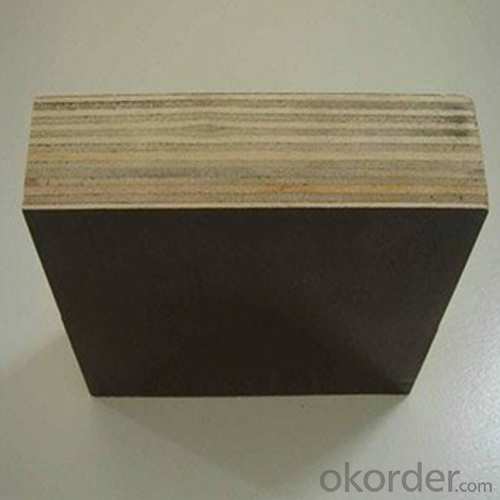

Hardwood Core Film Faced Plywood from 9-35mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: chengxin-132

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E1

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Birch

· Size: 915*1830,1220*2440,1220*2550mm

· Certification: ISO9001

· Glue: MR,WBP,MELAMINE

· Thickness: 9-35mm

Packaging & Delivery:

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by sea |

Delivery Detail: | within 15days after receiving prepay or against origin L/C |

Product Specifications:

Hardwood film faced plywood

Core: Birch, poplar and hardwood

Glue: WBP, melamine, MR

Film: Brown and black film

Size: 1220*2440mm

FILM FACED PLYWOOD with good quality and competitive price

Product | black film faced plywood and brown film faced plywood |

Face and back | Okoume, bintangor, poplar, birch pine |

Core | Poplar,hardwood or as your requests |

Thickness | 9-35mm |

Size | 1220*2440mm 1250x2500mm |

Glue | MR, WBP. MELAMINE |

color | black and brown |

Moisture | 6-14% |

Density | About 600kg/m3 |

Formaldehyde release | E0≤0.5mg/L E1≤1.5mg/L ≥E2≤5.0mg/L |

Bonding strength | ≥0.9mpa |

Packing | Inner with plastic bag, outside covered with |

Plywood at cartons, then steel tapes for strength | |

Transportation | 8plts/20GP,16plts/40GP,18plts/40HQ |

Payment | T/T L/C |

Min order | one20GP |

Delivery time | within 15days after receiving prepay or against origin L/C |

Supply ability | 60*40HQ per month |

Certificate | ISO/CE |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: The thickness of the steel plate of the temporary space sandwich panel is generally thick

- There are five and seven

- Q: I would like to buy some sandwich panels, I do not know where the quality is better?

- Aisha Yili's products are good. Quality assurance, you can 30 days unconditional return policy. And the service attitude is also very good. Style is very novel, adequate inventory. There are tens of thousands of models, the product will be weeks on the new,

- Q: Color plate and color steel sandwich panel difference?

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: What are the quality standards for color steel sandwich panels?

- Look at the weight of the foam board!

- Q: Specification for thickness of steel - wool sandwich panel

- Caigang rock wool sandwich panels are divided into roof panels and wall panels, the common specifications are 950 and 1150 type rock wool sandwich panels; but there is a manual rock wool sandwich panels, also known as manual rock wool board, This rock wool purification board common specifications are 980 and 1180,920 and 1120 and other models! Generally common rock wool sandwich panels have a thickness of 50mm rock wool sandwich panels, 75mm rock wool sandwich panels, 100mm rock wool sandwich panels, and 150mm rock wool sandwich panels. In addition, with the needs of the market, Caigang rock wool sandwich panels appeared in the new specifications model, that is, we said the polyurethane edge rock wool board, this color steel rock wool sandwich panels, high fire rating, Got the favor of the market! On the above Caigang rock wool sandwich panel solution only represents the Shandong Hongxin source steel plate color steel rock wool sandwich panel personal point of view, if more exchanges can click my picture to communicate!

- Q: Linhai 5 cm thick rock wool sandwich panels how many square

- You need the thickness of the steel plate is how much inside and outside the two steel plate, the middle is 5 cm rock wool. The thickness of the steel plate is generally 0.4mm-0.7mm color coated plate, rock wool capacity is not the same price is different, the industry generally use 80-120KG per cubic rock wool. High quality good point of the general price to ex-factory price of 85 or more.

- Q: Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Polyurethane foam can only achieve B1 flame retardant, the system's fire resistance by the two sides of the composite material fire resistance decision.

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- Normal concrete beam span of not more than 5 meters, or the volume of the beam to do very exaggerated. So use a lightweight architecture It is understood that foreign general steel truss girder, but also useful wood beams under the steel truss.

- Q: The main sheet of glass wool cotton sandwich panels

- Glass wool cotton sandwich panel panels made of colored steel plate, stainless steel plate, glass magnesium board three! The price of color steel plate is lower than that of stainless steel plate, so the price of stainless steel glass wool cotton sandwich panel is higher than that of Caigang glass wool cotton sandwich board! Double-sided color steel glass magnesium board as a panel of glass wool cotton sandwich panels need to do hand-made, so the cost of hand-woven glass wool sandwich panels is relatively high!

Send your message to us

Hardwood Core Film Faced Plywood from 9-35mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords