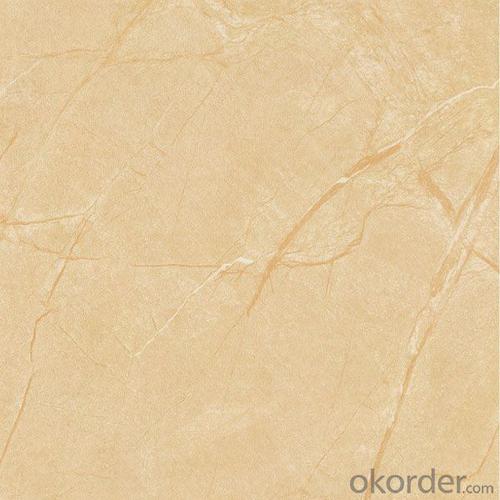

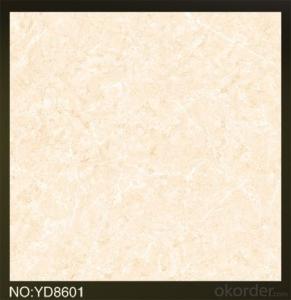

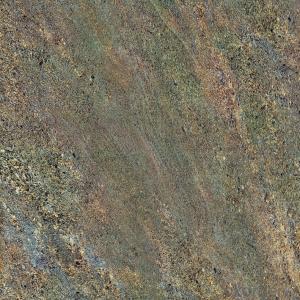

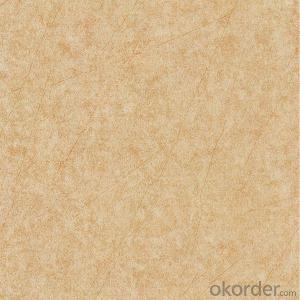

Glazed Porcelain Floor Tile 600x600mm CMAX-V6062

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information:

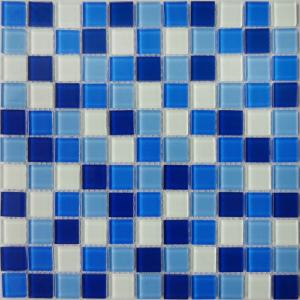

Tile Type | Glazed Porcelain Tile, floor tiles |

Certificate | ISO13006, ISO9001 |

Finish | Matte Finish, Lapato Finish, Rough Finish |

Size | 60x60 mm |

Selection Range | Several Colors available |

Features:

1) Unique natural sandstone image designs and exclusive quality;

2) Used for indoor & outdoor wall and floor decorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof, alkali-proof, durable

4) Material: porcelain

5) Basic size: 600x600x9.8mm, 100x600mm, 150x600mm, 300x300mm, 300x600mm available based on clients’ requirements;

6) Available dimensions

Material | Porcelain |

Dimension | 600x600x9.8 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The glazed porcelain tile is widely used for interior house flooring, hotel lobby flooring, exclusive brand showroom, clubs villas as well as other public sites.

We could go with OEM model, making 2nd production based on client’s requirement;

We could offer flexible service on shipment and better support on payment term;

Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as 2nd production and final package.

Specification and technical parameter:

· Matte Finish, Lapato Finish, Rough Finish

· Water absorption:<0.1%< span="">

· Anti-Resistance: R10

· Delivery Time: within 15~20 days after order confirmation.

· Package standard: 4pcs/carton, 40 Cartons/pallet, 32 Kgs/Carton.

- Q: I have a bathtub that the bottom row of tiles are getting loose on the top portion. A few have come out.The row above seems ok.Can the bottom row be resealed or replaced without interfering with the upper tiles?If so how?

- Yes you can just be patient and remove the loose tiles which should not be hard to do. The reason that they have turned loose is because of moisture behind the tiles. Be sure you have a good stable surface for the tiles that you put back to adhere to. You may have to lay a film of masonry of something to give you a solid surface to hold the replaced tiles. As for as glue, I would use a adhesive that is called F26 and it is multipurpose to reattach the tile. I will guarantee that those tile will never come off again.

- Q: What is the double tiles of tiles? How to distinguish polished tiles from the surface and throw glazed tiles. What is the thickness of each? What kind of microcrystalline stone?

- Now the tiles, the general sub-base material and fabric. The base material and the fabric are generally not the same. At the end of the material commonly known as the blank, the general use of materials, such as kaolin, river sand, according to a certain proportion of compatibility. Fabric in order to pursue different artistic effects, often in the general use of materials into the whole particles, semi-particles and other translucent materials and color materials. Although seemingly two layers, but the two materials are mixed before firing, after firing does not affect the overall quality. "Double effect" one can guarantee the surface of the different artistic effects, two can save production costs. Because the fabric which joined the translucent materials and colorants, the cost is high.

- Q: Is it good to use a white cement?

- Paste the tiles with cement paste, back seam with a good sealant, because the hook is not easy to change color, will not seepage, we do when the external walls are used

- Q: I want to know if it‘s necessary to use any special underlayment, or any additional steps required to successfully lay ceramic tile over a wood plank floor. Thanks!

- The right way to do it would be to remove the flooring and lay down some hardi backer or some cement board. However - if your wood floor is very very flat, and you consider the areas where that wood floor + the thickness of your tile meets up with other floor surfaces (e.g. carpeting or door door thresholds), it might be the easiest thing to do. Tile is a lot of fun. Don't skimp on making the right cuts and be sure to use spacers. Depending on what kind of tile you use - go with a smaller (1/4 or less) spacer so you have less cleanup with your grout. [Edit - I definitely agree with Crazy Man below. The waterproofing layer is a definite! Make sure you give it adequate time to dry, and then make sure you let the mud (adhesive) dry completely before grouting.] You might also consider something other than ceramic tiles, although there are some newer styles that are quite nice. A sealed porcelain tile or slate looks so nice.

- Q: I have extra floor tiles that i had my kids paint and i want to put them together for my husband for fathers day. any ideas on how to do that?

- If the tiles are 12x12 it depends on the number of tiles you had them paint. You could put them in album frames and hang like pictures; you would get a piece of 1/4 plywood cut to size at Home Depot, paint the wood, glue them down and put hangers on the back; You could get cut plastic sheets or acrylic and arrange the tiles on the sheets, let's say if you had four, you could put four square in the center with 1 1/2 inch between them and two inches around the outside (30x30) You could then get the kids to decorate the border on the plastic with paint, beads, mosaic.

- Q: i mean i know they make tiles obviously, but how do they go about doing that exactly?

- Hello Most of the tile makers now use dust clay(fine powder) .they have a standard 6x6 two part mould that they fill with a set amount of the powdered clay insert the filled mould in to a fly press of similar type of press remove from the mold decorate glaze and fire in the kiln. this is just to give you some idea. The traditional way is to use plastic clay that's wet clay that you can press into a tile mould by hand or a small press remove leave to dry and then fire when fully dry.You can fine a few help full books on the internet or the Library. Cheers Bob a Job

- Q: I‘m remodeling my kitchen and there is ugly floor to ceiling wall tile. My contractor says can‘t put up drywall without reframing (which would be expensive). So does anyone have suggestion on what to do with this wall?

- If the tiles are on a villa board just rip it off the studs and take out any nails or screws so the drywall can just be fixed straight onto the studs. First you have to knock one of the tiles off, since that walls is being redone this won't upset the apple cart. Just be care when taking off the tile, because I was doing the same things years ago and I hit a tile with a hammer and it shattered sending bits of razor sharp tile fly one cutting my arm, wear eye protection and put something like a towel over the tile so it won't fly everywhere. Once you've knock off a tile if there's board behind it you're in luck, just continue doing as you got the first tile off and clear the studs of anything that will get in the way of the sheetrock. If not you'll need to batten the wall out to take the sheetrock as your contractor said Well depending on what you intend to do with the wall, will you re-tile? If you intend to re-tile just use a chisel and carefully knock them off the wall taking as much of the tile mortar off as you can, it doesn't matter if there's a little unevenness, but you can't have high spots all over the wall, because if you re-tile the high spot will cause the tile to ride on ithe high spots making it hard to tile, if it's just a little the tile compound/mortar will even out around it during tiling. I'd take anything higher than 1/8 off using a Scutch Hammer. ...

- Q: i need help putting up counter tops and backsplashes.(tile)

- Yes you do get tile cement that will stick to smooth surfaces. You can all so rough the surface up with a coarse sandpaper. You do get a bonding liquid that you apply before you put the tile cement it helps with the bonding. Just make sure the counter top isn't flexible because that can cause problems All so make sure when you fill the tile joins with grout that it fills it good and make sure your grout is water resistant

- Q: I found answers about laying tile and a backer board over linoleum I didn‘t know if they would be the same. What would cause tile to crack if it‘s places directly on concrete?

- do not lay ceramic tile over vinyl, vinyl moves. Ceramic does not and will crack

- Q: Specifically, what type of drill bit is required that won‘t chip the tile.

- Tile of this type is baked, and is therefore very hard and the glaze is a very slick surface that the drill bit has trouble getting a bite on. You could try using a center punch to mark the hole location, being careful NOT to break the tile; or use a bit made for glass (uses diamond dust and actually grinds the hole rather than drilling it.)

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-V6062

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches