall systems, thereby enhancing sound insulation by establishing air gaps that act as barriers against sound transmission. In essence, steel channels assume a vital role in sound insulation through the provision of a sturdy foundation and structure for sound-absorbing materials, as well as the creation of a barrier that impedes the travel of sound throughout the building.

- Q: What are the different types of connections used for steel channels in curtain wall systems?

- There are several types of connections used for steel channels in curtain wall systems. Some common types include welded connections, bolted connections, and clip connections. Welded connections involve joining the steel channels together using welding techniques. Bolted connections involve using bolts and nuts to secure the channels together. Clip connections use specialized clips that attach to the steel channels, providing a secure connection. These different types of connections offer varying levels of strength, flexibility, and ease of installation, depending on the specific requirements of the curtain wall system.

- Q: Can steel channels be used for staircase stringers?

- Yes, steel channels can be used for staircase stringers. Steel channels are commonly used for staircase stringers due to their strength, durability, and ability to support heavy loads. They provide a sturdy and reliable framework for the stairs, ensuring stability and safety. Additionally, steel channels can be easily customized and fabricated to fit specific staircase designs and dimensions.

- Q: What are the different methods of forming steel channels?

- There are several methods of forming steel channels, including hot rolling, cold rolling, extrusion, and press brake forming.

- Q: How do steel channels contribute to the durability of a structure?

- Steel channels contribute to the durability of a structure in several ways. Firstly, steel channels are made from a high-strength material which provides excellent resistance to external forces. This means that they can withstand heavy loads, impacts, and vibrations without deforming or breaking, ensuring the structural integrity of the building. Secondly, steel channels are designed with specific shapes and dimensions, allowing them to distribute the loads evenly across the structure. This helps in preventing localized stress concentrations, reducing the risk of fatigue failure over time. By evenly distributing the forces, steel channels can also minimize the potential for cracks or structural deformations, enhancing the long-term durability of the structure. Furthermore, steel channels offer superior corrosion resistance compared to other materials like wood or concrete. Steel is often protected with coatings or galvanized to prevent rust and corrosion, which can significantly extend the lifespan of the structure. This resistance to corrosion is particularly important in environments with high humidity, exposure to saltwater, or industrial pollutants. Another advantage of steel channels is their versatility and adaptability in construction. They can be easily fabricated and customized to fit the specific needs of a structure, including size, shape, and connection details. This flexibility allows for efficient construction and the ability to modify or expand the structure in the future without compromising its overall durability. Lastly, steel channels offer fire resistance, which is crucial for the safety and durability of a structure. Steel has a high melting point and does not contribute to the spread of fire, providing valuable time for occupants to evacuate and minimizing damage to the building. This fire resistance also reduces the need for extensive fireproofing measures, making steel channels a cost-effective solution for enhancing the durability of a structure. In summary, steel channels contribute to the durability of a structure by providing high-strength, even load distribution, corrosion resistance, versatility, and fire resistance. These qualities help ensure the longevity and safety of the building, making steel channels a valuable component in construction.

- Q: What are the standard sizes of steel channels?

- The standard sizes of steel channels vary depending on the specific requirements and standards set by different countries and industries. However, some commonly used standard sizes for steel channels include C3x4.1, C6x8.2, C10x15.3, C12x20.7, C15x33.9, C18x54.7, C20x66, and C24x80. These sizes are measured in inches and represent the dimensions of the channel, such as height, width, and weight per foot.

- Q: What are the different methods of anti-slip treatment for steel channels?

- When it comes to anti-slip treatment for steel channels, there are various methods available, each with its own advantages and suitability for specific purposes. Some commonly used methods include: 1. Grip tape: This cost-effective solution involves applying adhesive-backed tape with a textured surface onto the steel channel. Grip tape is easy to install and offers good traction, making it ideal for areas with light to moderate foot traffic. 2. Anti-slip coatings: These coatings are specially designed to create a rough surface on the steel channel, enhancing slip resistance. They can be applied using a brush, roller, or spray and are made from materials like epoxy, polyurethane, or acrylic. Anti-slip coatings are durable and able to withstand heavy foot traffic, making them suitable for industrial environments. 3. Perforated plates: These steel plates have small holes punched throughout their surface, allowing liquids to drain through and reducing the risk of slipping. Perforated plates are commonly used in outdoor areas or where liquids are present, such as walkways, platforms, or stair treads. 4. Expanded metal: This type of steel sheet is slit and stretched to create diamond-shaped openings. The raised surface of expanded metal provides excellent anti-slip properties, making it ideal for ramps, stair treads, or catwalks. Additionally, expanded metal is durable and resistant to corrosion, increasing its longevity. 5. Welded serrated grating: This method involves welding serrated bars onto a steel channel, creating a rugged surface that improves traction. Welded serrated grating is commonly used in heavy-duty applications where high slip resistance is necessary, such as oil rigs, power plants, or manufacturing facilities. It is crucial to consider the specific requirements of the steel channel and the intended usage when selecting an anti-slip treatment method. Factors like foot traffic, exposure to liquids, and the need for durability should be taken into account to ensure the chosen method is suitable for the application.

- Q: Can steel channels be used in the construction of railings or handrails?

- Yes, steel channels can be used in the construction of railings or handrails. Steel channels are often chosen for their strength and durability, making them a suitable material for supporting and securing railings or handrails. They can be easily fabricated and installed, providing a sturdy structure that can withstand heavy loads and ensure the safety of individuals using the railing or handrail. Additionally, steel channels can be designed in various shapes and sizes, allowing for flexibility in creating different railing or handrail designs to suit specific architectural requirements.

- Q: What is the minimum size of channel steel?

- The minimum size for the 5# channel channel, general specification for 50mm*50mm*3mm 50mm*50mm*4mm 50mm*50*mm5mm 50mm*50mm*6 mm, which is most commonly used, 50*50 is the right number, a digit number. Behind the thickness weight: General cross-sectional area 6.93cm2 theoretical weight 5.44kg/m, 5 channel theoretical weight is 5.438kg/m.

Send your message to us

Height 83mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords