Graphite Electrode Price Per Ton for Arc Furnace by Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

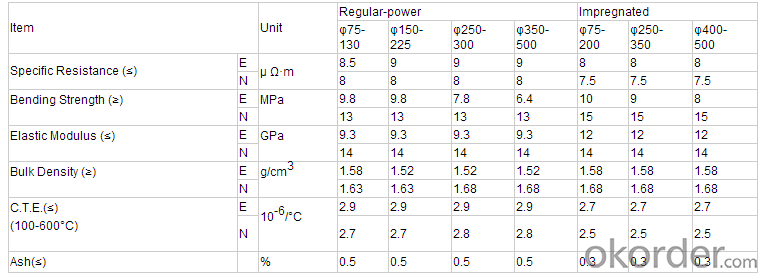

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Why should supercapacitors use graphite as electrode material?

- Because graphite material processing speed is fast, the cost is low.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The graphite part is called pyrolytic graphite. Stronger than ordinary graphite, strong oxidation resistance.

- Q: Which department in the steel plant needs graphite in large quantities?

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: The difference between graphite electrode and graphite rod

- The difference between an electrode and a rod is that the electrode has a lead conductor, and the rod is not.

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- Graphite electrode should be relatively pure, composed of graphite.

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- After calcined to eliminate ash and volatile part of the points in this process will be a lot of weight loss, in the process of crushing mixing in process of baking or graphite in high temperature heat treatment, another part of the impurities were excluded, so the raw material is higher than the rate of finished products.

- Q: Graphite electrode press device

- Ultra high power graphite electrodes. Use of graphite electrodes with a current density greater than 25A / cm 2. Used primarily in ultra high power arc furnaces

- Q: What do carbon products include?

- Carbon and graphite materials are mainly carbon based non-metallic solid materials, in which carbon material is basically composed of non graphitic carbon material, and graphite material is basically composed of graphite carbon material. For the sake of simplicity, carbon and graphite materials are sometimes referred to as carbon materials (or carbon materials).

- Q: What about graphite electrodes for steel mills?

- Hebei North graphite electrode factory produces various specifications of graphite electrode, with low resistance, high density, small ash, and so on, so that less tons of steel-making, quality is good

- Q: I remember the more lively metal, the electron?

- C is a salt solution of copper metal because copper is first reduced to a single element on a graphite electrode.Moreover, the addition of dilute sulfuric acid has a H2 emission, then a H of the previous metal.

Send your message to us

Graphite Electrode Price Per Ton for Arc Furnace by Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords