Graphite electrode uhp 600 for EAF in steel industry and stainless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin:

Hebei, China

Brand Name:

JINSH

Model Number:

UHP 600mm

Type:

Electrode Bolt

Application:

eaf

Length:

1600-2700

Grade:

UHP (Ultra High Power)

Resistance (μΩ.m):

5.5Ω

Apparent Density (g/cm³ ):

1.68

Thermal Expansion:

1.5

Flexural Strength (N/㎡):

11Mpa

Packaging & Delivery

Packaging Details

Wooden box and tray packaging, should be fixed by steel belt

Port: TIANJIN

Lead Time :

Quantity(Tons) 1 - 100 101 - 500 501 - 2000 >2000 Est. Time(days) 7 15 15 To be negotiated

Product discription

| Graphite electrode uhp 600 for EAF | |

Resistance | 5.5 |

| μ Ω.m(Max) | |

Density | 1.68 |

| g/cm³(min) | |

Flexure Strength | 11 |

Young's Modulus | 14 |

| Gpa(Max) | |

Ash Content | 0.2 |

| %(Max) | |

CTE(100-600℃) | 1.5 |

| 100-6/℃(Max) | |

Application

Graphite electrodes are widely used for production of alloy steels, metal and other nonmetallic materials, etc.

* DC electric arc furnace.

* AC electric arc furnace.

* Submerged arc furnace.

* Ladle furnace.

Size information

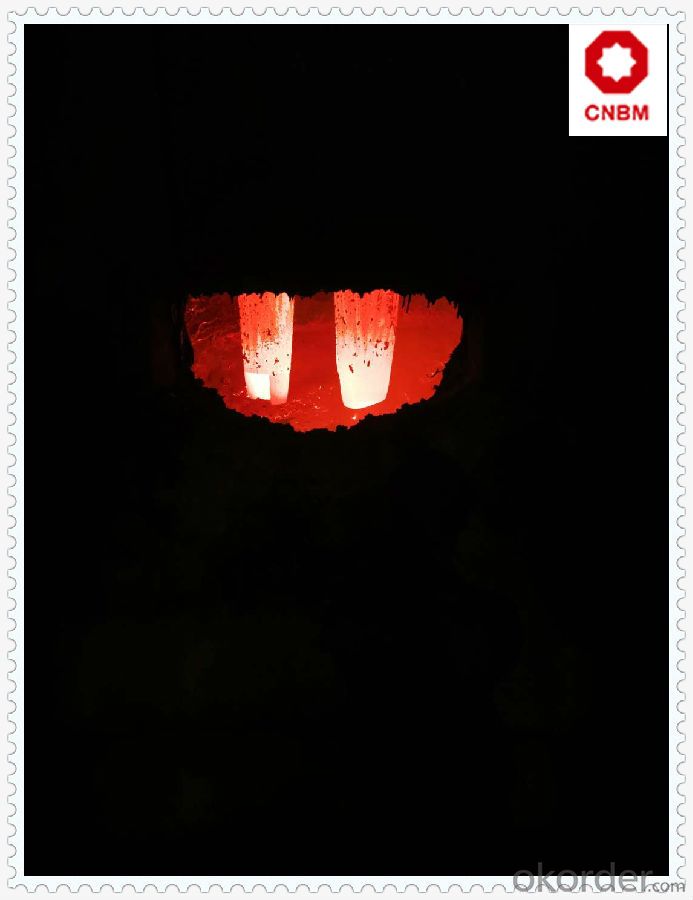

Detailed Images

- Q: Is graphite electrode good for foreign trade?

- Foreign sales commission depends on the price you talk to the customer, and the profit is objective.

- Q: Where is the graphite electrode scrap?

- Finally, a bright white Ar-ICP discharge is formed, especially like a drop of water droplets.

- Q: The future of graphene

- A report released recently pointed out that the Chinese Academy of Sciences, graphene research and industrialization continues to heat up, from the distribution of graphene patents in the field, including the application of technology research hot spots: layout of graphene as a electrode material of lithium ion batteries, solar battery electrode materials, thin film transistor preparation, sensor, semiconductor device, composite material preparation of transparent, touch screen display, transparent electrode

- Q: Electrolytic salt water why use iron as a cathode, all with graphite can not?

- The iron electrode is easier to be installed in the electrolytic cell, which is more convenient than the graphite electrode, and the density of the graphite is small. After being adsorbed by hydrogen, the graphite is easy to float up, and the density of the iron is larger. This problem does not exist in the.5

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Not alwaysIt depends on the rate of electrolyzed water or the rate at which sodium sulfite is oxidized.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- External electronic wire and the directional movement of ions in the solution of the directional movement between the poles of a closed loop, so that the two electrode reaction, electron transfer process, ordered a current converting chemical energy to electrical energy.Attention, here, "the ion does not go ashore, the electron does not enter the water"." That is the external circuit of graphite electrode is composed of electron flow and electrolyte ion flow; graphite electrode is to produce voltage and electrolyte, and to provide or absorb electrons

- Q: Why should graphite paper be placed between the heater and the graphite electrode?

- Heater design, the common heater has three shapes, cylinder, cup, spiral, the vast majority of the current heater is cylindrical, as shown in figure. The spiral heater has complicated processing technology and has been eliminated. Cup shaped heater for hemispherical crucible, the bottom melt temperature is more uniform, because the processing technology is difficult, already no use. Nowadays, most of them use cylinder heaters. The cylindrical heater is not only easy to process, but also is related to the large number of flat crucible used in the direct drawing single crystal furnace.

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- In addition, the infiltration of water on graphite is not good, can not get the effect of dust removal. Now there are special graphite machine, sealing system. Air-cooled can be used, after all, the best air-cooled.

- Q: What are the losses in graphite electrode?

- In what environment is the loss, friction, or in the case of high temperature, high temperature will be oxidized, and if in the case of friction, you can first use more wear-resistant graphite material. So please ask this question clearly, and then answer you, thank you.

- Q: Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- Graphite as anode, generally do not need special treatment, but to choose high purity, high density, high strength (so-called "three high" graphite) graphite on the line, this graphite in brush plating operations are often used as anode material.

Send your message to us

Graphite electrode uhp 600 for EAF in steel industry and stainless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches