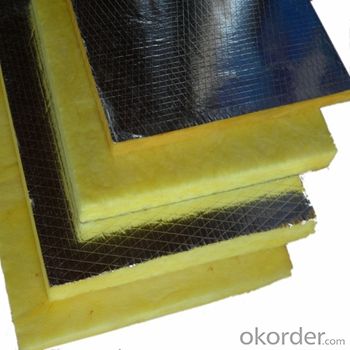

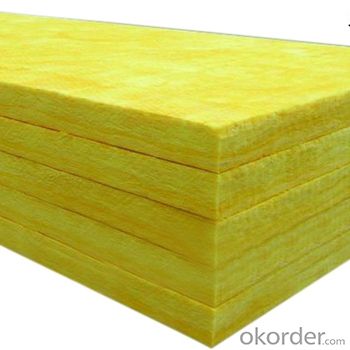

Aluminum Foil Faced Glass Wool Board 10kg/m3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Glasswool Description

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Glasswool Specification

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

Item | Unit | Index | Measured value | Remarks |

Bulk density | kg/m3 | 10-96 | 10-96 | GB/T 13350-2000 |

Average diameter of fibers | m | < 8.0 | 4.0-6.0 | GB/T 13350-2000 |

Moisture resistivity | % | > 98 | > 98.5 | JISA9512-2000 |

Thermal conductivity | W/m.k | 0.049-0.042 | 0.045-0.032 | GB/T 13350-2000 |

Incombustibility | Incombustible | Up to standard (Grade A) | GB/T 13350-2000 | |

Sound absorption coefficient | 1.03product reverberation positioning 24kg/m3 2000HZ | GB/J47-83 | ||

Max. working temperature | 400 | 410 | GB/T 13350-2000 |

3. Main Features

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

4. Glasswool Images

5. Scope of application

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc

6. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: what is the quota of glass wool rigid section of thermal insulation.

- Now, I also encountered the same problem, lz, can you tell me what quota should be used?

- Q: What are the uses of glass wool thermal insulation materials?

- Thermal insulation for external walls, and air conditioning ducts. They also play a role in fireproofness.

- Q: How to conduct thermal insulation construction of external wall glass wool?

- Firstly paste the insulation board, and then paint coat on it.

- Q: What harm dose glass fiber cotton do to human body?

- We are glad to answer your questions.1 Glass wool damages human health 1 Lots of glass fibers float out during the construction or after the aluminium foil is damaged.The glass fibers may cause serious damage to air quality and human health. According to the lung biopsy for workers who contact glass fiber, there are dust-cell focus, mild hyperplasia of collagen, lung cancer and lung abscess in the lung tissue.People who contact glass fibers may suffer from conjunctivitis and keratitis which will develope into corneal opacity and local abscess when the situation worsens.When the fiber diameter and the length is similiar, the glass fiber can also produce similar toxicity and carcinogenicity with asbestos.2 it is not environmentally friendly and is forbidden to be used in the Olympic venues.In view of the environmental factors, Ministry of Construction and the Beijing Municipal Health Bureau released the relevant documents to regulate the use of glass wool.In line with environmental protection, International Olympic Committee prohibit the use of glass wool in Sydney Olympics and Beijing 2008 Olympic Games.3 it dose not save energy.The aluminum foil covering the glass wool breaks easily. Besides, glass wool has an open cell structure. once it is damaged, water vapor will enter and the wet resistance factor is 0, which means that the insulation effect is reduced, energy is wasted and operating costs increases.

- Q: What are the differences between the glass fiber and glass wool? ?

- Winder is corrosion resistant, but with a weakness of brittle property and the advantages including good insulation, small volume density, good corrosion resistance, good shape, equivalent to a human hair1& # 47, stable chemical property, circuit boards and other fields in national economy, wire drawing, each beam of fiber precursor is composed of hundreds of even thousands of monofilaments; 20-1 & # 47, whose chemical composition belongs to glass, forming a kind of cotton-like material. It is made by melting in high temperature with glass balls or glass wastes as the raw material: Glass fiber or fiberglass) is a kind of high performance inorganic nonmetallic material and a kind of manmade inorganic fibre; 5. Glass wool is made by fibering the melten glass. Glass wool belongs to one of the glass fiber categories with good sound absorption performance. Glass fiber is commonly used as reinforcing material in composite material, low thermal conductivity, made by weaving and other crafts great varieties, heat insulation, high mechanical strength, high heat resistance. Glass fiber (formerly known in English as, is a kind of inorganic fiber, whose monofilament diameter is from several microns to more than twenty microns, electrical insulating material and heat insulation material, poor wear resistance

- Q: What is the density of high-temperature glass wool ?

- Centrifugal glass wool felt, steel glass wool felt, roof dedicated centrifugal glass wool felt,aluminum foil glass wool blankets centrifugal glass wool felt. glass wool is added with binding agent and cured under high temperature into panniform. Its bulk density is lighter than panel,good elasticity, cheap and easy construction. Centrifugal glass wool felt major technical indicators: Centrifugal glass wool felt Bulk density: (Kg / m3) 14,16,20,24,32,48 centrifugal glass wool felt Thermal conductivity coefficiency. 0.038w / m.h. ℃ centrifugal glass wool felt Size: Width 1200mm, length 11mm 22mm (negotiable) centrifugal glass wool felt thickness: 25-150mm (negotiable) centrifugal glass wool felt Uses: fireproofing, thermal insulation, sound absorption for high-rise buildings and refrigeration. Thermal and cold insualtion of air-conditioned rooms, vehicles, ships.

- Q: Centrifugal glass wool board is used to do what

- Mainly used for high-rise buildings within the wall compartment, ceiling, metal duct or bellows insulation, studio, room and other noise absorption within the noise.

- Q: What is the density of glass wool?

- Usually, wool thickness is15MM 25MM 30MM 40MM or 50MM .. Unit weight is 12K 16K 24K 32 or 48K. Glass wool with high unit weight should be reserved. And the price depends on the purposes.

- Q: What's the difference between glass?wool?board and rock wool board ?

- In fact, it is very simple. Glass wool is processed from glass (silicon?dioxide) , while rock wool is made from basalt or diabase through high temperature refining equipment, which are two completely different products. Hope it is helpful.

- Q: What industry does the glass wool belong?

- Glass wool belongs to building materials,is mainly used in steel structure and color steel movable house.

Send your message to us

Aluminum Foil Faced Glass Wool Board 10kg/m3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords