Good Quality PU Sandwich Panels - Corrugated EPS Sandwich Panel for Prefab Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | corrugated EPS sandwich panel 1. Naked packing in 20' or 40' container 2. Steel pallet with belt in 40' container |

| Delivery Detail: | 15-20 days after receipt of down payment for wall panel |

Specifications

corrugated EPS sandwich panel

1)sound & hot insulation

2)fire&water proof

3)thickness: 25-100mm

4)USD13-28/m2

Packaging & Delivery

| Packaging Detail: | corrugated EPS sandwich panel 1. Naked packing in 20' or 40' container 2. Steel pallet with belt in 40' container |

| Delivery Detail: | 15-20 days after receipt of down payment for wall panel |

Specifications

corrugated EPS sandwich panel

1)sound & hot insulation

2)fire&water proof

3)thickness: 25-100mm

4)USD13-28/m2

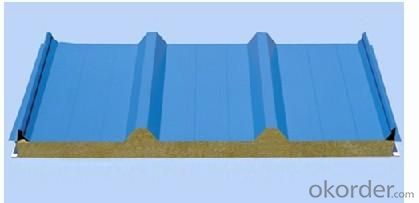

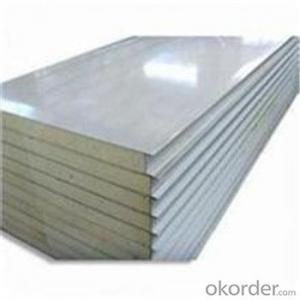

Corrugated EPS sandwich panel for prefab building

Product Description

Corrugated EPS sandwich panel is composed of two layers of pre painted steel sheets with the hard forms of polyurethane as core, which features fireproof materials. It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purification workshops etc, which features temperature-keeping, heat insulation, weight-bearing, weatherproof with the rich color and good appearance.

Specification: | |

Surface Texture and Appearance | Small wave, Flat, Big rib |

Thickness of steel plate | 0.35-0.6mm |

Heat Insulating Material | EPS(polystyrene) |

Thermal conductivity | 0.044w/m.k |

Unit Weight of Core Material | 7-20KG/m3 |

Thickness of Core Material | 40mm, 50mm, 75mm, 100mm,(min thickness for roof: 30mm) |

Effect Width | 950mm, 1150mm |

Color | White grey, Sliver, Sea Blue, Red, etc |

Recommended Coating | PE, PVDF, HDP |

Recommended Plating | Hot-dip galvanized, Al-Zn coated |

Features | 1.Fire resistant; 2.Heat Insulating; 3.Light Weight |

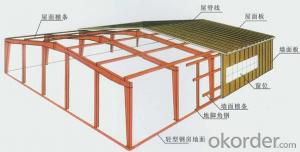

Corrugated EPS sandwich panel application

* Steel structure warehouse

* Temporary office & accommodation

* Commercial prefab building for poultry

Packaging & Shipping

In order to save the space & load the max quantity, it is normally without packing. But steel plate pallet packing for corrugated EPS sandwich panel is also workable.

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- (Including: Fluorocarbon metal paint, fluorocarbon solid paint, real stone paint, imitation stone paint, granite, relief supporting, imitation brick texture, texture matching, etc) and insulation materials series (including: XPS , EPS, PUR, phenolic board, rock wool board, ultra-thin insulation board), for the old and new concrete, steel structure, real brick wall, hollow brick wall, brick wall wall, combined with the company to install patent, Construction of the wall installation TDD insulation decorative board is not only suitable for the new building exterior insulation and decoration, but also for the old building of low-carbon energy-saving decorative transformation, and not affected by regional differences

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. These panels provide excellent insulation, durability, and aesthetic appeal, making them a practical choice for creating a modern and visually appealing showroom. Additionally, sandwich panels can be customized to meet specific design requirements and offer ease of installation, making them a suitable option for automotive showrooms.

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q: Color steel sandwich panels and color steel plate What is the difference

- Excuse me, where are you in? Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The There is that you can use .7 inside the expansion screw, to the hardware store to find can match. You can also use welding, then a long screw, is also very simple.

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are typically made of two outer layers of rigid materials, such as metal or wood, with a layer of insulating material in between. This insulating layer helps to absorb and dampen sound waves, making sandwich panels an effective choice for noise barriers. The insulating material in sandwich panels can be made of various materials, such as mineral wool or polyurethane foam, which have excellent sound absorption properties. These materials are designed to trap and dissipate sound energy, preventing it from passing through the barrier and reducing the noise levels on the other side. Sandwich panels for noise barriers can be customized to meet specific noise reduction requirements. Different thicknesses and densities of the insulating layer can be used to achieve the desired level of sound insulation. Additionally, the outer layers can be designed to be reflective or absorptive, depending on the desired acoustic performance and aesthetic preferences. Sandwich panels offer several advantages for noise barrier applications. They are lightweight, making them easy to install and transport. They also have a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Furthermore, sandwich panels can be designed to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. In conclusion, sandwich panels are a suitable choice for noise barriers due to their sound absorption properties, customization options, and durability. They can effectively reduce noise levels and provide a quieter environment for various applications, such as highways, factories, residential areas, and commercial buildings.

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

- Q: The stove is dedicated to the plastic used for plastic paper

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, maintenance-free features, has been widely used Caigang sandwich panels Is the current building materials in a common product, not only can be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor. The tile is used for the panel for the wall

Send your message to us

Good Quality PU Sandwich Panels - Corrugated EPS Sandwich Panel for Prefab Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords