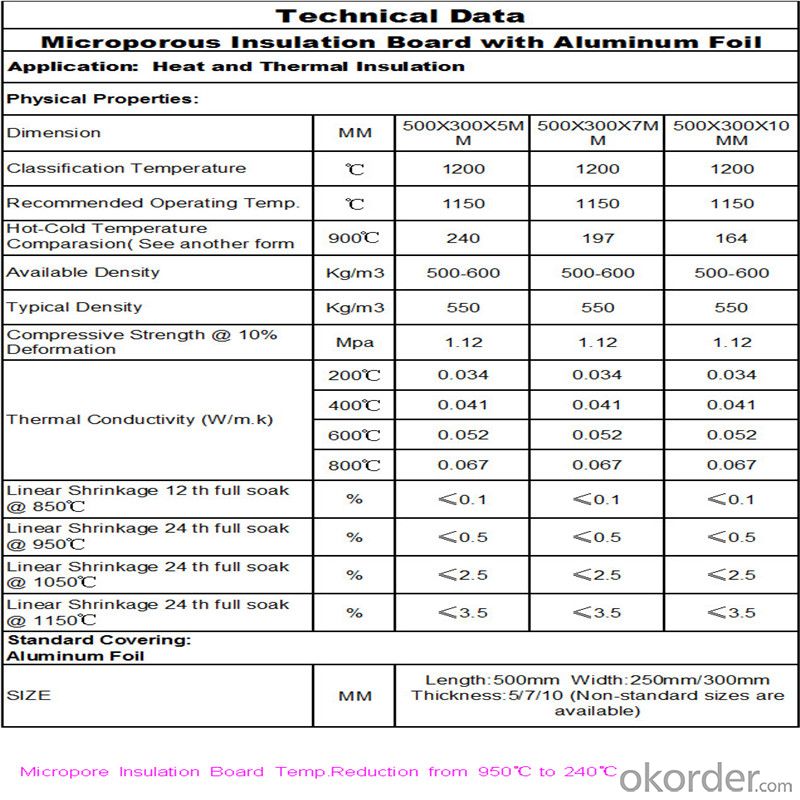

VIP Boards Insulation Layer with Microporous Insulation Boards - Ladle Furnace Temperature Reduction from 950℃ to 240℃

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation Layer Using Microporous Insulation Boards in Ladle Furnace Reduction From 950℃ to 240℃

Product Description for Insulation Layer Using Microporous Insulation Boards

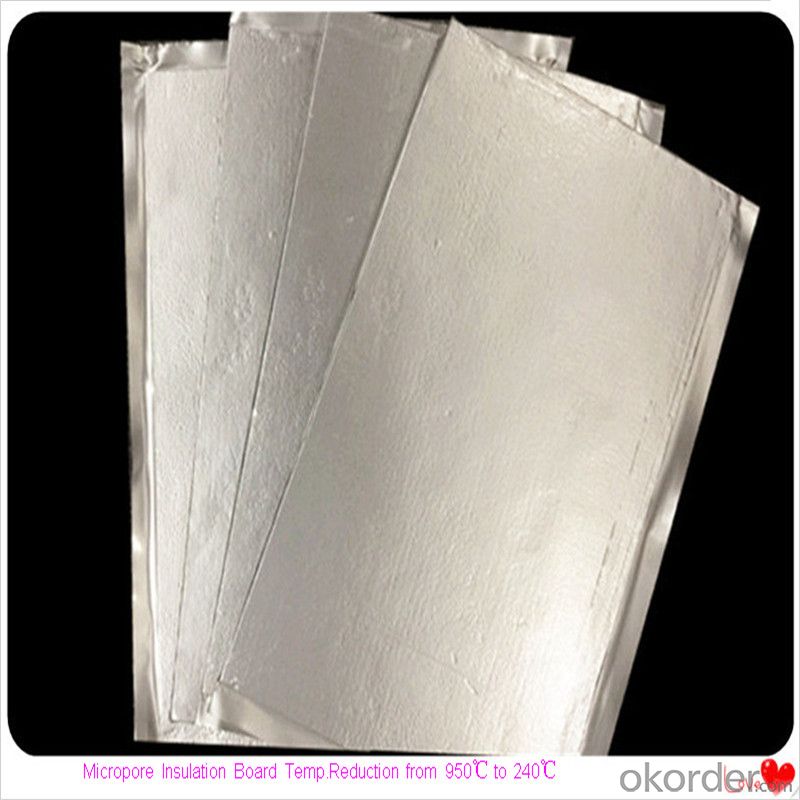

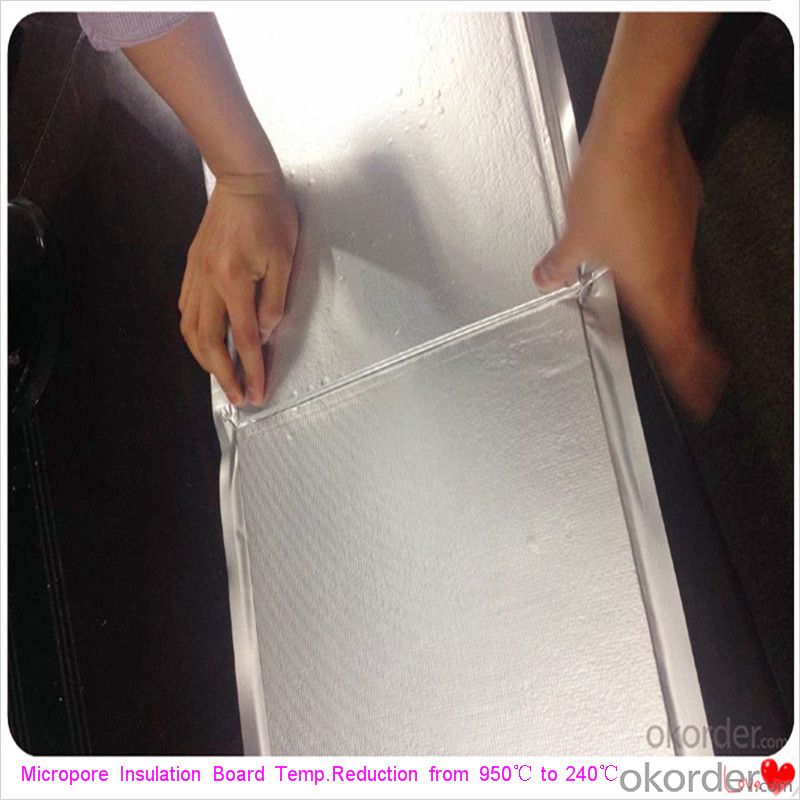

CMDS Microporous Insulation Boards are specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous insulation boards when moisture may occur due to castables, mortar etc.

Micropore Insulation Boards can be as much as four times more effective than conventional insulation materials. In practical terms this means that a Micropore Insulation Boards system can be only one quarter of the thickness for equivalent thermal control. This becomes crucially important wherever space is limited.

Structure& Advantage for Insulation Layer Using Microporous Insulation Boards

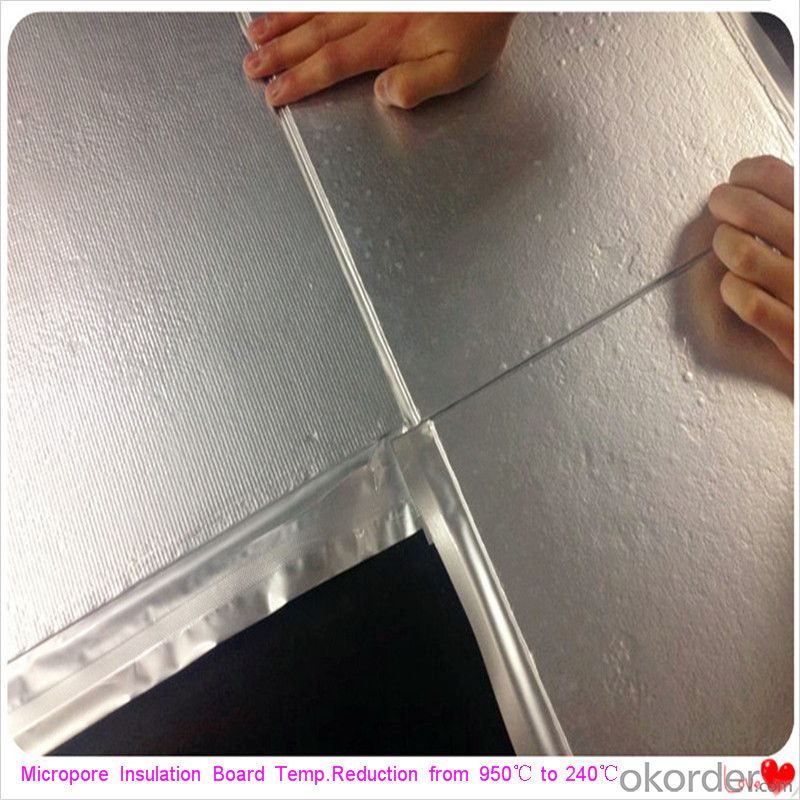

for Micropore/ Microporous Insulation Boards with Alumina Foil Cover

1) Extremely low thermal conductivity

2)High compressive strength

3)High thermal stability

4) Environment protection

5) High thermal stability

6) Environment protection

7) Easy to handle

8) No harmful inhalable fibers

9) Resist most chemical attacks

10) Free of organic binders

We Are The Major Suppiler for

Using our Micropore/ Microporous Insulation Boards with alumina foil cover

Allied Mineral Products,inc

Refractories Incorporated

SRS Sorg Refractory Systems GmbH, (Germany)

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

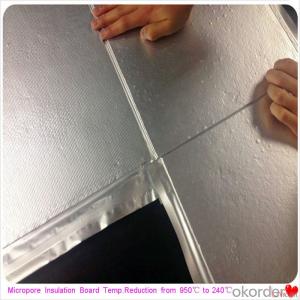

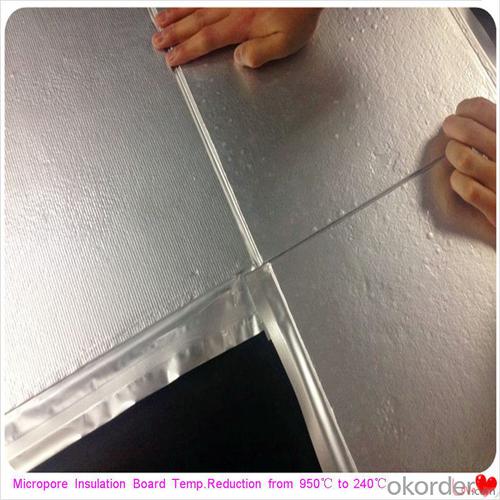

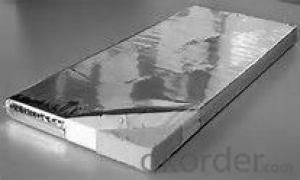

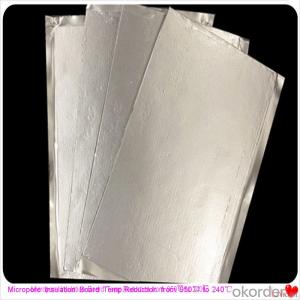

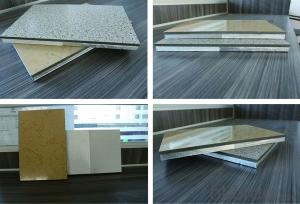

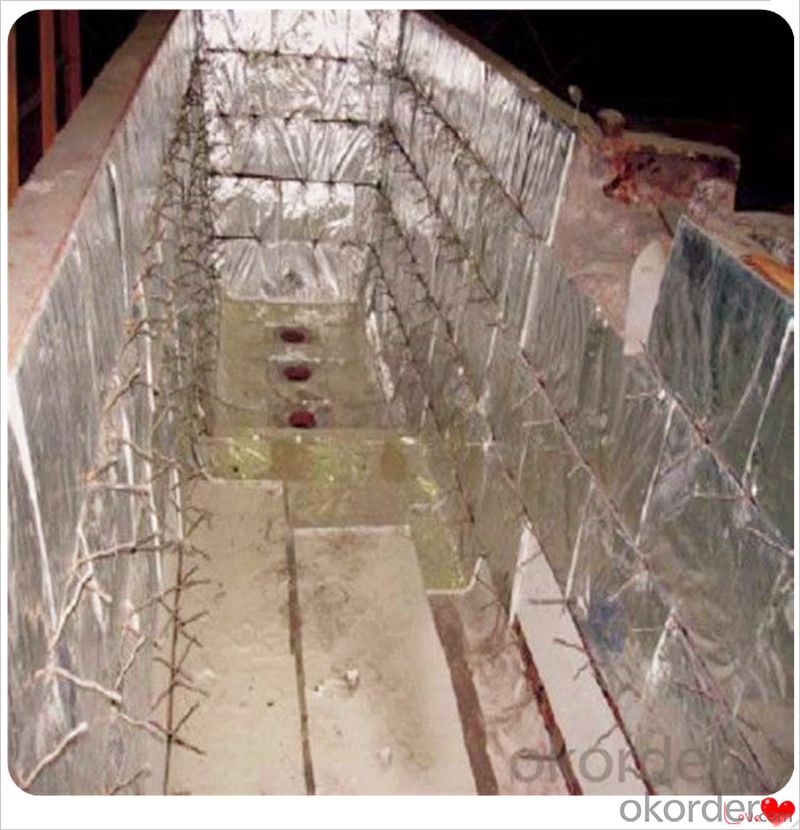

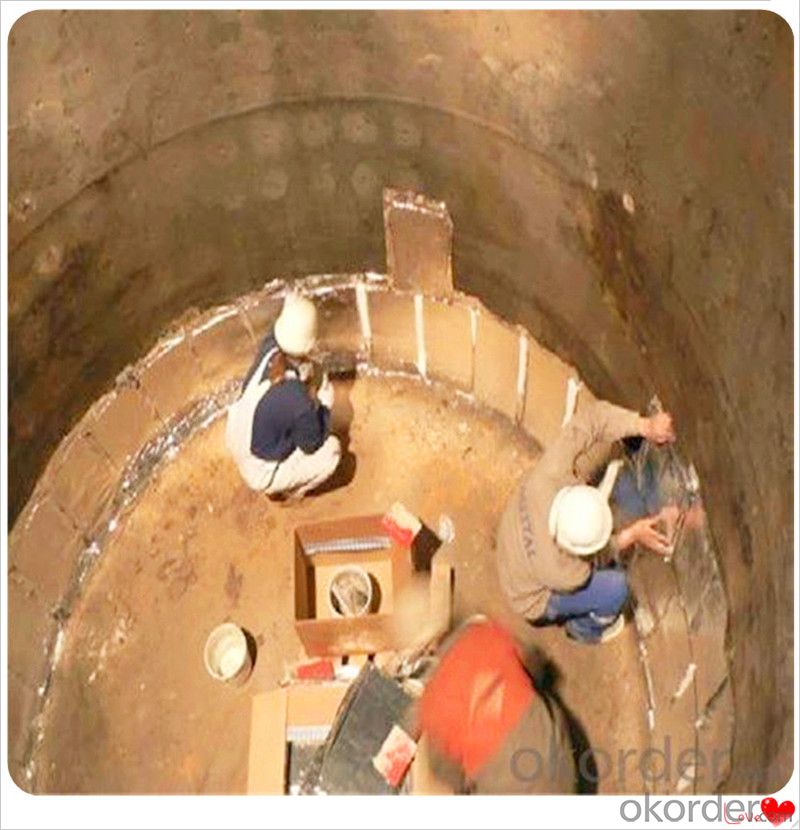

Major Images for Insulation Layer Using Microporous Insulation Boards

Packaging & Delivery for Insulation Layer Using Microporous Insulation Boards

Package:each pallet size1100 x 1300 x 1200mm, and packing with plastic foil or case. usually use plastic foil.

Application Images for Microporous Insulation Boards

Specification Data for Microporous Insulation Boards

FAQ

Q1:Are you a manufacturer or trader?

A:Manufacturer+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different Micropore/ Microporous Insulation Boards is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services in 24 hours!!

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- At present, the domestic brand is not clear who is using a good insulation board should be made of silica filler, because the BET for the nano-so the effect is better. Energy saving can reach more than 30 percent

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- This place is different in different places, the calculation is not the same. We are here so: independent columns need to calculate the scaffolding to (peripheral circumference +3.6) multiplied by the column height calculation, 3.6 meters below the single row of scaffolding, 3.6 meters above the corresponding height of the double row. With the overall beam of the beam does not calculate the scaffolding. You say the frame column, to distinguish between different situations.

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q: What is the best insulation material? To be waterproof.

- Specifications are generally diameter of 48mm wall thickness of 3.5mm; diameter of the bones of the fen fen shed leters light dog 51 degrees wall thickness of 3.0mm these two kinds of market is currently the country is almost 3900 yuan / ton buckle according to sets of about 5 yuan / set

- Q: External wall insulation material which is good, external wall insulation materials

- Advertisement is here! In fact, the so-called fresh air ventilator is a conceptual product. Ventilation function is very limited, that is difficult to achieve the effect of exchange air. As to say that the answer is more efficient and nonsense. Said the ventilation is limited, because of its small import and export, the amount of ventilation at the end. At the same time the indoor outlet can not guarantee the dirty air away. Said the heat exchange, you can imagine, indoor and outdoor air temperature difference will be more than ten degrees only in a small exchange area and a very short exchange time, in order to replace the hot air into the indoor temperature near the cold air , There is no material to do now.

Send your message to us

VIP Boards Insulation Layer with Microporous Insulation Boards - Ladle Furnace Temperature Reduction from 950℃ to 240℃

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords