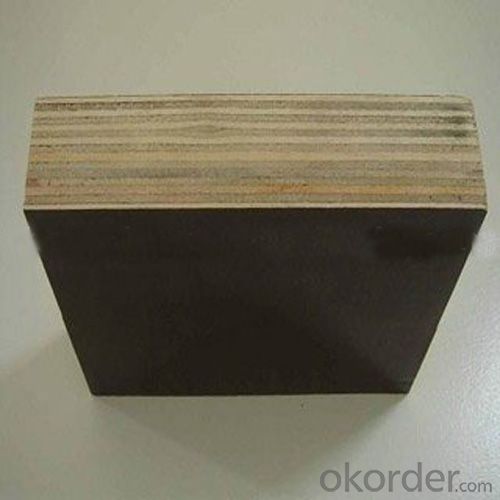

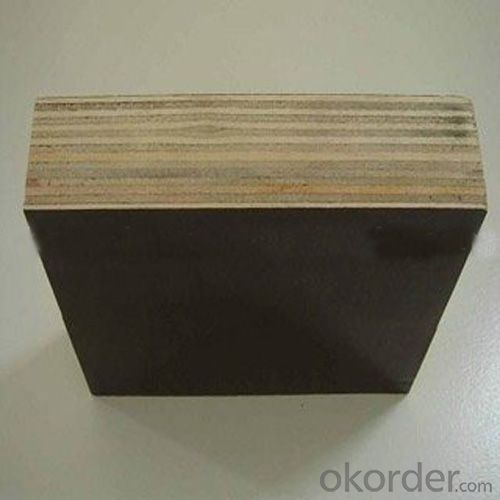

9-35mm Film Faced Plywood with Brown and Black

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E0

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Birch

· Size: 915*1830,1220*2440,1220*2550mm

· Glue: MR,WBP,MELAMINE

· Thickness: 9-35MM

· Certification: ISO9001

Packaging & Delivery

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by sea |

Delivery Detail: | within 15days after receiving prepay or against origin L/C |

Product Description:

Product | film faced plywood |

Film | black film, brown film, red film |

Core | Poplar, hardwood, birch or as your requests |

Thickness | 9-35mm |

Size | 1220*2440mm 1250x2500mm |

Glue | MR,WBP.MELAMINE |

color | black and brown |

Moisture | 6-14% |

Density | 520-720/m3 |

Formaldehyde release | E0≤0.5mg/L E1≤1.5mg/L ≥E2≤5.0mg/L |

Bonding strength | ≥0.9mpa |

Packing | Inner with plastic bag, outside covered with |

Plywood at cartons, then steel tapes for strength | |

Transportation | 8plts/20GP,16plts/40GP,18plts/40HQ |

Payment | T/T L/C |

Min order | one20GP |

Delivery time | within 15days after receiving prepay or against origin L/C |

Supply ability | 60*40HQ per month |

Certificate | CE |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Have to know the holy spring Antwerp phenolic steel sandwich board how much money a square? I heard that the insulation effect is good, fire performance is also very good

- Phenolic insulation board a square 400 or so it Almost all of the price of phenolic need 50 points of oxygen was on fire, OKorder Zhongji machinery manufacturing phenolic insulation is the export, to the domestic sales a little less, you can order the next.

- Q: What kind of support is needed

- Is the outer cover sandwich plate? With purlins and wall beams connected, purlins and wall girders connected with the steel structure, the specific you according to a steel structure of the building plans to see to know. Sandwich panels and purlins are self-tapping screws.

- Q: Polyurethane sandwich panels polystyrene sandwich panels how to identify? 75 models Price / square?

- Very good to distinguish, there is particles is polystyrene.

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q: Sandwich board machine how much money

- Metal insulation sandwich board production line, probably in the 23-30 million range, the current OKorder Changxing, Baosheng, Po day, good quality, finished product width 970,980,950 type,

- Q: So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- I would just go to the electrical panel in the basement and turn off the breaker. There should be a separate breaker for the smoke alarms. Just remember to turn them back on.

- Q: What is the difference between the board and the core board?

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than ... but generally do not choose the best! Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, ... plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement. The outermost front panel is called a panel, and the back is called a backplane. The inner board is called the core plate.

- Q: Color steel polystyrene sandwich panel specifications 0.4 * 0.3 * 50mm, of which 0.3,0.4,50 size, respectively, where the size

- Do not know what you say 0.3,0.4 unit of measurement is rice or centimeters. If it is followed by the 50 mm unit that is consistent, it basically can not say it! However, on this color steel to understand the words, 50 mm refers to the thickness. 0.4,0.3 units should be meters, so that should be 0.4 meters long, 0.3 meters wide, 0.05 meters thick polystyrene board.

Send your message to us

9-35mm Film Faced Plywood with Brown and Black

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords