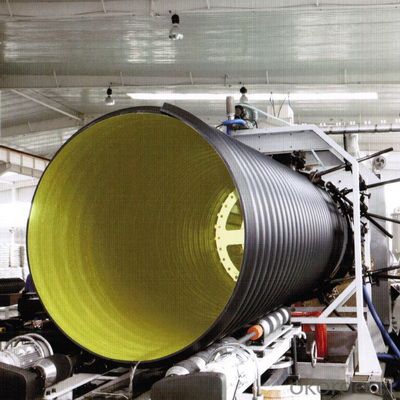

Plastic Tubes HDPE Corrugated Pipe Steel Wire Reinforced PE Pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

hdpe corrugated pipe steel wire reinforced pe pipe

1)Distinguished comprehensive performances

2)Safe and reliable ring stiffness

3)Strong load capacity to resist improper burst

4)good sealing and low cost of construction

Others features same with PE pipes

Anticorrosion, anti-ultraviolet, smooth internal surface, impact resistance, toughness, Nonpoissonous, abrasion resistance, long operating lifeas long as 50 years.

The application of hdpe corrugated pipe

1) Agricultural irrigation and water conservancy project. |

2) Industrial zone construction. |

3) Park and Golf course construction. |

4) Residential construction. |

5) Road,plot construction |

6) Power supply, the street light installment . |

7) Many situations instead of steel pipe and other pipes. |

hdpe corrugated pipe physical characters:

Items | Index | Testing Method | |

Ring stiffness. KN/m2 | SN8 | ≥8 | GB/T9647-2003 |

SN12.5 | ≥12.5 | ||

SN16 | ≥16 | ||

Impact resistance | TIR≤10% | GB/T14152 | |

Peel strength,(20°C±5°C),N/cm | ≥70 | Refer to appendix A of CJ/T225-2006 | |

Ring flexibility | No fracture and delaminating | GB/T9647 | |

Oven test | No and drying crack | Refer to 8.4.5 of CJ/T225-2006 | |

Tensile strength(N) of joints | ≥1460 | GB/T8804 | |

Creep rate,% | ≤2 | GB/T8042 | |

- Q: Can plastic tubes be used for storing chemicals?

- Yes, plastic tubes can be used for storing chemicals. However, the choice of the plastic material and its compatibility with the specific chemical being stored is crucial to ensure safety and prevent chemical reactions or degradation of the tube material.

- Q: How do plastic tubes compare to ABS tubes in terms of impact resistance?

- Plastic tubes generally have lower impact resistance compared to ABS tubes. ABS (Acrylonitrile Butadiene Styrene) is known for its exceptional impact resistance, making it a preferred choice in applications where durability and resistance to impacts are crucial.

- Q: what is dialysis tubing? how can it be used to demonstrate osmosis?

- Dialysis tubing is actually a semi-permeable membrane when used in water. Experiments illustrating osmosis and pressure gradients across a membrane use dialysis tubing. This tubing usually comes in rolls and when wet, will open up into a cylindrical tube that can be tied off at the ends. The tubing can also be fitted over a thistle tube for such experiments. Dialysis tubing is literally a semi-permeable sheet of plastic. [Like a cell membrane, it can allow certain things in, but not everything.] In a dialysis tubing experiment, one fills the inside of the sheet with a concentrated liquid of some sort and then seals off the open ends of the tube. Then, one places the tube and liquid into another type of liquid and after awhile, the liquid from the outside moves inside the tube. What I did for my first dialysis tubing experiment was filling the inside of the tube with a concentrated starch solution and placed the tubing into a beaker of Lugol's solution diluted with distilled water. After a 1/2 hr, some of the Lugol's and distilled water will have entered the dialysis tubing. One can see that osmosis has happened because the Lugol's in the tube would have turned blue when in contact with the starch. Osmosis caused the diluted/unconcentrated solution of Lugol's and dH2O to go through the semi permeable membrane and into the concentrated solution of starch. Like a cell's membrane, if the outside of the cell is more concentrated, the cell would lose water because the the water will leave the cell and go for the concentrated outside environment. If the inside of the cell was more concentrated than the outside, the outside water will go into the cell through the semipermeable membrane.

- Q: Can plastic tubes be used for storing automotive fluids?

- Yes, plastic tubes can be used for storing automotive fluids. However, it is important to ensure that the plastic material used is compatible with the specific automotive fluid being stored to prevent any chemical reactions or degradation of the tube material. Additionally, the tube should be suitable for the required pressure and temperature conditions of the fluid.

- Q: Where to find inexpensive tubes or plastic vials to fill with candy for a centerpiece?

- You could also buy a roll of tubing at Home Depot or Lowes. It comes in many different diameters, so you should be able to find just what you're looking for! Look in the plumbing aisle.

- Q: if i giv food or swith off the lights, the female would eat the eggs.HELP

- the problem with angels they learn as they go along it is normal for them to eat the eggs at first but after a few more tries they will realise not to do that. it does take a lot of time but you will get there

- Q: How can the PPR pipe be connected with the metal tube?

- The transition piece is a combination of plastic and metal, and the two materials are processed by injection molding process, and the anti leakage sealing is realized through the internal structure without adding other adhesive materials.

- Q: Are plastic tubes resistant to pressure changes?

- Yes, plastic tubes are typically resistant to pressure changes. They are designed to withstand varying levels of pressure without deforming or leaking.

- Q: i'm just curious but, is it possible to use a plastic (case) tube as an optical fiber? i was searching and found this product that i had for along time now and it is a Eyeglass Repair Kit which has a plastic tube (case). is it possible to use this as a plastic acrylic tube?

- Optical waveguides work by total internal reflection, which occurs when light attempts to exit a dense medium into a less dense one. Optical fibers are constructed with a high-index-of-refraction material coated with a material with a slightly lower index. Light striking the wall of a hollow tube will pass into the tube wall. If you metalize the inside of the tube you can get a waveguide of a sort, but it will only work over a short distance because of lossy reflection. You're not remotely close to having anything you could make into a phase conjugate mirror, unless you have discovered some amazing new optical trick.

- Q: What are the water supply plastic pipes and composite pipes?

- Belongs to the plastic water supply pipe, composite pipe with PPR pipe, PE pipe, steel plastic composite pipe, plastic pipe etc..

Send your message to us

Plastic Tubes HDPE Corrugated Pipe Steel Wire Reinforced PE Pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords