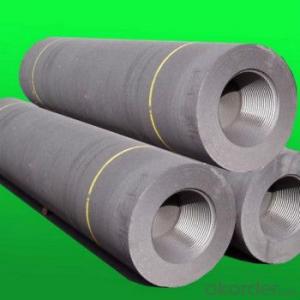

Graphite Electrode Manufacturer's Hot Sale UHP 600mm Graphite Electrode for Steeling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

China Manufactured Graphite Electrode

Graphite electrode is made from the domestic petroleum coke as well as high quality needle coke which are widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials

Other related properties include: Graphite / Steel Welding Electrode

Graphite / Steel welding electrode belongs to carbon steel electrode, which is commonly used for automobile bodies, ornamental iron, metal furniture, truck frames and bodies, farm implementations, machinery guards and storage tanks.

Main Product Features:

· Stable arc

· More resistant to splatter and smoke inhalation.

· Higher deposition efficiency

· Excellent welding performance

· Easy restrike.

Our welding electrodes have more resistance to splash and smoke, easy restart weld quality design also including resistances to dust and smoke.

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, HP, UHP

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: Electrolytic salt water why use iron as a cathode, all with graphite can not?

- When electrolyzed salt water is used, the cations in the solution (H+, ionized by H2O) are moved to the cathode by the electric field force, and electrons are generated at the cathode to produce H2 hydrogen, and the hydrogen H2 generated does not react with iron

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For operators, copper is certainly better, graphite will have dust, the human body has serious harm

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- If it is molten, it can be made out of silverFor solution, only AgNO3+H2O== electrolysis ==Ag+HNO3+O2 is analyzedWhen the HNO3 concentration is enough, it will continue to react with Ag.... So you can't get Ag elements.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Instead of copper as discharge material.1. Electrode design1 can reduce the number of individual electrodes / can be made into a composite electrode2, it can save the electrode clamp system and save the cost2, the electrode processing1, high speed milling rough processing copper block 3 times2, high-speed milling finishing faster than copper 5 times3. Good machinability4, complex geometric modeling can be realized3, light weight, its density is less than 1/4 of copper1, good thermal stability (without deformation)2 can reduce the number of individual electrodes / can be made into a composite electrode3, without deburring4. The electrode is easy to clamp4 、 electric discharge machining EDM1, roughing, the electrode loss is small2, high work removal rate3 can reduce the number of individual electrodes / can be made into a composite electrode4. No pollution to the environment in the electrolyte5, light weight, its density is less than 1/4 of copper6, excellent thermal stability, the electrode does not change7, the fine graphite electrode can be used to produce high quality workpiece surfaceDifferent grades of graphite materials can be used for processing different workpieces

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- In the electric arc furnace, the electric energy is released in the form of an arc, and the conductor is heated and melted. According to the quality index, the conductor can be divided into ordinary power, high power and ultra high power.

- Q: How much does a graphite electrode cost about a ton?

- And different sizes of prices also change, you simply say you use the environment, that is used in where? And how to use it to tell you the price

- Q: Graphite graphite graphite graphite electrode what is the use?

- The graphite electrode can be divided into artificial graphite electrode and natural graphite, artificial graphite electrode is the main raw material of petroleum coke and pitch coke, made after graphitization process of the natural graphite electrode is better than that of artificial graphite electrode, and does not require the graphitization process is complex, it can save energy, therefore, natural graphite electrode the rapid development in recent years.

- Q: How do graphitized electrodes differentiate between high power and low power?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

Send your message to us

Graphite Electrode Manufacturer's Hot Sale UHP 600mm Graphite Electrode for Steeling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches