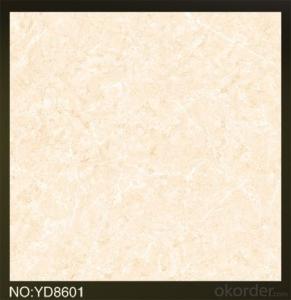

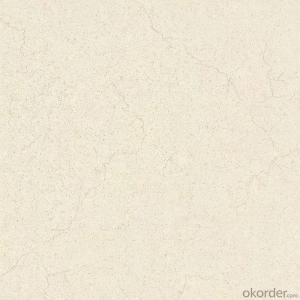

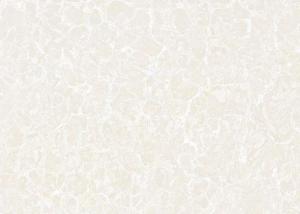

Glazed Porcelain Floor Tile 600x600mm CMAX-H6028

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

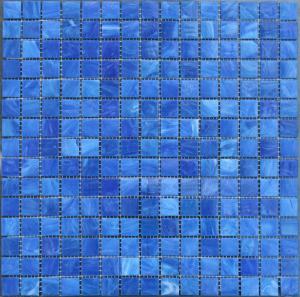

You Might Also Like

Specification

Product Brief Introduction

The glazed porcelain floor tile is wildly popular in Europe, North America and Middle East. The modle NO. CMAX-H6028 is one of the popular designs in the present market. Just like other glazed porcelain floor tile, it could be used for interior floor and wall for apartment, villa, as well as other public areas, due to its unique antique feel image and texture. Besides, it is also proper for retails and distribution marketing channels.

Product Features

Excelent glaze surface and porcelain tile body

Grade AAA quality standard only

The basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm based on the actual project needs.

Strict quality control system on water absorption rate, color shade, deformation, anti-pollution, slip-resistance, abrasion resistance .

Compititive prices

Standard export packing: Pater Carton+ Solid Wooden Pallet

Fast production arrangement

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006,EN14411.

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1300 N

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.5%

Wearing Strength: 《1600 mm3

Slip Resistance: 》 0.5

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

For 300x600mm, 8pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6 m2/20’Fcl

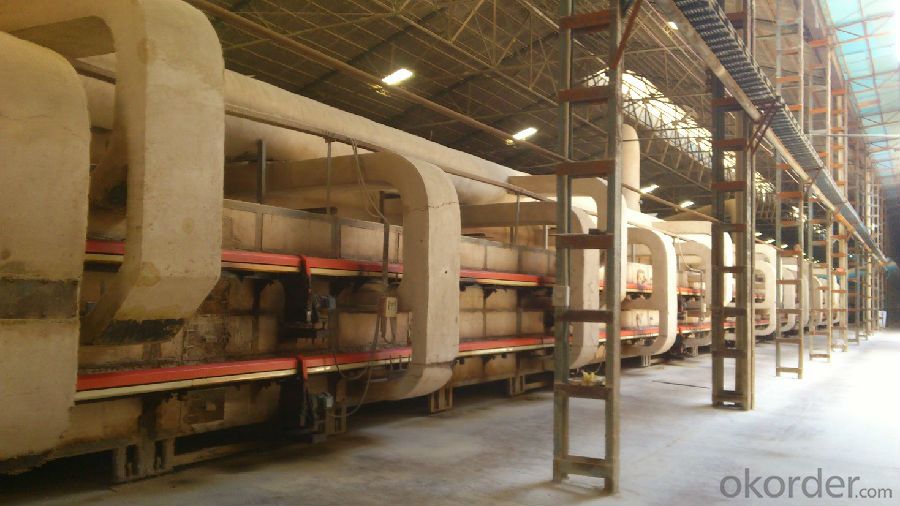

Production Line & Package

FAQ

1. What is the delivery time after we paid the deposit?

—— Normally, we shall get all items ready for loading within 3 weeks after we get the deposit or the formal Letter of Credit. For orders which demand cutting job, it will take a longer time.

2. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

3. Could we be your exclusive agent in our country?

—— Possibly. For some countries we are hoping to find a proper partner in working market together. For sure we need to have a good talking for the details.

4. Could we arrange the our own QC to check the items before container loading?

—— Yes, of course. Your quality checking will be welcome all the times.

5. What is the MOQ for this tile?

—— Normally the MOQ is one 20’ container. For those models whose production could be arranged frequently, we could mix 2 or 3 models in one container.

- Q: I was told by one guy at Menards to use a 1/4 teeth trowel for 6-1/2‘‘ x 1/4‘‘ floor tiles. I am worried this will be too much glue and will ooze out the 3/16‘‘ gaps between tiles. then it will be a nightmare mess, and can‘t grout.Also do you just lay the tiles on the glue? or press down ?how much?Thank you very much

- Trowels come in several shapes and sizes generally from 3/16 v-notch to half-inch square notch. The proper trowel size is basically matched to the tile size; the smaller the tile – the smaller the trowel; the larger the tile – the larger the trowel. I'd use 1/2 x 1/2 square notch for floor tiles that large.

- Q: How to completely remove the double-sided adhesive on the tile?

- In addition, you can also use the heating method to double-sided adhesive glue softening: blowing with a hair dryer to soften the glue, when the double-sided adhesive adhesion becomes weak, you can easily remove. If there is a little traces, with the removal of nail polish to light water to wipe. Finally, in the clear time, whether it is to use to light water or vinegar, be sure to make these supplies completely wet double-sided adhesive marks, can be easily and effectively removed Oh! If the conditional alcohol + eraser effect is very good

- Q: How is the acceptance of tiles after construction?

- Acceptance of several main parts: first within two meters of the error shall not be greater than 2mm, the joints should be neat, uniform size, no hollowing, not loose, with two meters long ruler or by the foot of acceptance. Second, you can use a small hammer in the ground or the walls of all the light tapping, no empty drums. Finally, pay attention to the drainage requirements of the floor tile slope should meet the drainage requirements, and ground leakage should be tightly integrated.

- Q: I wish to change the bathroom colour,re-tileing is too expensive so maybe painting the tiles is a option howbest do i prepare for this

- depends on the type of paint used and you may need to rough them up, but b 4 u do that go and ask at a specialist paint shop as there are products / paints out there that you can use.

- Q: I want to know if it‘s necessary to use any special underlayment, or any additional steps required to successfully lay ceramic tile over a wood plank floor. Thanks!

- yes, you'll need a good underlayment. The reason is that the independent movement of the planks as weight loads the floor will cause torque between two planks, cracking the mortar and the grout and perhaps the tiles themselves. Its enough work to lay the tile that you definately don't want to do this without the underlayment. And I'm a guy that will lay tile over a well secured vinyl floor, so I'm not one of those there's only one right way to do it people. But in this case, you'll be unhappy with the results without a sanded plywood or cement board underlayment.

- Q: Hello. To clean a fridge water was poured on the lower section . The water spilled out onto the floor where white tiles are. I left for a minute and came back and saw that the white tiles had grey blotches or spots. What happened, and how can I cure this?

- Tile won t stain under normal circumstances so I suspect the glaze is a bit worn off rt in front of the fridge.. That can be a wet spot that will dry eventually or stain the tile body in which you have no choice but to r and r the tile(s).. GL

- Q: Sanding parquet floor tiles, advice please.My hall floor is covered in parquet tiles.The tiles themselves are made up on 1 inch by 5 inch sections, 5 to a tile.The tiles are laid so that the grain on the tiles is alternate and opposite its neighbour. So the grain on some go North-South, the next in line goes East-WestMy sander has a face larger than any one tile.Do I have to sand along the grain, in which case I‘d have to buy a tiny grinder, or can I just sand all over the tiles and not bother about sanding along the grain? Assuming I have sanded, how do I seal the completed job? Varnish?

- First okorder / wood finish. It ain't cheap but you will be able to add new coats of finish later on without having to completely refinish the whole floor. You can rent a 'square sander' from Home Depot for abut $40 a day. It uses 4 six inch disk type sand paper. It doesn't dig in when started which allows a first time DIY person to do a good job. You move it around by putting pressure on the handle, real easy to use. Takes longer than a belt sander but you won't make mistakes. Make sure when you rent it that you get different size paper AND that they will stick (like velcro) to the sander unit face. You don't want to get home, start to use it and the sand paper disks fall off!! Had that happen with one. If you have a large floor to do rent the sander around 3 pm. You get 24 hours so you can sand from 3-11pm, go to bed, then start over in the morning. Otherwise you have to work from morning to evening. Makes for a long day.

- Q: How to introduce tiles

- According to varieties: glazed tiles, quintana brick (homogeneous brick), polished tiles, tiles, porcelain glazed tiles (antique brick) Tile Features: Size: Size of the product size, can save construction time, and neat and beautiful. Water absorption: the lower the water absorption, the better the degree of vitrification, the better physical and chemical properties of products, the more difficult due to climate change thermal expansion and contraction caused by cracking or peeling. Flatness: good tiles of flatness, the surface is not bent, not Qiaojiao, easy construction, construction after the ground flat. Tile strength: high flexural strength, good wear resistance and resistance to stress, easy to wear, timeless, suitable for public places. Color: the tile on the floor, fight in a square meter, from the three meters to see whether there are different colors or can not be connected, resulting in beautiful obstacles. --- These points are the key to identifying the quality of the tile

- Q: I need to know if flexbond is the best stuff to use for this type of job for a do it yourselfer. I have never worked with this stuff. I have only used regular thin set mortar in the past. Is it hard to work with?? And to lay the tiles this large do I have to butter the mortar on or can I just trowel it onto the plywood floor?Thanks, Fran

- Is the floor really straight, clean, and rigid? If so, thin set is better. How about a water or vapor barrier? Watch some of the Holmes on Homes shows from Canadian TV. He works in the Toronto area and is the best. Everyone kids him because his motto is :Make it right!. Shows #54, 72 and 67 might help.

- Q: some brands of vitrified tiles in india?

- 9.88 mm Kajaria Tiles Regent Granito Marbito

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-H6028

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches