Glass Fiber Textiles - Fiberglass Fabric, Cloth, Rope & Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

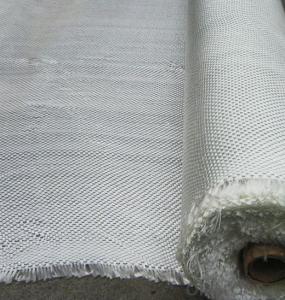

Fiberglass Fabric / Fiberglass Cloth / Fiberglass Rope / Fiberglass Tape

- Textured fiberglass textiles are composed of cloth, tape, twisted or braided rope etc.

- Having a maximum continuous operating temperature of 550℃.

Advantage of Textured Fiberglass Textiles

- Low thermal conductivity

- Electricity insulation

- Corrosive resistance

Application of Textured Fiberglass Textiles

Textured fiberglass textiles can be performed in process industries as fire curtains, gaskets or sealing in kiln, furnace and heaters etc. Application has been extended to the building industry as reinforcement material.

Size of Textured Fiberglass Cloth

Thickness:0.8mm-4mm (0.032"-0.157")

Width:800mm-1830mm (31.5"-72.05")

Size of Textured Fiberglass Tape

Thickness:0.8mm-6mm (0.032"-0.236)

Width:13mm-750mm(0.512"29.53")

Size of Textured Fiberglass Twisted Rope

Diameter.3mm-50mm(1/8"-2)

Size of Textured Fiberglass Round Rope

Diameter:4mm-50mm(4/25"-2")

Size of Textured Fiberglass Square Rope

Diameter:4mm-50mm(4/25"-2)

Photo of Fiberglass Texitle

- Q: Can glass fiber textiles be used in curtains and drapes?

- Yes, glass fiber textiles can be used in curtains and drapes. Glass fiber textiles, also known as fiberglass fabrics, are lightweight, durable, and have excellent thermal and acoustic insulation properties. These qualities make them suitable for use in curtains and drapes, as they can help to regulate the temperature in a room and provide soundproofing. Additionally, glass fiber textiles are often fire-resistant, which can be a valuable safety feature in curtains and drapes. Overall, glass fiber textiles offer a practical and functional solution for incorporating insulation and safety into curtains and drapes.

- Q: Can glass fiber textile be used in prosthetics?

- Yes, glass fiber textile can be used in prosthetics. It is commonly used in the construction of prosthetic limbs due to its lightweight, strong, and durable properties. Glass fiber textile materials provide structural support, allowing prosthetics to be more comfortable and functional for individuals in need of artificial limbs.

- Q: Are glass fiber textiles prone to shrinking?

- No, glass fiber textiles are not prone to shrinking. Glass fibers are known for their high dimensional stability and resistance to shrinkage, making them a reliable choice for textile applications.

- Q: What are the properties of glass fiber textiles?

- Glass fiber textiles, composed of fine glass fibers woven together, are a type of textile material. This fabric possesses several distinctive characteristics. Primarily, glass fiber textiles exhibit a remarkable strength-to-weight ratio. Despite their lightweight nature, they possess exceptional strength and can withstand significant tension and pressure. This quality renders them suitable for numerous applications that require strength, such as reinforcement in the construction industry. Furthermore, glass fiber textiles display excellent resistance to heat. They possess a high melting point and can endure elevated temperatures without compromising their structural integrity. Consequently, they prove ideal for applications involving exposure to heat or fire, such as insulation materials and protective clothing for firefighters. Moreover, glass fiber textiles possess outstanding resistance to chemical corrosion. They remain unaffected by acids, alkalis, and other corrosive substances, making them suitable for environments with potential chemical exposure. This characteristic also renders them favorable for manufacturing specific types of filters and chemical-resistant clothing. In addition to their strength, heat resistance, and chemical resistance, glass fiber textiles are renowned for their exceptional electrical insulation properties. Due to their low electrical conductivity, they do not easily conduct electricity. Consequently, they find utility in applications requiring electrical insulation, such as the production of electrical wires and cables. Lastly, glass fiber textiles are non-combustible. They do not readily ignite and do not contribute to the spread of fire. This attribute makes them highly desirable for use in fire-resistant materials like curtains, upholstery, and protective clothing. In summary, glass fiber textiles possess a unique combination of properties, including high strength, heat resistance, chemical resistance, electrical insulation, and non-combustibility. Consequently, they prove versatile and suitable for various industries and applications, ranging from construction and insulation to electrical and protective clothing.

- Q: Can glass fiber textiles be used in reinforcement of metals?

- Yes, glass fiber textiles can be used in the reinforcement of metals. Glass fiber textiles are commonly used as a reinforcement material in composites due to their high strength and flexibility. When combined with metals, they can enhance the mechanical properties of the metal, such as increasing its tensile strength and stiffness. The glass fibers act as a reinforcement, providing additional support and improving the overall performance of the metal.

- Q: Can glass fiber textiles be used for insulation?

- Yes, glass fiber textiles can be used for insulation. They are commonly used in various applications such as buildings, pipes, and electrical equipment to provide thermal insulation due to their low thermal conductivity and high resistance to heat transfer.

- Q: What are the different bonding methods for glass fiber textile?

- Glass fiber textile can be bonded using various methods, each offering unique benefits and applications. 1. Adhesive bonding: In this approach, a specific adhesive is applied to the fabric and then cured to create a robust bond. Adhesive bonding is commonly employed in industries requiring flexibility and strength, such as sports equipment or automotive part manufacturing. 2. Heat bonding: Also known as thermal bonding, this method involves melting the fibers together using heat, resulting in a solid bond. Heat bonding is often used to join multiple layers of glass fiber fabric, creating a thicker and stronger material. It finds extensive use in the production of laminated glass fiber composites. 3. Stitch bonding: This technique employs stitching or sewing to bond the glass fibers. A needle and thread are used to sew the fibers together, creating a durable and sturdy bond. Stitch bonding is frequently utilized in applications where flexibility and breathability are essential, like clothing or upholstery manufacturing. 4. Weaving: This method interlaces the glass fibers, forming a fabric. The fibers are woven using a loom, crossing over and under each other to create a stable structure. Weaving is commonly employed in producing glass fiber textiles like fiberglass cloth or fiberglass tape. 5. Knitting: This technique involves interlocking loops of glass fibers to create a fabric. Knitting machines or hand knitting needles are used to form the loops, which are then secured together to produce a cohesive material. Knitting is often preferred for glass fiber garments or accessories due to its stretchiness and comfort. In summary, the bonding method chosen for glass fiber textiles depends on the specific requirements of the application, such as strength, flexibility, or breathability. Each method has its own advantages and limitations, and manufacturers select the most suitable approach based on the desired properties of the final product.

- Q: Can glass fiber textiles be used in electronic components?

- Yes, glass fiber textiles can be used in electronic components. They are commonly used as insulation materials for wiring and circuit boards due to their high electrical resistance and heat resistance properties. Glass fiber textiles provide mechanical strength and stability to electronic components, making them suitable for various applications in the electronics industry.

- Q: Is glass fiber textile hypoallergenic?

- Glass fiber textiles are generally considered hypoallergenic. Unlike natural fibers such as wool or cotton, glass fibers do not contain any organic matter that can trigger allergic reactions. They are also resistant to mold, mildew, and other allergens, making them a suitable choice for individuals with allergies or sensitivities. Additionally, glass fiber textiles are typically non-toxic and do not release any harmful particles or chemicals into the air, further reducing the risk of allergic reactions. However, it is important to note that individual sensitivities can vary, and some people may still experience mild irritation or discomfort when in contact with glass fiber textiles.

- Q: Are glass fiber textiles fire-resistant?

- Yes, glass fiber textiles are fire-resistant.

Send your message to us

Glass Fiber Textiles - Fiberglass Fabric, Cloth, Rope & Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords