Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

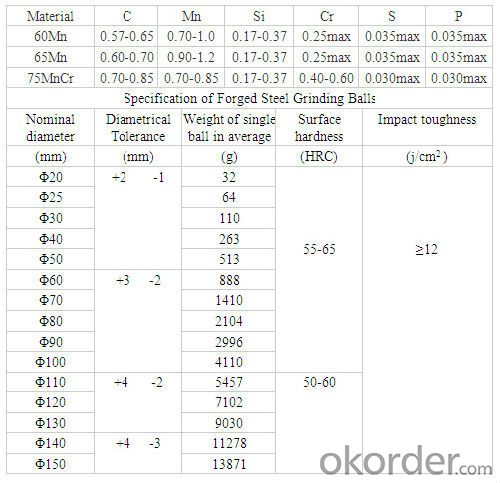

1) In general, grinding steel ball has high hardness: surface hardness to 58-65 HRC, volume hardness of 56-65 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 0.5%.

4) loss of grinding forged steel ball round rate is low.

Applied fields of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

1) Metal Mines, 2) Cement plants, 3) Water coal slurry,

4) Power stations 5) Chemical industry

Chemical Elements of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

Product and Package of Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: The casting defects of pores, trachoma how to repair?

- Airhole above 2mm recommended LT101 casting defect repair agent. If repair quality requirements, high availability LT111 iron repair agent, LT112 steel repair agent, LT113 aluminum repair agent, LT114 copper repair agent.

- Q: What is the difference between forging parts and casting parts?

- Forging is in hot state through the metal hammer or press equipment produced by forging parts. A casting is a metal that is liquid and is poured into a cavity of a specified shape and cooled and solidified. It is the forging metal soft pinch molding, and casting the metal into thin cooling solidification.Forged parts are costly and have long production cycles.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizingGenerally 0.06 mm or more

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1971 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Domestic Market, Southeast Asia, South Asia, North America, South America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Korean |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Forged Grinding Ball,Cast Grinding Ball,Casting Cylpebs,Grinding Rods,Decorative Steel Ball |

| Product Price Range | Average |

Send your message to us

Grinding Ball for Gold Mine made in Chian with Top Quality Steel as Raw Material

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords