Graphite Electrode with Nipple Price -Hp-D.300mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

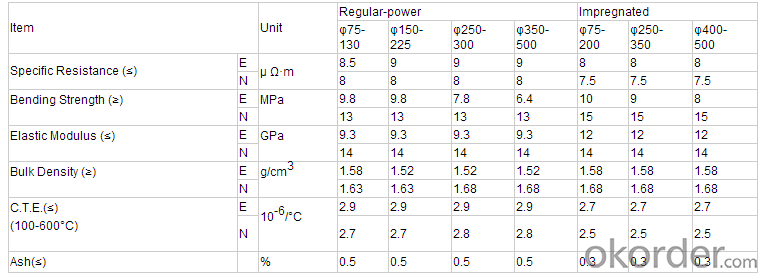

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Use of graphite in steelmaking

- At present in the world (MgO-C brick raw material for graphite and magnesium) as refractory material, has been widely used in steelmaking, has become a traditional use of graphite.

- Q: Why should the carbon brush for the trolley be made of graphite?

- Graphite has good conductivity

- Q: Is graphite flammable?Why do I bake pencil cores with a fever that doesn't burn?

- The temperature is not enough, the composition of graphite is carbon, of course, flammable, but each kind of object burning point is not the same, the nature of graphite is relatively stable, burning point is very high, cigarette lighter this temperature is certainly not burning up.Useful words, remember to adopt Oh, thank you ~!

- Q: Synthesis techniques of carbon nanotubes

- The synthesis techniques of carbon nanotubes are mainly arc method, laser ablation (Zheng Fa) method, catalytic cracking or catalytic chemical vapor deposition (CCVD), and directional control growth method based on various synthesis techniques.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- The popularization and use of this technology can bring about such economic and social effects: (1) the consumption of graphite electrode units is less, and the production cost is reduced. For example, a steel plant, according to the annual production level did not occur in LF refining furnace 35 week graphite electrode, refining furnace 165 consumption calculation, using anti oxidation technology of graphite electrode, graphite electrode can save 373 per year(153 tons) electrode, each year ultra high power electrode 16900 yuan computation, can save 2 million 585 thousand and 700 yuan rmb.

- Q: What are the factors that affect the electrode wear rate of machine tools?

- Effect of processing voltage on electrode wear. The processing voltage is the average voltage between the discharge time and the gap. When the voltage is lower than the power supply voltage (voltage) 25%, electrode loss will increase, which is due to the electrode and the workpiece is too close, the discharge column energy is too large, the electrodes generate heat radiation is too strong, at the same time, there are a large number of continuous arc discharge. But the working voltage is too high (partial load processing), bad conditions of thermal effect in the gap, is not conducive to the adsorption of copper electrode of carbon graphite, destroy the covering effect. Similarly, the electrode loss increase, therefore, corresponding to different processing standards should be selected to adjust the discharging gap voltage.

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- The graphite powder is soft, black and gray, greasy and polluting paper. Hardness is 1~2, along the vertical direction with the increase of impurities, its hardness can be increased to 3~5. The specific gravity is 1.9 ~ 2.3. Under isolated oxygen conditions, the melting point is above 3000 degrees Celsius and is one of the most refractory minerals. At room temperature, the chemical properties of stone toner are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents. The material has high temperature resistance and conductivity, and can be used as refractory materials, conductive materials, wear-resistant and lubricating materials.

- Q: Excuse me, why does the graphite electrode flake when electrolyzed salt water is used?

- Aqueous solution electrolytic cell has no diaphragm and diaphragm. Two kinds of commonly used diaphragm electrolyzer. In chlorate production and mercury method to produce chlorine and caustic soda, with no diaphragm electrolyzer. Try to increase the surface area per unit volume, can improve the production strength of electrolytic cell. Therefore, the modern electrode diaphragm electrolyzer the vertical components due to internal electrolysis. The material and structure and installation of different performance and different characteristics.

- Q: Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages

Send your message to us

Graphite Electrode with Nipple Price -Hp-D.300mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords