Aluminum Foil Facing Good Quality Rubber Plastic for Thermal Insulation

- Loading Port:

- China Main Port

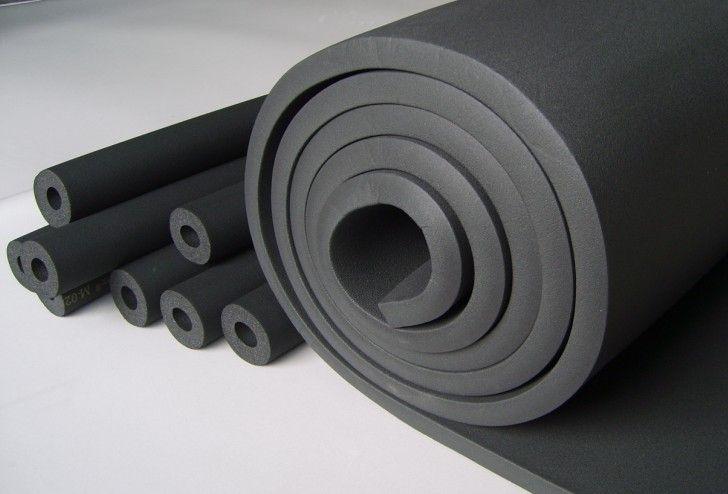

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Description

rubber plastic is a high quality heat-insulating and heat-preservation material which use butyronitrile rubber and polyvinychloride(NBR,PVC) as main raw materials.

The productionprocess includes mixing, tensing and continuous extruding , heating andfoaming, cooling and cutting.

2.Main Features of Rubber Plastic

-Lower heat-conductivity

-Higher fire-blockingperformance

-Damp-proof andWater-proof

-Softness

-Neat and

-Easy to installeasy handing and storage

-Good flexibilityand tenacity

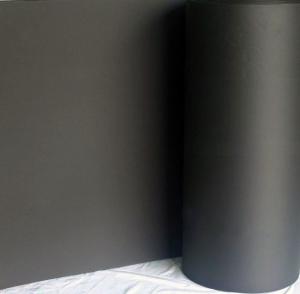

3.Rubber Plastic Images

4.Rubber Plastic Specification

--Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The user is asking if they can reuse their old aluminum foil facing to create new ones once it becomes worn out.

- <p>No, you cannot create new aluminum foil facings from old, worn-out ones. Aluminum foil facings are typically made from a specific type of aluminum that is bonded to a substrate. Once it wears out, the aluminum layer is compromised and cannot be reused to make new facings. Recycling old aluminum foil is the best option to reduce waste and conserve resources. You can recycle aluminum foil, which will then be processed and turned into new aluminum products.</p>

- Q: Is it safe to use aluminum foil as a wrapping material for food to be fried?

- <p>Yes, you can use aluminum foil to wrap food and fry it. Aluminum foil is heat resistant and can withstand high temperatures, making it suitable for frying. However, it's important to ensure that the foil is securely wrapped around the food to prevent any oil from seeping in and to avoid any foil from breaking off into the oil, which could be a fire hazard. Always follow safety guidelines when deep frying with aluminum foil to prevent accidents.</p>

- Q: What is the function or use of aluminum foil facing in construction or insulation?

- <p>Aluminum foil facing is used primarily for thermal insulation in construction and HVAC systems. It reflects radiant heat, reducing heat transfer and improving energy efficiency. It also serves as a vapor barrier, preventing moisture from passing through insulation, which can reduce its effectiveness. Additionally, aluminum foil facing can provide a clean, finished appearance and protect the insulation material from damage and contamination.</p>

- Q: Can the shiny side of aluminum foil be utilized as a reflective surface?

- <p>Yes, aluminum foil facing can be used as a reflector. Aluminum foil has a highly reflective surface, which makes it suitable for reflecting light and heat. The shiny side of the foil is particularly effective due to its smooth and polished finish. It is commonly used in various applications such as cooking, gardening, and DIY projects to reflect heat or light. However, it's not as efficient as specialized reflective materials like mirrors or aluminum-coated fabrics, and it can degrade over time with exposure to elements.</p>

- Q: Is it possible to use aluminum foil with a non-stick coating as a substitute for non-stick baking or grilling pans?

- <p>Yes, aluminum foil facing can be used as a non-stick surface for baking pans or grilling pans. It provides a smooth, non-stick surface that prevents food from sticking and makes cleanup easier. However, it's important to ensure that the foil is heavy-duty and not too thin to avoid tearing during use. Additionally, while it can be a temporary solution, it's not as durable as a true non-stick surface and may require frequent replacement.</p>

- Q: Is it safe to use aluminum foil with a facing layer for storing salad dressings or oils?

- <p>Yes, it is generally safe to use aluminum foil facing for storing salad dressing or oil. Aluminum foil facing is designed to provide a barrier against air and moisture, which helps to keep the contents fresh. However, it's important to ensure that the foil is food-grade and that it does not have any sharp edges that could puncture the container. Additionally, it's best to store these items in a cool, dry place away from direct sunlight to maintain their quality and prevent spoilage.</p>

- Q: This question asks for a method to create a facing made of aluminum foil.

- <p>To make your own aluminum foil facing, you'll need aluminum foil and a suitable adhesive. Start by cutting the aluminum foil to the desired size and shape. Apply a layer of adhesive to the back of the foil, ensuring it's evenly spread. Press the foil onto the surface you want to cover, smoothing out any bubbles or wrinkles. Use a knife or scissors to trim any excess foil. Allow the adhesive to dry completely before handling. This creates a reflective surface that can be used for insulation, decoration, or other purposes.</p>

- Q: Explain the distinctions among various types of aluminum foil facing materials.

- <p>Aluminum foil facing can be categorized into several types based on their composition and application. Type 1 is plain aluminum foil, commonly used for food packaging and general wrapping. Type 2 is aluminum foil laminated with plastic, which offers better barrier properties and is used in flexible packaging. Type 3 is aluminum foil laminated with Kraft paper, providing a sturdier material for packaging and insulation. Type 4 is aluminum foil laminated with polyethylene, which is waterproof and used for construction and insulation. Each type has unique properties, such as barrier resistance, strength, and heat resistance, making them suitable for different applications.</p>

- Q: This question asks about the distinction between aluminum foil made from new raw materials and that made from recycled materials.

- <p>Yes, there is a difference between 'virgin' and 'recycled' aluminum foil. Virgin aluminum foil is produced from newly mined bauxite ore and is considered to be of higher purity. It is often preferred for applications requiring high quality and consistency. Recycled aluminum foil, on the other hand, is made from aluminum waste that has been collected, sorted, and reprocessed. It is more environmentally friendly as it reduces waste and energy consumption. However, recycled aluminum foil may have slight variations in thickness and quality due to the recycling process.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing Good Quality Rubber Plastic for Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords