Graphite Electrode Applications - Graphite Electrode with Nipple Price-HZ -400M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

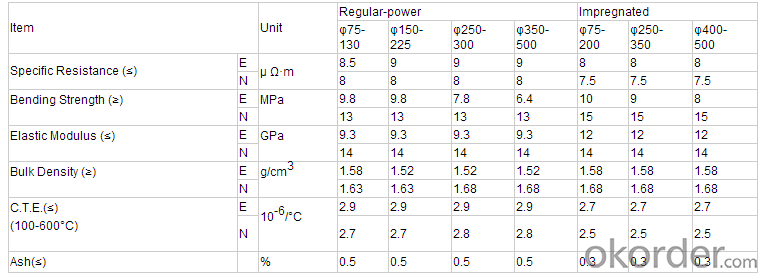

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Why should supercapacitors use graphite as electrode material?

- Because the graphite material's electrochemical stability is good, can let the super capacitor withstand the higher monomer voltage. The electrode is not easy to wear out.

- Q: Thermal expansion coefficient of graphite

- Thermal expansion coefficient (100 degrees Celsius --600 degrees Celsius) diameter 200--500 graphite electrode body is not greater than 2.410 of the negative four times per degree Celsius

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- Because the carbon containing ash, a graphite resistor 2-3 times, so the use of graphite electrode is better.

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- The key is you use and what type of need, say, abroad, what Dongyang, sigley are good, but also, very expensive, you can also choose to try our home

- Q: Specification for graphite electrodes commonly used in steel works

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: Synthesis techniques of carbon nanotubes

- Catalytic pyrolysis is one of the widely used methods for preparing carbon nanotubes. The method mainly uses transition metal as catalyst, and is suitable for large-scale preparation of carbon nanotubes. The content of carbon nanotubes in the products is higher, but the defects of carbon nanotubes are more.

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- 1. graphite (two kinds of EDM3 and EDM200)2. copperIn general, graphite electrode for extensive escape material (graphite texture loose, discharge energy is relatively large, removal of materials faster, but face flowers that roughness is relatively large

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- If you are through the material can also be screened and then sold, usually 1-5 of the particle size, fine powder can only add adhesive column

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- The graphite powder is soft, black and gray, greasy and polluting paper. Hardness is 1~2, along the vertical direction with the increase of impurities, its hardness can be increased to 3~5. The specific gravity is 1.9 ~ 2.3. Under isolated oxygen conditions, the melting point is above 3000 degrees Celsius and is one of the most refractory minerals. At room temperature, the chemical properties of stone toner are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents. The material has high temperature resistance and conductivity, and can be used as refractory materials, conductive materials, wear-resistant and lubricating materials.

Send your message to us

Graphite Electrode Applications - Graphite Electrode with Nipple Price-HZ -400M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords