GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

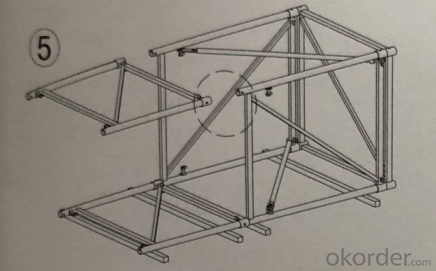

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

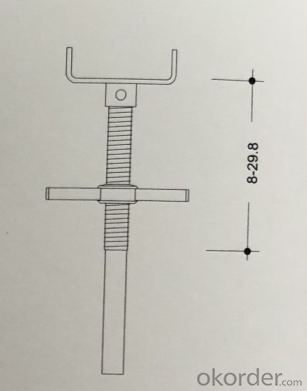

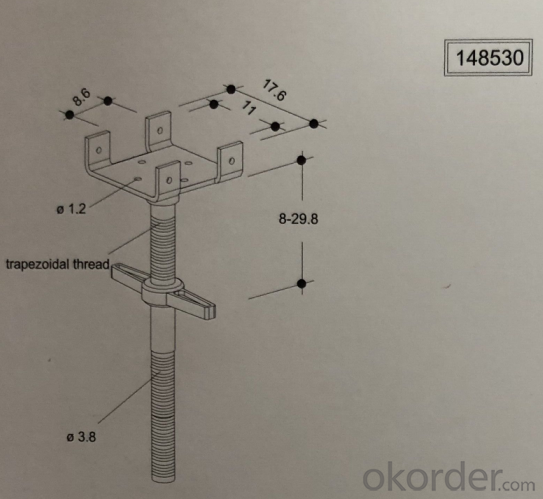

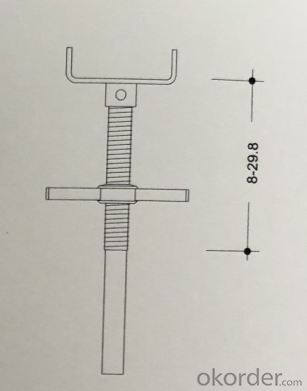

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

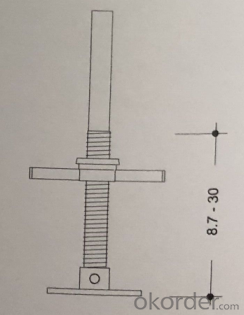

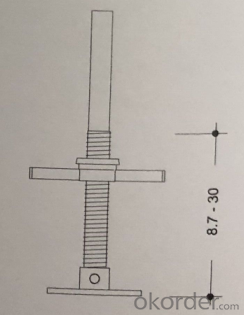

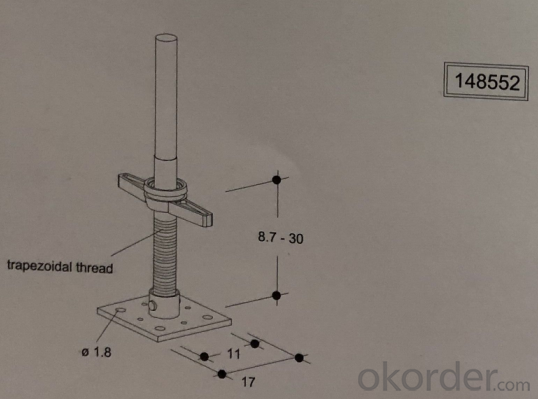

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

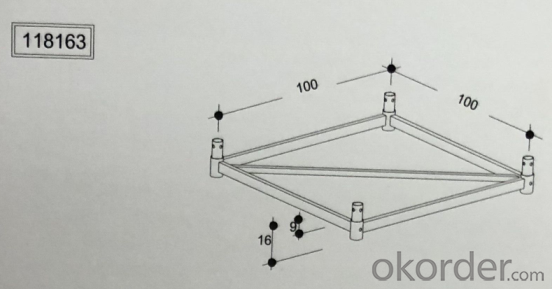

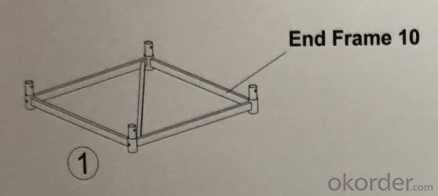

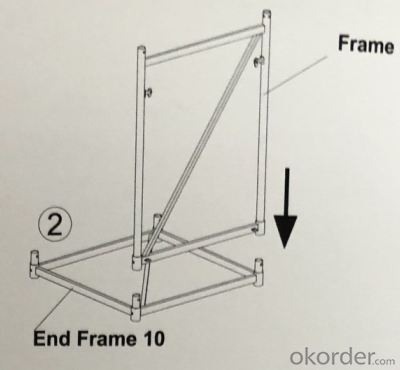

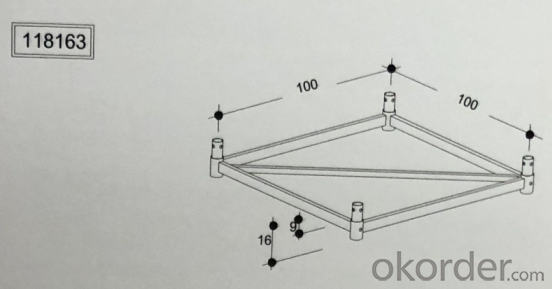

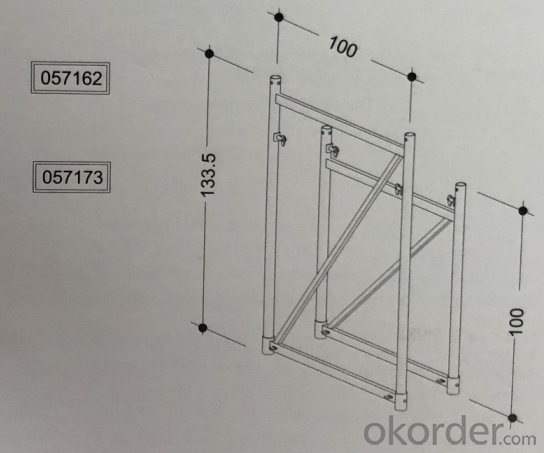

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

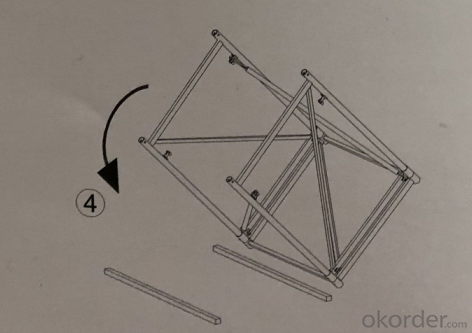

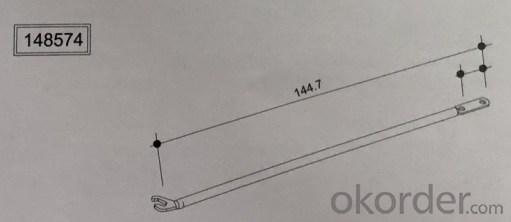

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q: What are the requirements for acceptance of steel support

- What are the requirements for acceptance of steel supportAcceptance criteria for BRB product, only in China's 2010 version of "code for seismic design of buildings" (GB 50011-2010) and "technical specification for steel structure of tall buildings" (JGJ99-2010) manuscript has been mentioned, but the standard is still low:

- Q: What is the weight of a standard steel prop?

- The weight of a standard steel prop can vary depending on its size and specifications. On average, a typical steel prop can weigh around 25 to 30 pounds.

- Q: What are the potential aesthetic considerations when using steel props?

- When using steel props, potential aesthetic considerations include the visual appearance of the props themselves, their compatibility with the surrounding environment or design, and the overall impact they may have on the aesthetic appeal of the space. Additionally, the choice of finishes, colors, or textures of the steel props can also play a role in their overall aesthetic integration.

- Q: How do you check the stability and integrity of a steel prop?

- To check the stability and integrity of a steel prop, several steps can be followed. Firstly, conduct a visual inspection to look for any signs of damage, such as cracks, dents, or deformities. Secondly, ensure that all connections and fasteners are secure and not loose. Thirdly, use a level to check if the prop is plumb and not leaning. Additionally, verify that the prop is properly braced and supported, ensuring it has adequate load-bearing capacity. Finally, conduct load testing if necessary, applying incremental weight to assess the prop's stability.

- Q: Can steel props be used in temporary shoring applications?

- Yes, steel props can be used in temporary shoring applications. Steel props are strong and sturdy, making them ideal for supporting loads and providing temporary support in construction projects. They are adjustable in height and can be easily installed, making them a reliable choice for temporary shoring applications.

- Q: Can steel props be used for temporary support during tank installation?

- Steel props are indeed capable of offering temporary support during tank installation. They are frequently employed in construction to provide temporary support to structures like walls, ceilings, and floors. These props can be effortlessly adjusted to the desired height and are easily installed and removed, thereby making them an optimal choice for temporary purposes. In the case of tank installation, steel props can be utilized to offer supplementary support, thereby ensuring stability and security throughout the installation procedure. Nonetheless, it is crucial to have professionals properly design and install the steel props to guarantee the safety of the installation process.

- Q: Can steel props be used in the installation of heavy machinery?

- Yes, steel props can be used in the installation of heavy machinery. Steel props, also known as steel support systems or steel shores, are commonly used to provide temporary support during construction or installation processes. They are designed to withstand heavy loads and provide stability, making them suitable for supporting heavy machinery during installation. Steel props can be easily adjusted to the desired height and provide reliable support, ensuring the safety of both the machinery and the workers involved in the installation process. Additionally, steel props are durable and can be reused for future installations, making them a cost-effective solution.

- Q: Can steel props be used for supporting temporary stages for concerts?

- Yes, steel props can be used for supporting temporary stages for concerts. Steel props are strong, durable, and can withstand the weight and load requirements of a temporary stage. They provide stability and support, ensuring the safety of the performers and audience during the concert.

- Q: Are steel props suitable for use in tunnel construction?

- Yes, steel props are suitable for use in tunnel construction.

- Q: How is a steel prop used in construction?

- A steel prop, also known as an adjustable steel prop or adjustable steel shore, is a tool commonly used in construction to support temporary structures or provide temporary support to existing structures during construction or renovation activities. Steel props are typically made of high-quality steel and are telescopic in nature, meaning they can be adjusted to various lengths as per the specific requirements of the construction project. They consist of an outer tube with multiple holes and an inner tube that fits inside the outer tube, allowing for height adjustments. The primary purpose of a steel prop is to provide vertical support, stability, and load-bearing capacity. They are often used to support horizontal beams, ceilings, slabs, formwork, and other temporary structures. Steel props can be used in a variety of construction scenarios, including residential, commercial, and industrial projects. The process of using a steel prop involves placing the prop vertically underneath the structure that requires support. The height of the prop is then adjusted by extending or retracting the inner tube and securing it in place using a locking mechanism or a pin. This allows the prop to bear the weight of the structure and provide the necessary support. Steel props are designed to withstand heavy loads and provide stability, making them a reliable choice in construction projects where temporary support is required. They are known for their durability, versatility, and ease of use. Additionally, their adjustable nature allows for flexibility in adapting to different heights, making them suitable for a wide range of applications. In conclusion, a steel prop is a crucial tool in construction, providing temporary support and stability to structures during construction or renovation activities. Its adjustable design and load-bearing capacity make it an essential component in various construction projects, ensuring safety and efficiency throughout the construction process.

Send your message to us

GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords