Glass Wool Insulation Fiber Glass Wool Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Glass Wool For Insulation Glass Wool Board

1.Structure of Fiber Glass Wool For Insulation Glass Wool Board:

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

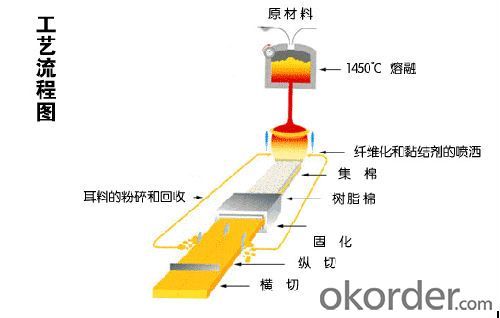

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Fiber Glass Wool For Insulation Glass Wool Board:

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

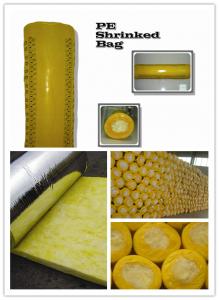

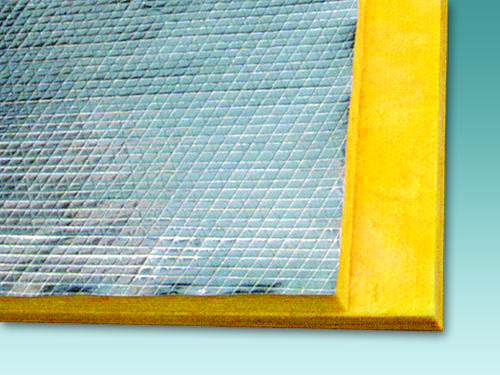

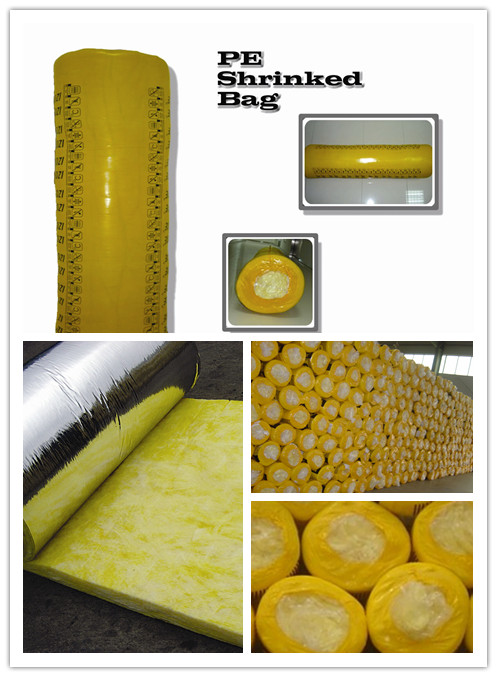

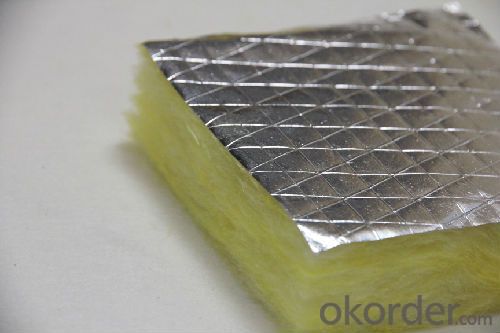

3. Fiber Glass Wool For Insulation Glass Wool Board Images

4. Fiber Glass Wool For Insulation Glass Wool Board Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

- Q: What is semi-rigid glass wool board

- Commonly used in roofing, the density of about 120-150kg / m?.

- Q: How much is the unit weight of thermal insulation glass?wool?boards at least? How much is the unit weight of sound absorption glass panels?

- They are from twenty to less than eighty.

- Q: Which one among polystyrene?boards, rock wool boards and glass?wool?boards is the best materials for external wall thermal insulation?

- Polystyrene?boards are better in terms of external wall thermal insulation materials but now polystyrene?boards are not allowed to use. Rock wool and glass wool can be used, but they need good waterproofing treatments.

- Q: Centrifugal glass wool board and polyurethane foam, which has better thermal insulation performance?

- It depends on where you use, if there is restrictions on the space, you'd better use centrifugal glass wool, and if the place is narrow, you can use foam materials, their performances are almost the same.

- Q: How to increase soundproof performance of houses(with glass wool)?

- If you want to be simple, use sound barrier mats. If you want to be a completely soundproof environment, use sound absorption materials. If you use glass wool, you have to be aware of skin and respiratory tract infection.

- Q: Whether the rigid section of aluminium foil glass wool can be twined with glass fiber cloth

- Yes, you can add glass silk cloth when construction and production

- Q: Does the glass wool can be the grapes thermal insulation in winter?

- this can be the experience talk after using it. 3, or capable of burning: the glass wool you chose is A-grade material, or the A grade insulation material have this kind of glass wool as you said. 2, seedling growth conditions, thermal insulation is whether hot or cold insulation. this non-combustible material has national standard, if you want to use for external walls, you also observed carefully, but the performance of rock wool thermal insulation is poor, and there is a kind of basalt rock wool, it also have the fire side, that is non-flammable, of course, it at least 5 cm or more. Of course, you have to roast on the fire, this is pretty troubling: I suggest that if there winter is quite cold, the designing institute will issue relevant documents to work out the number of glass wool from the market point of view: As the thickness, you have to consider in all round, so your choice is the right one.

- Q: What is the price of glass wool felt ?

- Now, factory price of glass wool is about 2500 per ton.

- Q: Are thermal insulation glass?wool?boards hydrophobic?

- It has poor performance in fireproofing and thermal insulation, and has a high heat conductivity coefficient. At present, it meet requirements of thermal insulation and energy saving policy for external walls. Glass wool is heavy itself, easy to slag. It can lead to serious pollution during construction and produce cancerogenic?substance. It is highly absorbent, and easy to peel off. The operation life of which is short.

- Q: what is the specifications of glass wool and rock wool shell and tube?

- diameter. The first is the unit weight. ,thickness

Send your message to us

Glass Wool Insulation Fiber Glass Wool Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords