Glass Fiber Textile Reinforced Microporous Insulation Board for Ladle Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | M5100 | service temperature, max.: | 1150 C | Thermal conductivity, @800 C: | 0.035 W/m.K |

| typical density: | 280 kgs/m3 |

Packaging & Delivery

| Packaging Details: | wooden cases |

| Delivery Detail: | 10 days |

Product Description

M5100 Panel is rigid finishing from microporous technology , with opcified blend of filament reinforced fumed silica, which provides a superb thermal performance.

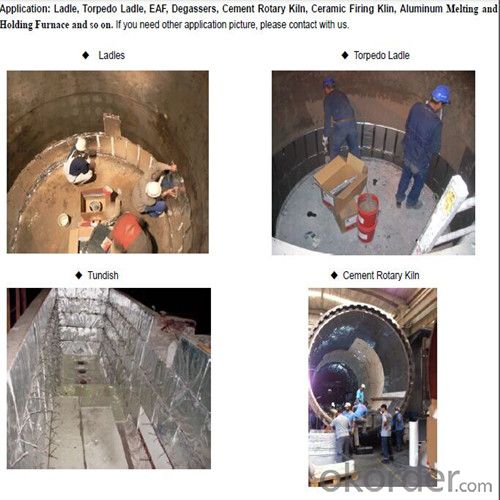

It is an ideal back-up insulation for various industry where the high temperature is needed, with a long time exposure of 1150 °C at highest.

M5100 Panel ---Various coverings : Naked Panels, Aluminium Foil covering, E-class Fibre Cloth Covering, Fibre Paper covering.

M5100 Panel—Four Grades available : 850 , 1000, 1100, 1200

Properties & Advantages

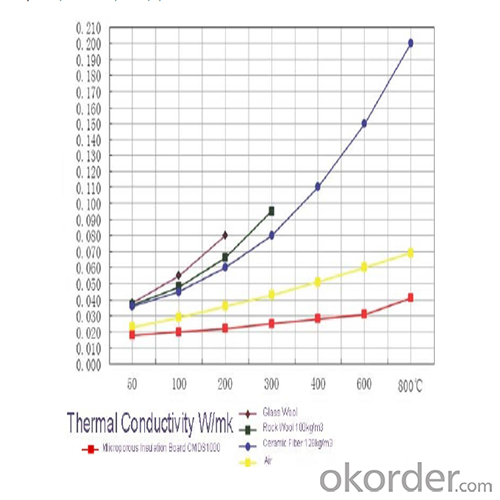

Extremely low thermal conductivity

High thermal stability

High compressive strength

No harmful respirable fibres

Free of organic binders

Environmentally friendly

Resistant to most chemicals

Non combustible

Easy to handle

Typical Applications

Back-up insulation in industrial furnaces

Fuel cells (SOFC)

Thermal Batteries

Aluminium industry ( launders,Smelter.etc. )

Glass & ceramics industry

Petrochemical industry (cracking furnace, reformer)

Black box & VDR (Voyage Data Recorder)

Data loggers

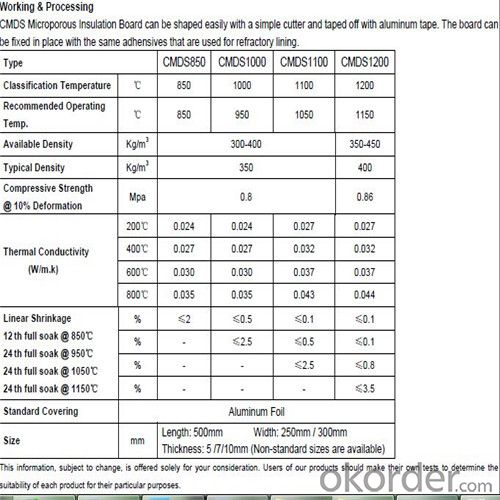

Working & Processing

M5100 can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Technical Data for for Micropore Insulation Board ,Heat Insulation materials

| Description | MISSION STD Panel M5100 | ||||

| Classification Temperature | 0C | 850 | 1000 | 1100/1100S | 1200/1200S |

| Long time Exposure | 850 | 950 | 1050/1000 | 1150/1100 | |

| Nominal Density | [kg/m3] | 260-280 | 260-280 | 400-450 | 450-550 |

| Typical Density | 280 | 280 | 450 | 500 | |

| Compression Strength | [MPa] | 0.32 | 0.32 | 0.72 | 0.8 |

| @10% deformation (ASTM C-165) | |||||

| Thermal Conductivity | |||||

| 200 0C | W/m.K | 0.022 | 0.022 | 0.024 0.028 | 0.027 0.029 |

| 400 0C | W/m.K | 0.025 | 0.025 | 0.028 0.032 | 0.032 0.035 |

| 600 0C | W/m.K | 0.028 | 0.028 | 0.032 0.038 | 0.037 0.042 |

| 800 0C | W/m.K | 0.033 | 0.033 | 0.035 0.045 | 0.043 0.046 |

| Specific Heat Capacity | |||||

| 200 0C | [KJ/Kg K] | 0.85 | 0.86 | 0.86 | 0.89 |

| 400 0C | [KJ/Kg K] | 0.95 | 0.96 | 0.97 | 0.99 |

| 600 0C | [KJ/Kg K] | 1.02 | 1.03 | 1.04 | 1.05 |

| 800 0C | [KJ/Kg K] | 1.07 | 1.08 | 1.08 | 1.08 |

| Linear Shrinkage | |||||

| 12h full soak @ 850 0C | % | ≤2 | ≤0.5 | ≤0.1 ≤0.1 | ≤0.1 ≤0.1 |

| 24h full soak @ 950 0C | - - - | ≤2.5 | ≤0.5 ≤0.1 | ≤0.5 ≤0.5 | |

| 24h full soak @ 1050 0C | - - - | - - - | ≤2.5 - - - | ≤2.5 ≤2.5 | |

| 24h full soak @ 1150 0C | - - - | - - - | - - - - - - | ≤3.5 - - - | |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: Can glass fiber textiles be used in automotive interiors?

- Yes, glass fiber textiles can be used in automotive interiors. Glass fiber textiles, also known as fiberglass textiles, are lightweight and have excellent strength-to-weight ratio, making them suitable for a variety of applications in the automotive industry. These textiles are commonly used for reinforcing composites and providing structural support in various parts of the vehicle, including interior components. Glass fiber textiles can be used for upholstery and lining materials, offering durability and resistance to wear and tear. They are also fire-resistant, making them a safer choice for automotive interiors. Additionally, glass fiber textiles can be molded into different shapes and sizes, allowing for customization and integration into various interior designs. Moreover, glass fiber textiles offer thermal and acoustic insulation properties, helping to improve the overall comfort and noise reduction inside the vehicle. They can be used as insulation liners in the doors, roof, and floor panels, contributing to a quieter and more comfortable driving experience. In conclusion, glass fiber textiles are a versatile and suitable material for automotive interiors due to their lightweight, strength, durability, fire resistance, customization options, and insulation properties. Their use in automotive interiors helps enhance the overall quality, safety, and comfort of the vehicle.

- Q: Are glass fiber textiles lightweight?

- Glass fiber textiles, known for their lightweight quality, are made by weaving together extremely thin strands of glass. This results in a textile with low density and a high strength-to-weight ratio. Consequently, they are ideal for industries like aerospace, sports, and automotive, where lightweight materials are necessary. Furthermore, the lightweight attribute of glass fiber textiles makes them easy to handle and install.

- Q: Are glass fiber textiles resistant to chemicals?

- Yes, glass fiber textiles are generally resistant to chemicals.

- Q: Can glass fiber textiles be printed?

- Yes, glass fiber textiles can be printed. The printing process typically involves using specialized inks or dyes that adhere to the glass fibers, allowing for various designs or patterns to be applied to the textile.

- Q: How about the alkali fiberglass and alkali free fiberglass?

- Fabric has a high demand for cloth, especially electronic cloth, and the thickness of the fabric,

- Q: Can glass fiber textiles be used in tents or camping equipment?

- Glass fiber textiles, commonly referred to as fiberglass, find extensive applications in tents and camping equipment owing to their robustness, resilience, and ability to withstand harsh weather conditions. These textiles serve multiple purposes including tent poles, tent fabrics, as well as other camping gear like backpack frames, sleeping bag poles, and lightweight furniture. By incorporating glass fiber textiles, tents and camping equipment achieve remarkable stability, flexibility, and longevity, rendering them a favored option among individuals who enjoy outdoor activities.

- Q: How do glass fiber textiles compare to other types of textiles?

- Fiberglass textiles, also called glass fiber textiles, possess distinct characteristics that differentiate them from other textile types. Firstly, their strength and durability are remarkable. They boast a high tensile strength, enabling them to endure significant pulling force without breaking. Consequently, they prove ideal for applications prioritizing strength and durability, such as constructing buildings or manufacturing industrial products. Secondly, these textiles exhibit exceptional resistance to heat and fire. Unlike numerous textile types, they do not readily burn or melt when exposed to high temperatures. This fire-resistant quality renders them suitable for environments where fire safety is a concern, such as manufacturing protective clothing or constructing fire-resistant barriers. Moreover, glass fiber textiles possess exemplary electrical insulation properties. They do not conduct electricity, making them perfect for electrical applications necessitating insulation, like producing electrical cables or constructing electrical equipment. Additionally, glass fiber textiles resist chemical corrosion. They do not easily react with acids, alkalis, or other corrosive substances, making them suitable for environments emphasizing chemical resistance, such as manufacturing chemical storage tanks or constructing chemical processing plants. However, glass fiber textiles also have certain limitations. They can be relatively rigid and may lack the softness and flexibility of natural or synthetic fibers. Additionally, they can be more costly compared to other textile types, limiting their application possibilities. In summary, glass fiber textiles offer exceptional strength, heat resistance, electrical insulation, and chemical resistance properties. Despite their limitations, their unique properties make them a valuable choice for various industrial applications where durability and performance are essential.

- Q: Can glass fiber textile be used in insulation?

- Yes, glass fiber textile can be used in insulation. It is commonly used in the construction industry for thermal and acoustic insulation purposes due to its excellent insulation properties and fire resistance.

- Q: Can glass fiber textiles be used in reinforcement of glass composites?

- Yes, glass fiber textiles can be used in the reinforcement of glass composites. Glass fiber textiles possess high strength and stiffness, making them ideal for enhancing the mechanical properties of glass composites. They can be incorporated into the composite matrix to improve its tensile, flexural, and impact strength, as well as increase its resistance to cracks and fractures. Overall, glass fiber textiles offer significant reinforcement capabilities for glass composites.

- Q: Can glass fiber textiles be used for making outdoor furniture?

- Yes, glass fiber textiles can be used for making outdoor furniture. Glass fiber textiles are known for their durability, strength, and resistance to weather elements such as moisture, UV rays, and extreme temperatures. These properties make them suitable for outdoor applications, including furniture. Glass fiber textiles are often used in the manufacturing of outdoor furniture due to their ability to withstand various weather conditions without deteriorating or losing their structural integrity. Additionally, glass fiber textiles can be molded into different shapes and designs, allowing for versatile and aesthetically pleasing outdoor furniture options. Overall, glass fiber textiles are a viable choice for making outdoor furniture due to their durability and ability to withstand outdoor conditions.

Send your message to us

Glass Fiber Textile Reinforced Microporous Insulation Board for Ladle Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords