Geotextil Rollo HDPE High Strength Geocell for Parking Pot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE High Strength Geocell:

Geocells are engineered for protection and stabilization applications. They are often used to help improve the performance of standard construction materials and erosion-control treatments.

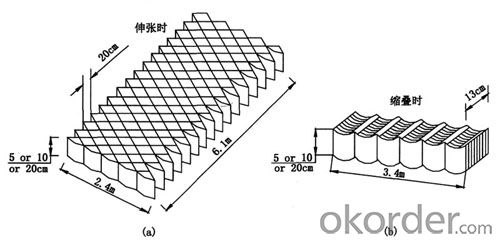

Geocell products are three-dimensional, expandable panels made from high-density polyethylene (HDPE), polyester or another polymer material.

Main Features of HDPE High Strength Geocell:

1. A deal and a half to fill half roadbed

In Acts on a natural slope of the ground: the time when the construction of the embankment slope 5, embankments should be dug basement stairs, step width of not less than 1M, phased construction or alteration road widening, the convergence of the old and the new embankment fill slope should be open dig stairs, stairs highway width is generally 2M, at each step horizontal surface laying Geocell, Geocell own use facade unconfined reinforced effect, a better solution to the problem of uneven subsidence.

2, sand subgrade

Sand subgrade should be dominated by a low embankment, filling height is generally not to be less than 0.3M. Due to sand roadbed subgrade construction and professional requirements of low weight bearing, using Geocell can play loose filler unconfined role in limited the high level of protection embankment has a high stiffness and strength to withstand the load stress of large vehicles.

3, reinforced embankment abutment

Using Geocell can better achieve the purpose of abutment back stiffened, and filler between Geocell can generate enough friction, reduce uneven settlement between the roadbed and structures, and ultimately to effectively alleviate the "jump abutment car "diseases of early deck of impact damage.

Specifications of HDPE High Strength Geocell:

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Seam Peel Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(N/Mpa) |

Flat and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.1/1.2 | ≥100 | ≥120 | ≥20 |

Flat and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.1/1.2 | ≥100 | ≥120 | ≥20 |

Embossed and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5 | ≥100 | ≥120 | ≥20 |

Embossed and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5 | ≥100 | ≥120 | ≥20 |

Remarks: Width of the product can be made according to the customer’s demand, and the other special standards will be carried out by agreement or contact | ||||||

Applications of HDPE High Strength Geocell:

1To stable the roadbed of highway/railway.

2.To bear the load of dyke, retaining wall.

3.To improve the watercourse of shallow river.

4.To support the pipeline and sewer.

5.To be used as independent wall, wharf and breakwater, etc..

6.To be used for the regulation of the desert, beaches, river bed and river bank.

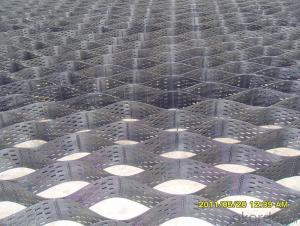

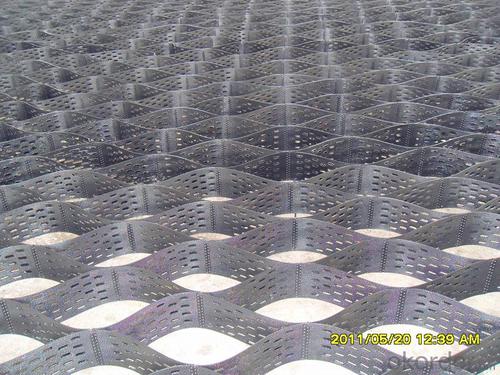

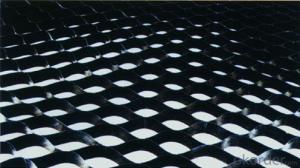

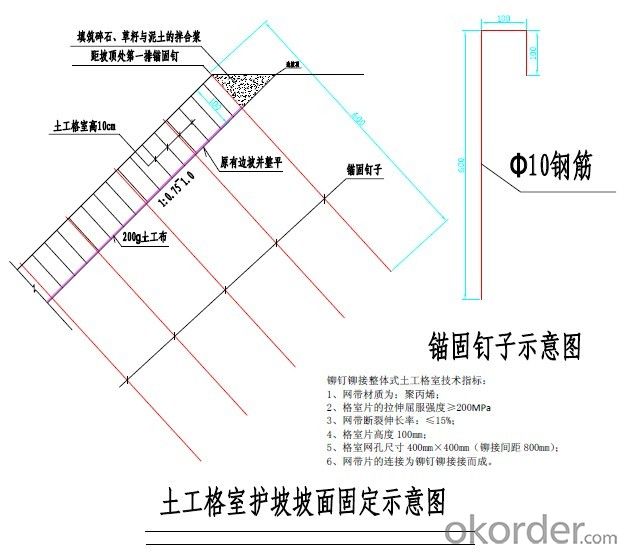

IMages of HDPE High Strength Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the long-term performance expectations for geotextile installations?

- The long-term performance expectations for geotextile installations are generally high. Geotextiles are designed to provide durable and effective solutions for various applications such as soil stabilization, erosion control, and drainage systems. With proper installation and maintenance, geotextiles can typically last for decades, providing long-lasting functionality and performance. However, specific performance expectations may vary depending on factors such as the type of geotextile, site conditions, and the intended application.

- Q: What are the key considerations for geotextile installation in corrosive environments?

- The key considerations for geotextile installation in corrosive environments include selecting a geotextile material that is resistant to corrosion, ensuring proper anchoring and fastening methods to prevent movement or damage, conducting regular inspections and maintenance to identify any signs of corrosion, and implementing appropriate protective measures such as using a geotextile with a higher corrosion resistance rating or adding a barrier layer to minimize exposure to corrosive agents.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are designed to provide strength, stability, and filtration in various applications, including landfill construction. They can be used as a reinforcement layer in landfill liners or caps to enhance the stability and prevent erosion of the waste containment system.

- Q: River slope protection geotextile unit area quality is generally how much

- Geotextile width of 2-6 meters. Length can be customized according to the requirements, generally 100g - 1000g specifications, per square meter. I am specializing in the production of geotextile materials, welcome you, hope to adopt!

- Q: How do geotextiles help with soil confinement in erosion control mats?

- Geotextiles help with soil confinement in erosion control mats by providing a stable and permeable layer that prevents soil erosion. They act as a barrier, holding the soil particles in place while allowing water to pass through, thereby reducing surface runoff and promoting root growth. This prevents the displacement of soil and helps in establishing vegetation, ultimately preventing erosion and improving soil stabilization.

- Q: Geotextile longitudinal and lateral elongation gap is too much how to adjust

- 1. The elongation at break of the geotextile is divided into longitudinal elongation at break and transverse elongation at break. Generally speaking, the elongation at longitudinal and transverse faults is not very different. GB GB / T-2008 standard requirements geotextile longitudinal and lateral elongation between 20% -100% are qualified. 2. Longitudinal transverse fracture elongation gap is too large, you can check the mixing hopper, carding machine is mixed evenly, combing evenly. 3. Acupuncture machine too fast or too high acupuncture may lead to geotextile longitudinal and transverse elongation gap, you can try to debug the speed of the next needle machine. 4. Appropriate to add some industrial oil can enhance the geotextile rupture strength, and elongation at break.

- Q: What are the different geotextile testing parameters?

- There are several different geotextile testing parameters that are used to evaluate the performance and quality of geotextiles. Some of the common parameters include tensile strength, puncture resistance, tear strength, permeability, apparent opening size, and UV resistance. These tests help determine the suitability of geotextiles for specific applications and ensure their durability and effectiveness in various geotechnical and civil engineering projects.

- Q: Neighborhoods: anti-seepage composite geotextile testing need to follow which test specifications, and routine testing items.

- (G / sq.m), film thickness (mm), mass per unit area deviation (%), breaking strength (KN / m), the product quality (GB / T-1998) (KN), the equivalent pore diameter O55 (mm), the vertical permeability coefficient (cm / s), the hydrostatic pressure (Mpa), the tearing strength (KN), the CBR breaking strength (KN) The And the front two said the basic almost, but hope that a detailed description can make you more clearly point.

- Q: Is it possible to isolate permeated geotextiles and impervious geotextiles?

- Geotextile is permeable, and water, but the soil, from the filter effect, impermeable geotextile is geomembrane composite geotextile composite products, is impermeable and waterproof, I am specializing in the production of geotechnical materials,

- Q: Waterproof geotextile in which the location of the culvert, what use

- Used in the top and side, lining the inside, mainly the role of waterproof to prevent water seepage. Huazhi geotechnical materials manufacturers need to answer for your needs

Send your message to us

Geotextil Rollo HDPE High Strength Geocell for Parking Pot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords