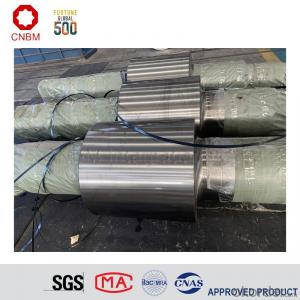

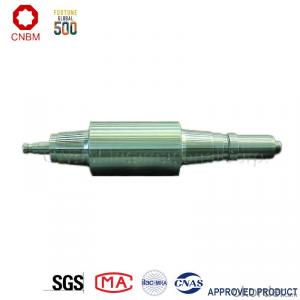

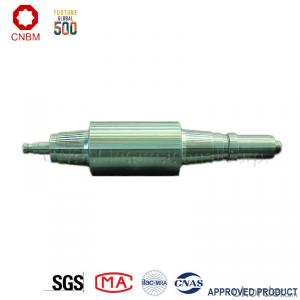

Graphitic Steel Roll With High Wear Resistance and High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM Group is integrated with four business segments: Manufacture, R&D,Sets of equipment and Logistics trading.Mill rolls are our main products.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 120 countries and regions all over the world.

The product introduction of mill roll

Equipped with advanced technological facilities on melting, casting, forging, heat treating and mechanical machining, our factory has formed 9 professional complete roll manufacturing lines of cast steel, cast iron and forged steel rolls such as strip mill rolls, heavy section mill rolls, wire & bar rolls, special shaped rolls and small-sized cold rolls and specialized production lines of bloom and slab CCM, coke oven equipments and wind power products. Annual production capacity of mill rolls is 500,000 tons, metallurgical equipment is 80,000 tons.

Workshop

Workshop is the core of our company and undertakes all of scientific research work. The company specially produces and supplies all kinds of roll used for hot strip mill, cold strip mill, plate & heavy plate mill, large-sized section mill, universal mill etc.

Products & Specification

| Mill | Application | Material | Product Specification | ||

| Hot Strip Mill | Large-sized vertical roll | Special alloy cast roll, Adamite | All Sizes | ||

| Small-sized vertical roll | Adamite, HiCr iron | ||||

| Roughing work roll | Special alloy cast steel, Adamite, HiCr steel, Semi-HSS, HiCr iron | ||||

| Finish rolling | Early stand work roll | HiCr iron, HSS | |||

| Later stand work roll | ICDP, HSS | ||||

| Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |||

| Alloy forged steel | D≤¢2000,W≤75t | ||||

| Temper rolling | Work roll | HiCr iron | All Sizes | ||

| Alloy forged steel | |||||

| Back-up roll | ICDP | ||||

| Duplex cast steel | D≤¢2000, W≤80t | ||||

| Alloy forged steel | D≤¢2000, W≤75t | ||||

| Mill | Application | Material | Product specification |

Cold strip mill & Single stand cold mill | Work roll | Alloy forged steel | All Sizes |

| Intermediate roll | Alloy forged steel | ||

| Temper roll | Alloy forged steel | ||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |

| Alloy forged steel | D≤¢2000,W≤75t | ||

Largesized universal structural mill | Break-down roll | Special alloy cast steel, alloy nodular iron | All Sizes |

| Horizontal collar | High carbon adamite (duplex) | ||

| Vertical collar | High carbon adamite, HiCr iron | ||

| Edger roll Edger roll | High carbon adamite | ||

| Shaft | Alloy forged steel |

| Mill | Application | Marterial | Product Specification | |

| CSP | Vertical Roll | Adamite, Special alloy cast steel, HiCr iron | All Sizes | |

| Roughing work roll | Semi-HSS, HiCr Steel | |||

| Finish rolling | Early stand | HiCr iron, HSS | ||

| Later stand | ICDP, HSS | |||

| Roughing & Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Steckel Mill | Vertical roll | Adamite, Special alloy cast steel | All Sizes | |

| Roughing work roll | ICDP, HiCr iron | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Plate & Heavy plate mill | Rough rolling | 2-hi work roll | Special alloy cast steel, Tool steel | All Sizes |

| 4-hi work roll | HiCr iron, ICDP | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Single stand work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

Quality Control

The company has the most advanced experimental and testing equipments in global mill roll industry, including direct-reading spectrometer, spectrum analyzer , X-ray fluorescence analyzer, scanning electronic microscope, energy disperse spectroscopy, X-ray diffractometer, image analyzer, high/low temperature metallographic microscope, X-ray stress meter, brittleness temperature tester, thermal analogue machine, dilatometer, macro and micro hardness tester, OMNISCAM-1X automatic flaw detection, USN60 ultrasonic flaw detector, magnetic powder and non-destructive flaw detection etc,. The advanced inspection equipments and experimental methods provide guarantee for quality control and experiment on material, usability test and performance.

The factories of CNBM invested 2.3 billion RMB for large-scale

CNBM international Corporation has completed equipment and technology upgrade transformation, which was concentrated on three projects, production line of centrifugal casting rolls for hot strip and plate mill, forged roll for cold/hot strip mill, national class technology center and roll material lab. Through upgrade transformation, the following targets have been achideved:

(1)It becomes the world's biggest specialized mill roll maker with the largest production scale, the most complete specifications of products and the most extensive coverage of various rolls used on rolling mill.

(2) The technology of equipments has reached international leading level.

(3) "Mechanization, automation, intellectualization, digitization" of equipments obviously improve the quality control ability.

(4) New types of research instruments improve the R&D capacity of products.

Customers Visit

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: What are the different types of testing methods used with metal casting machinery?

- Metal casting machinery commonly utilizes various testing methods to ensure the quality and integrity of casted metal products. 1. The initial and most fundamental form of testing is visual inspection. This involves visually examining the casted metal components for visible defects such as cracks, surface imperfections, or dimensional irregularities. Visual inspection is crucial in detecting any obvious flaws that may have occurred during the casting process. 2. Non-Destructive Testing (NDT) methods are employed to examine casted metal components without causing any damage or alteration to them. Some commonly used NDT methods in metal casting include: - X-ray Inspection: This method utilizes X-ray or gamma radiation to penetrate the metal and create an image that can reveal internal defects like voids or inclusions. - Ultrasonic Testing: Ultrasonic waves are used to detect defects by transmitting high-frequency sound waves through the casted metal. Any irregularities in the sound wave pattern can indicate the presence of defects. - Magnetic Particle Testing: This method involves applying magnetic particles to the metal casting's surface and then applying a magnetic field. Any defects or cracks in the metal will cause the magnetic particles to cluster, making them visible to the inspector. - Liquid Penetrant Testing: This method entails applying a liquid dye or fluorescent dye to the metal casting's surface. The dye penetrates any surface cracks or defects and is later removed. The remaining dye is examined under UV light to detect any indications of defects. 3. Mechanical Testing: This type of testing involves subjecting the casted metal components to various mechanical forces to assess their strength, hardness, and other mechanical properties. Tensile testing, hardness testing, impact testing, and fatigue testing are common mechanical tests. These tests help determine if the casted metal components meet the required specifications and standards. 4. Chemical Analysis: To determine the composition and purity of the metal used in the casting process, chemical analysis is performed. This analysis ensures that the metal meets the required specifications and possesses the desired chemical properties. Techniques like spectroscopy or X-ray fluorescence (XRF) are commonly employed for chemical analysis. By employing a combination of these testing methods, manufacturers can guarantee that metal casting machinery produces defect-free and high-quality casted metal components. These testing methods play a crucial role in identifying and rectifying any defects or irregularities, ensuring that the final products meet the necessary standards and specifications.

- Q: How can metal casting machinery contribute to waste reduction and recycling?

- There are several ways in which metal casting machinery can make a significant contribution to waste reduction and recycling. Firstly, through the use of advanced technologies and processes, these machines can help minimize material waste during the casting process itself. They are specifically designed to ensure accurate measurements and minimize errors, resulting in less scrap metal being generated. Moreover, they are capable of optimizing the utilization of raw materials by efficiently using the metal and reducing the need for excess material. Additionally, metal casting machinery enables the recycling of scrap metal. Instead of discarding leftover or excess metal, it can be collected and recycled to produce new castings. This recycling process not only reduces the amount of waste sent to landfills but also conserves energy and resources that would otherwise be required to extract and refine new metals. Furthermore, metal casting machinery facilitates the use of recycled materials in the casting process. By melting down and incorporating recycled metals into the casting material, these machines allow for the reuse of waste metal, reducing the dependence on virgin materials. This not only helps preserve natural resources but also decreases the carbon footprint associated with metal production. Moreover, metal casting machinery can contribute to the overall sustainability of the metal industry. These machines often incorporate energy-efficient technologies and processes, which in turn reduce energy consumption and greenhouse gas emissions. By adopting environmentally friendly practices, metal casting machinery helps minimize the environmental impact of the casting process. In conclusion, metal casting machinery plays a crucial role in waste reduction and recycling within the metal industry. Through efficient material usage, recycling of scrap metal, incorporation of recycled materials, and adoption of sustainable practices, these machines contribute to a more environmentally friendly and resource-efficient casting process.

- Q: What are the different types of welding operations performed on castings using metal casting machinery?

- The different types of welding operations performed on castings using metal casting machinery include gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). These welding techniques are used to join and repair castings, ensuring their structural integrity and functionality.

- Q: What are the different types of die casting used in metal casting machinery?

- There are three main types of die casting used in metal casting machinery: hot chamber die casting, cold chamber die casting, and vacuum die casting.

- Q: What are the common software programs used in metal casting machinery?

- There are several common software programs used in metal casting machinery that help optimize and streamline the casting process. One of the most commonly used programs is CAD software (Computer-Aided Design), which allows engineers to create detailed 3D models of the casting designs. CAD software helps in visualizing the final product, making modifications, and generating precise engineering drawings. Another important software used in metal casting machinery is CAM software (Computer-Aided Manufacturing). CAM software takes the 3D models created in CAD software and converts them into machine-readable instructions. It determines the tool paths, cutting speeds, and feeds required for the casting process, ensuring accuracy and efficiency. Simulation software is also widely used in the metal casting industry. This software allows for virtual testing and analysis of the casting process before it is actually implemented. It helps identify potential defects, optimize the casting parameters, and predict the behavior of the molten metal, ultimately improving the final casting quality. Furthermore, there are quality control software programs that monitor and analyze data collected during the casting process. These programs help identify any deviations or defects in real-time, ensuring that the casting meets the required specifications and standards. Additionally, there are various ERP (Enterprise Resource Planning) software systems used in the metal casting industry. These programs help manage the entire casting process, from material procurement to scheduling, inventory management, and order tracking. They provide a centralized platform for efficient resource allocation, communication, and coordination between different departments involved in the casting operations. Overall, the common software programs used in metal casting machinery play a crucial role in enhancing productivity, accuracy, and quality control in the casting process. They enable efficient design, precise manufacturing instructions, virtual testing, quality assurance, and streamlined management of the overall casting operations.

- Q: What are the different types of filters used with metal casting machinery?

- To ensure the quality of the final castings, various filters are utilized with metal casting machinery. These filters serve the purpose of eliminating impurities and solid particles from the molten metal, resulting in castings that are cleaner and more precise. Ceramic filters, which possess exceptional thermal stability and high mechanical strength, find extensive use in metal casting. They are crafted from ceramic materials like silicon carbide or alumina, which can endure the elevated temperatures of molten metal. By removing impurities such as slag, sand, and oxides, these filters enhance the quality of the castings. Foam filters, on the other hand, are produced from a porous ceramic material with a sponge-like structure. They are particularly effective in filtering non-ferrous metals like aluminum. Due to their high specific surface area, they can efficiently capture impurities and solid particles. Additionally, these filters exhibit excellent resistance to thermal shocks, making them suitable for applications involving high temperatures. Sand filters, also known as foundry sand, are commonly employed in metal casting processes. Composed of fine-grained sand with a specific grain size distribution, they are utilized to eliminate large particles and impurities from the molten metal. Positioned in the pouring basin or gating system, these filters purify the metal as it flows into the mold. Mesh filters, made from a fine metal wire mesh, are typically utilized for filtering non-ferrous metals such as copper, bronze, or brass. By effectively eliminating oxide films, sand, and other impurities, they contribute to the purification of the molten metal. The size of the mesh can be adjusted according to the desired level of filtration. Lastly, ceramic foam filters combine the attributes of both ceramic and foam filters. They consist of a ceramic foam structure coated with a thin layer of ceramic material. These filters offer efficient filtration and improved flow control, making them commonly used in both ferrous and non-ferrous metal casting. In summary, metal casting machinery employs various types of filters, including ceramic filters, foam filters, sand filters, mesh filters, and ceramic foam filters. Each type possesses distinct advantages and is selected based on the specific requirements of the casting process and the type of metal being cast. These filters play a vital role in guaranteeing the quality and integrity of the final castings.

- Q: How are cores positioned and supported in metal casting machinery?

- To ensure stability and accuracy during the casting process in metal casting machinery, various techniques are employed to position and support cores. Cores, typically made of sand or other materials, are utilized to create cavities or intricate shapes within the final casting. One commonly employed method for positioning cores involves the use of core prints or core seats. These recessed areas or projections on the mold or pattern aid in locating and supporting the cores. By providing a precise fit for the cores, the core prints securely hold them in place during the pouring of molten metal. In addition to core prints, core pins or dowels can be utilized to support the cores. These cylindrical rods are inserted into both the core and the mold or pattern. The presence of core pins offers additional support, preventing any shifting or movement of the core during the casting process. Another technique used to provide support to cores is the utilization of chaplets or chaplet wires. These small metal supports are positioned between the core and the mold, securing the core in place. Typically made of a material that melts or disintegrates during casting, chaplets allow for easy removal of the core after solidification. Moreover, supports such as core rods, core plates, or core boxes are employed to stabilize and position large or complex cores. These supports ensure that the cores maintain their shape and position throughout the casting process. Overall, the proper positioning and support of cores in metal casting machinery are vital to guarantee the integrity and quality of the final castings. Manufacturers can achieve accurate and precise casting results by utilizing a combination of techniques such as core prints, core pins, chaplets, and supports.

- Q: How does metal casting machinery handle the removal of finishes from castings?

- Metal casting machinery typically handles the removal of finishes from castings through a process called shot blasting. Shot blasting involves using high-speed projectiles, such as steel shot or grit, to forcefully propel against the surface of the casting. The projectiles impact the casting's surface, effectively removing any finishes, coatings, or impurities present. The shot blasting process starts with loading the castings onto a conveyor belt or into a shot blasting chamber. As the castings move through the machine, they are subjected to a stream of projectiles propelled by centrifugal force or compressed air. These projectiles strike the castings at high velocity, dislodging any unwanted finishes or coatings. The type of shot blasting machinery used can vary depending on the size and complexity of the castings. For smaller castings, a tumble blast machine may be employed, where the castings are tumbled inside a rotating drum while shot is continuously blasted onto them. On the other hand, larger castings may require a more specialized shot blasting machine, such as a spinner hanger or a conveyor blast machine, which can handle heavier and bulkier parts. After the shot blasting process, the castings are thoroughly cleaned and free from any finishes or coatings that were previously applied. This prepares the castings for further processing, such as heat treatment, machining, or surface finishing operations. Overall, metal casting machinery effectively handles the removal of finishes from castings through the shot blasting process. It provides an efficient and reliable method to ensure that castings are clean and ready for subsequent manufacturing operations.

- Q: What are the different types of weight and density inspection methods used in metal casting machinery?

- There are several types of weight and density inspection methods commonly used in metal casting machinery. These methods are employed to ensure that the final castings meet the required weight and density specifications. One common method is the use of weighing scales. Castings are placed on a weighing scale to determine their weight. This is a simple and straightforward method that provides an accurate measurement of the weight of the casting. Another method is the use of displacement measurement. This involves measuring the volume of the casting by immersing it in a liquid and measuring the amount of liquid displaced. The density of the casting can then be calculated by dividing the weight of the casting by its volume. Density can also be measured using X-ray or gamma-ray techniques. These methods involve passing X-rays or gamma rays through the casting and measuring the amount of radiation that is absorbed. The absorption of radiation is directly related to the density of the casting. Ultrasonic testing is another commonly used method for weight and density inspection. This method involves sending high-frequency sound waves through the casting and measuring the time it takes for the waves to bounce back. The density of the casting can be determined by analyzing the speed of the sound waves. Additionally, visual inspection techniques are often employed to check for any visible defects or irregularities in the casting. These can include cracks, voids, or other imperfections that could affect the weight and density of the casting. Overall, the combination of these different weight and density inspection methods ensures that the castings produced by metal casting machinery meet the required weight and density specifications, resulting in high-quality and reliable products.

- Q: How long does metal casting machinery last?

- The lifespan of metal casting machinery can vary depending on several factors. Generally, well-maintained machinery can last for several decades without major issues. However, it is important to note that the longevity of metal casting machinery also depends on the type of machinery, frequency and intensity of use, quality of maintenance, and technological advancements. In the case of traditional sand casting machines, which are often made of durable materials like cast iron or steel, they can easily last for 20 to 30 years or even longer with proper care. These machines are designed to withstand the high temperatures and pressures involved in the metal casting process. On the other hand, more modern and technologically advanced machinery, such as die casting or investment casting machines, may have a shorter lifespan due to the complexity of their components and the wear and tear they undergo during operation. These machines may require more frequent maintenance and parts replacement to ensure optimal performance, which can affect their overall lifespan. Furthermore, advancements in technology and industry standards can render older machinery obsolete over time. As new techniques and equipment are developed, older machinery may become less efficient or unable to meet the growing demands of the industry. This can lead to the need for machinery upgrades or replacements. Ultimately, the lifespan of metal casting machinery can vary greatly depending on various factors. Regular maintenance, proper usage, and keeping up-to-date with technological advancements can significantly extend the lifespan of these machines, ensuring efficient and reliable operations for many years.

Send your message to us

Graphitic Steel Roll With High Wear Resistance and High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches