Height 88mm the Thickness 18mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

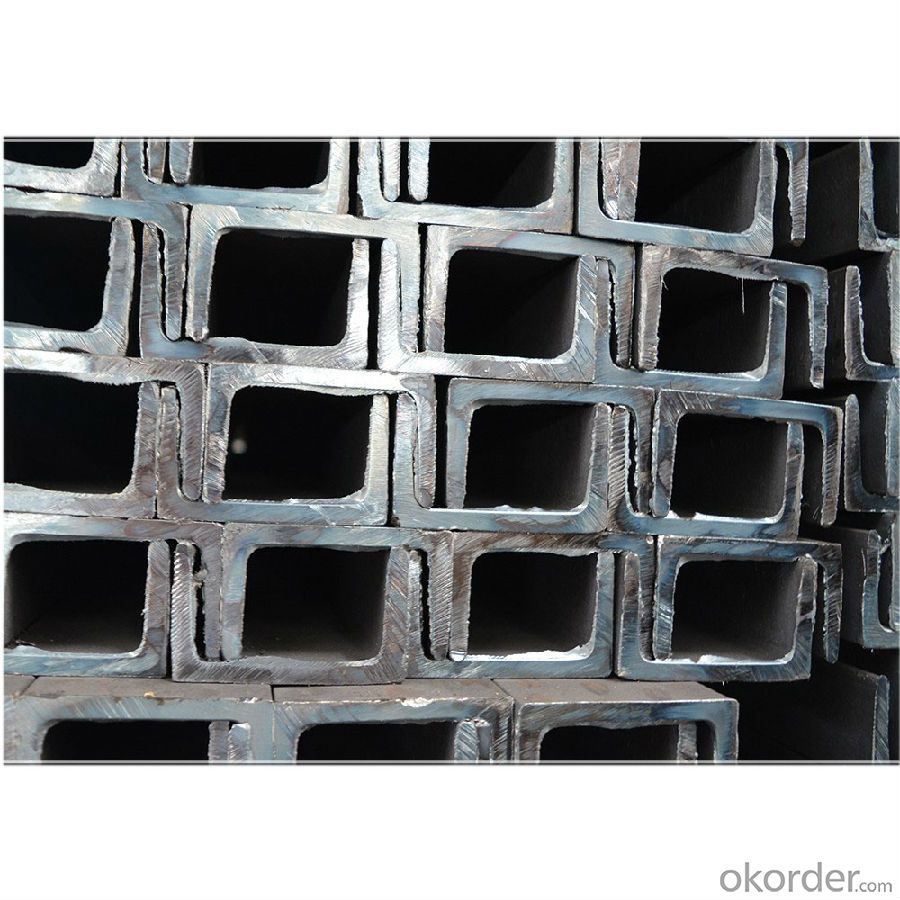

U Channel Steel the Length Thickness According to the Customer

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

Company Information

which is one of the largest manufacturing bases of Steel Channel in northern China. We are a company that is specialized in producing Stainless Steel Channel、Prime Stainless Steel Channels and so on.

With years of development, our company won the trust and excellent reputation of customers for the quality of our products and sincere service, as well as foreign users of the community.

Please contact me if you are interested in our products and I will try my best to offer you the best goods and service.

- Q: Can steel channels be used in commercial construction?

- Yes, steel channels can be used in commercial construction. Steel channels provide structural support and are commonly used in framing systems, roof trusses, and as structural elements in walls and floors. They are versatile, durable, and offer excellent load-bearing capabilities, making them suitable for various commercial building applications.

- Q: Are steel channels suitable for use in corrosive environments?

- Depending on the steel type and specific environmental conditions, steel channels can be used in corrosive environments. For instance, stainless steel channels are highly resistant to corrosion due to chromium and other alloying elements. These channels are commonly used in industries like chemical processing, marine, and food processing, where exposure to corrosive materials or environments is frequent. However, not all steel channels are equally suited for corrosive environments. Carbon steel channels, for example, are more prone to corrosion and may need additional protective measures like coatings or regular maintenance to prevent rusting. In extremely corrosive environments, specialized alloys like duplex or super duplex stainless steel channels may be required for optimal corrosion resistance. Furthermore, factors such as temperature, humidity, and the concentration of corrosive agents play a significant role in determining the suitability of steel channels in corrosive environments. Seeking guidance from corrosion engineers or specialists can assist in selecting the appropriate steel type and protective measures to ensure the longevity and performance of steel channels in such environments.

- Q: How do steel channels contribute to the overall energy performance of a building?

- Steel channels can contribute to the overall energy performance of a building by providing structural support and thermal efficiency. They help in reducing energy consumption by providing a strong framework for insulation materials, which prevents heat transfer and minimizes thermal bridging. Additionally, steel channels can be used for the installation of energy-efficient systems such as HVAC, lighting, and renewable energy technologies, further enhancing the building's energy performance.

- Q: Which kind of wind resistance is better for square tube, square tube or channel steel?

- Square pipe and channel steel that load-bearing better 1, the same thickness and area, square superior to channel. 2, if the channel is closed to a rectangular tube, then the channel is better than the square tube.

- Q: What is the typical lifespan of steel channels?

- The typical lifespan of steel channels can vary depending on various factors such as the quality of the steel, environmental conditions, and maintenance practices. However, with proper care and maintenance, steel channels can have a lifespan of several decades or even longer.

- Q: How do steel channels contribute to the stability of cantilevered structures?

- There are several ways in which steel channels contribute to the stability of cantilevered structures. Firstly, their high strength and durability make them ideal for supporting heavy loads and resisting external forces. When used as a structural component in cantilevered structures, they provide the necessary support and stability to counteract the bending moments and shear forces that act on the structure. In addition, the U-shaped cross-section of steel channels enhances their load-bearing capacity and resistance to bending. This shape allows for a more efficient distribution of forces, preventing excessive deflection and ensuring the structural integrity of the cantilever. Steel channels are also commonly used in combination with other structural elements, such as beams and columns, to create a rigid framework. This framework provides additional support and stiffness to the cantilevered structure, preventing any excessive movement or deformation. Moreover, the versatility of steel channels allows for various configurations and connections, enabling engineers to design cantilevered structures with different shapes and sizes to meet specific requirements. This adaptability ensures that the structure can withstand different loads and environmental conditions, enhancing its overall stability. Finally, steel channels can be precisely fabricated, ensuring accurate alignment and assembly during construction. This precision minimizes any potential weak points or gaps in the structure, further enhancing its stability and safety. In conclusion, steel channels significantly contribute to the stability of cantilevered structures by providing high strength, load-bearing capacity, and resistance to bending. Their U-shaped cross-section, versatility, and precise fabrication also play crucial roles in ensuring the overall stability and integrity of these structures.

- Q: Can steel channels be used for equipment enclosures?

- Certainly! Steel channels are suitable for equipment enclosures. These structural components are commonly employed to offer stability and support to different structures, such as equipment enclosures. Made from sturdy and long-lasting steel materials, they are perfect for shielding equipment from external factors and potential harm. Steel channels can be effortlessly tailored and manufactured to fit the precise dimensions and specifications of the equipment enclosure. Moreover, they can also be reinforced with extra steel components to enhance the overall strength and security of the enclosure. In conclusion, steel channels offer a dependable and resilient solution for constructing equipment enclosures.

- Q: Are steel channels available in non-standard sizes?

- Yes, steel channels are available in non-standard sizes.

- Q: What are the different load combinations considered for steel channels?

- The different load combinations considered for steel channels depend on the specific application and design requirements. However, in general, load combinations for steel channels typically include combinations of dead loads, live loads, wind loads, seismic loads, and other applicable loads. Dead loads refer to the permanent or static loads that are constantly acting on the structure, such as the self-weight of the steel channel itself, fixtures, and any other permanent elements attached to it. Live loads, on the other hand, are variable loads that are not permanently acting on the structure and can include things like people, furniture, equipment, or any other movable loads. Wind loads are important to consider for structures exposed to wind, and they account for the pressure and suction forces exerted by the wind on the steel channel. Seismic loads, or earthquake loads, are considered in areas prone to seismic activity and account for the horizontal and vertical forces generated during an earthquake. In addition to these primary load types, other loads such as snow loads, dynamic loads, impact loads, and thermal loads may also need to be considered depending on the specific design requirements and the intended use of the steel channel. To determine the appropriate load combinations, engineers typically refer to relevant building codes, standards, and design guidelines that provide guidance on load combinations for different applications and regions. These codes and standards ensure that the steel channel is designed to safely carry the expected loads without failure or excessive deformation.

- Q: Can steel channels be used in renewable energy installations?

- Yes, steel channels can certainly be used in renewable energy installations. Steel channels are commonly used in construction and engineering projects due to their strength, durability, and versatility. In renewable energy installations, such as solar or wind power projects, steel channels can be used in various ways. For example, steel channels can be used to support and mount solar panels. They provide a stable and secure structure for the panels, ensuring that they are properly positioned to maximize sunlight absorption. Steel channels can also be used to create frames and mounting structures for wind turbines, providing a strong foundation for the blades and tower. Additionally, steel channels can be used in the construction of transmission and distribution infrastructure for renewable energy. They can be used to create support structures for power lines, ensuring the safe and reliable transmission of electricity generated from renewable sources. Furthermore, steel channels can be used in the manufacturing of various renewable energy equipment and components. They can be used to create frames, brackets, and other structural components for solar inverters, battery storage systems, and other renewable energy devices. Overall, steel channels offer a cost-effective and reliable solution for various applications in renewable energy installations. Their strength, durability, and versatility make them suitable for supporting, mounting, and constructing various renewable energy equipment and infrastructure.

Send your message to us

Height 88mm the Thickness 18mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords