Graphite Electrode Cost - HP-D.300mm-L.1800mm with Nipple

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

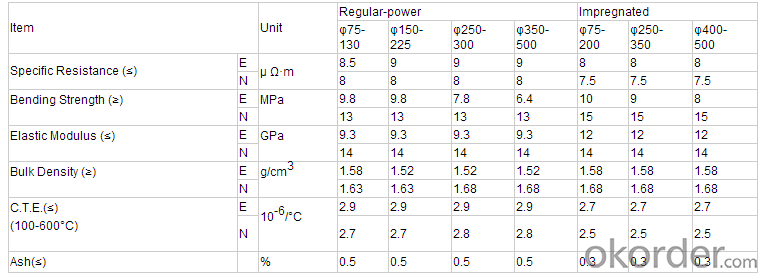

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: Graphite electrode in milling machine processing, dust is especially big, boot 5 minutes, workshop can not open the figure, what is the solution?

- Because will cause a short circuit, the best selection of bag type dust collector, our company is graphite in Linzhou, and before you like, then Xinxiang Keli machinery to help us to design a set of dust removal equipment, and then the operation almost no dust, you can consult the specific

- Q: Specification for graphite electrodes commonly used in steel works

- General specification for graphite electrode diameter Phi 300 Phi 500mm, Phi Phi 550 - the current usage of 800mm graphite electrodes is also great, the graphite electrode length was between 1600 and 2700mm.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- Ultra high power graphite electrode. A graphite electrode that allows current densities greater than 25A/ cm 2 is allowed. Mainly used in ultra high power steelmaking arc furnace

- Q: How long is the graphite electrode machining cycle?

- Industrial graphite is hard and brittle, and the tool is worn more seriously during machining. It is generally recommended to use carbide or diamond coated cutting tools. When the graphite is rough, the cutter can be directly worked on the workpiece. When it is finished, it is necessary to use light knife to walk quickly to avoid the occurrence of chipping and chipping

- Q: The difference between graphite electrode and graphite rod

- The difference between an electrode and a rod is that the electrode has a lead conductor, and the rod is not.

- Q: Electrolytic water solution, two electrodes are graphite electrode, the negative electrode can produce large amounts of hydrogen, the anode does not produce half of oxygen, and only a small amount of it?

- The oxygen will react with the graphite and the gas will dissolve.The iron has been oxidized.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Instead of copper as discharge material.1. Electrode design1 can reduce the number of individual electrodes / can be made into a composite electrode2, it can save the electrode clamp system and save the cost2, the electrode processing1, high speed milling rough processing copper block 3 times2, high-speed milling finishing faster than copper 5 times3. Good machinability4, complex geometric modeling can be realized3, light weight, its density is less than 1/4 of copper1, good thermal stability (without deformation)2 can reduce the number of individual electrodes / can be made into a composite electrode3, without deburring4. The electrode is easy to clamp4 、 electric discharge machining EDM1, roughing, the electrode loss is small2, high work removal rate3 can reduce the number of individual electrodes / can be made into a composite electrode4. No pollution to the environment in the electrolyte5, light weight, its density is less than 1/4 of copper6, excellent thermal stability, the electrode does not change7, the fine graphite electrode can be used to produce high quality workpiece surfaceDifferent grades of graphite materials can be used for processing different workpieces

- Q: What is the composition of petroleum coke and what is its use?

- Medium sulphur and common cooked coke; used in large quantities for aluminium smelting. High sulfur, ordinary coke is used in chemical production, such as the manufacture of calcium carbide, silicon carbide, etc., but also as a metal casting and other fuels. Most of the petroleum coke produced in China belongs to low sulfur coke, which is mainly used for smelting aluminium and making graphite.

Send your message to us

Graphite Electrode Cost - HP-D.300mm-L.1800mm with Nipple

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords