Gpc1430h41 Prepainted Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

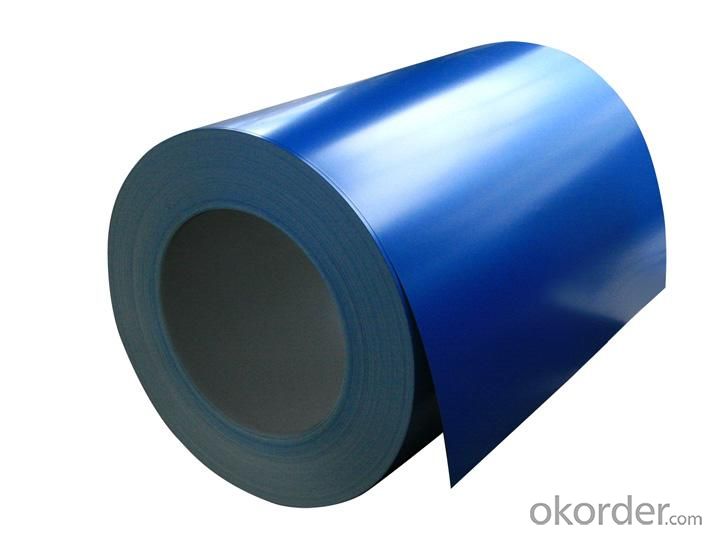

1.Structure of AA1060 Prepainted Aluminium Coils Used for Construction Description

AA1060 Prepainted Aluminium Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1060 Prepainted Aluminium Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1060 Prepainted Aluminium Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA1060 Prepainted Aluminium Coils Used for Construction Images

4.AA1060 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA1060 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a high-quality aluminum coil, consider the following factors: purity level, which should be 99.5% or higher for most applications; surface finish, ensuring it's smooth and free from defects; thickness consistency, which should be uniform across the entire coil; mechanical properties, such as tensile strength and elongation, that meet industry standards; and adherence to specific alloy grades for particular applications. Additionally, check for certifications from recognized standards organizations and consider the supplier's reputation for quality and consistency.</p>

- Q: remember maybe a decade ago or so, copper used to be cheaper than aluminum. now it is the other way around, copper is more expensive. Even copper pennies cost more so I heard they are mixed with another metal to make a penny. What caused the change in value and when did it really start happening?In fact, copper has become valuble enough to steal. Some factories which have copper, have had their metals stolen, but outsiders who break into the factories to specifically take the copper. Then the factories started hiring security to prevent intruders from taking the copper.

- The two metals are a long way apart on the electro-chemical scale. This means that if they come into contact, a small - but significant - voltage will exist between them - completely independent of what currents are actually in the wires. This small voltage causes corrosion of both metals: not good!

- Q: Hi, I have a large bag of aluminium sulfate that I would like to use to turn my hydrangeas blue but there are no instructions on the pack, can anyone tell me how much I need (mixed with water)

- I usually sprinkle about 1/4 cup around the base of the plant and water it in. This must be done before flowers appear.

- Q: How are aluminum coils used in electrical applications?

- Due to their advantageous properties, aluminum coils find wide application in various electrical uses. Transformers, motors, and inductors are the primary domains where these coils are employed. Transformers utilize aluminum coils to facilitate the transfer of electrical energy from one circuit to another. These coils are wrapped around a magnetic core, thereby facilitating efficient energy transfer. Aluminum coils are preferred over copper coils in transformers due to their affordability, light weight, and superior conductivity. Moreover, aluminum coils exhibit higher thermal conductivity, enabling better heat dissipation. This feature is crucial for maintaining transformer efficiency and longevity. In motors, aluminum coils serve as the winding material for the stator, which is the stationary component of the motor. By passing an electrical current through the coils, a magnetic field is generated. This magnetic field interacts with the rotating magnetic field produced by the motor's rotor, resulting in motor rotation. Aluminum coils are favored in motors due to their lightweight nature, contributing to overall motor efficiency by reducing its weight. Inductors, another electrical component, employ aluminum coils. Inductors store electrical energy in the form of a magnetic field. When an electric current traverses the coil, a magnetic field is generated, which opposes changes in the current. Aluminum coils are utilized in inductors owing to their high electrical conductivity, facilitating efficient energy storage and release. In summary, aluminum coils are extensively used in electrical applications due to their cost-effectiveness, lightweight nature, excellent conductivity, and high thermal conductivity. Their application in transformers, motors, and inductors plays a pivotal role in ensuring efficient and reliable operation of electrical systems.

- Q: What are the different surface treatments available for aluminum coils?

- There are several surface treatments available for aluminum coils, each with its own benefits and applications. Some of the common surface treatments include: 1. Mill Finish: This is the standard untreated surface of aluminum coils. It has a dull appearance and is suitable for applications where aesthetics are not a priority, such as industrial or structural uses. 2. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum coils. This treatment enhances the corrosion resistance, durability, and appearance of the coils. Anodized aluminum coils are commonly used in architectural applications, such as building exteriors or window frames. 3. Paint Coating: Aluminum coils can be coated with various paints to improve their appearance, protect against corrosion, and provide additional functionality such as heat reflection or insulation. Paint coatings can be applied in different thicknesses and finishes, ranging from standard coatings for general use to specialized coatings for specific applications like automotive or aerospace industries. 4. Brushed Finish: This treatment involves brushing the surface of aluminum coils with abrasive materials to create a textured finish. Brushed aluminum coils have a distinct pattern and are often used in decorative applications, interior design, or signage. 5. Embossed Finish: Aluminum coils can be embossed with patterns or textures to enhance their appearance or improve their functionality. The embossing process alters the surface of the coils, creating a raised or recessed design. Embossed aluminum coils are commonly used in architectural, automotive, or packaging applications. 6. Laminating: Aluminum coils can be laminated with various materials, such as films or foils, to provide additional protection, insulation, or decorative effects. This treatment can enhance the appearance, durability, or functionality of the coils, depending on the type of laminating material used. These are just a few examples of the surface treatments available for aluminum coils. The choice of treatment depends on the specific requirements of the application, such as aesthetics, corrosion resistance, durability, or functionality. It is important to select the appropriate surface treatment to ensure the desired performance and longevity of the aluminum coils in their intended use.

- Q: The user is asking if it's possible to use an electric welder for joining aluminum coils.

- <p>Yes, you can use an electric welder to weld aluminum coils together. However, it's important to use the correct type of welder and settings. Gas tungsten arc welding (GTAW), also known as TIG welding, is commonly used for aluminum due to its precision and ability to control heat input. MIG (Metal Inert Gas) welding can also be used for thicker aluminum materials. Ensure you use the right filler material, a suitable welding current, and proper shielding gas to prevent oxidation. Always follow safety precautions and consult with a professional if you're unsure about the welding process.</p>

- Q: This question asks about the impact of aluminum coils on safety and health protection during welding processes.

- <p>Aluminum coils can significantly affect welding safety and health protection due to their unique properties. Aluminum is lighter than steel and conducts heat quickly, which can lead to faster heat transfer to the welder, increasing the risk of burns. Additionally, aluminum welding produces fumes that contain aluminum oxide, which can be harmful if inhaled over time, potentially causing respiratory issues or even neurological damage. Welders must use proper ventilation and respiratory protection to mitigate these risks. Moreover, aluminum's high reflectivity can cause intense light exposure, necessitating the use of appropriate eye protection to prevent eye injuries. Overall, aluminum welding requires specific safety measures to protect welders' health and safety.</p>

- Q: This question asks about the impact of aluminum coils on the quality of welding. It seeks to understand the relationship between the material properties of aluminum coils and the outcomes of the welding process.

- <p>Aluminum coils can significantly affect welding quality due to their unique properties. Aluminum has a high thermal conductivity, which requires more energy to weld, and can lead to rapid heat dissipation, affecting the weld's uniformity. Oxides on the aluminum surface can also interfere with the welding process, causing porosity and poor joint strength if not properly cleaned. Additionally, aluminum's low melting point can lead to distortion and warping if not managed correctly. The use of appropriate filler materials, proper cleaning, and precise control of welding parameters are crucial to achieve high-quality welds with aluminum coils.</p>

- Q: Can aluminum coils be used in the manufacturing of cans?

- Yes, aluminum coils can be used in the manufacturing of cans. Aluminum coils are commonly used in the canning industry as they are lightweight, durable, and provide excellent sealability, ensuring the freshness and preservation of the contents.

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

Send your message to us

Gpc1430h41 Prepainted Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords