Germany standard D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

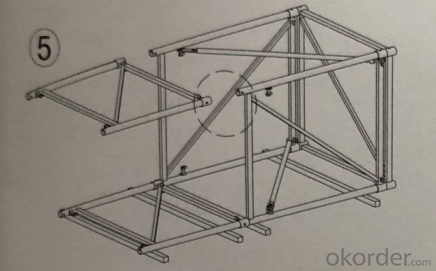

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

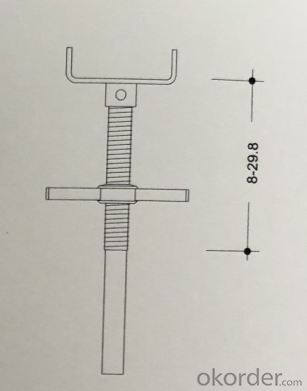

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

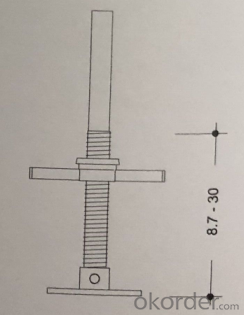

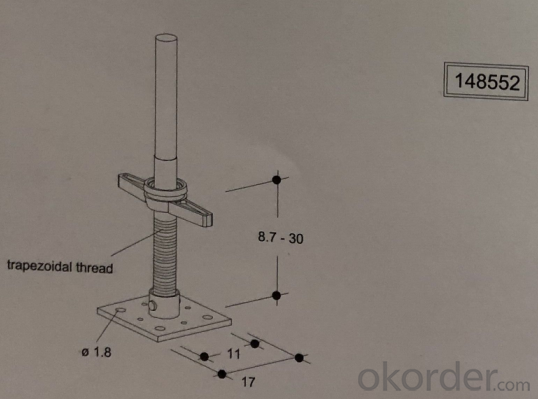

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

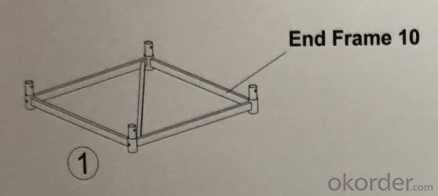

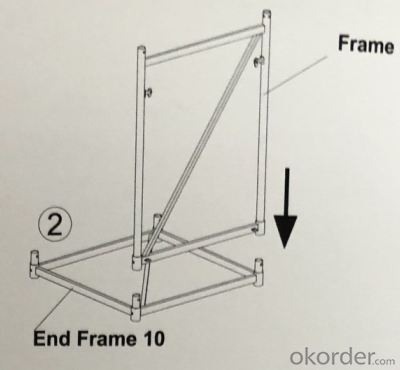

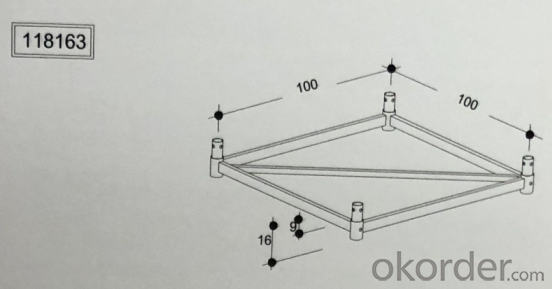

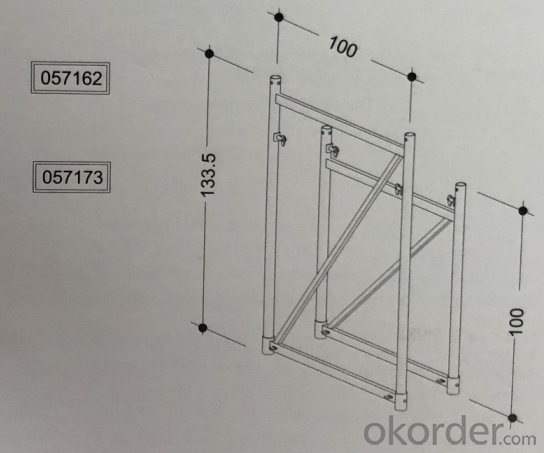

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

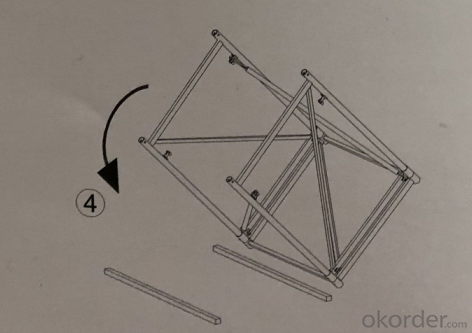

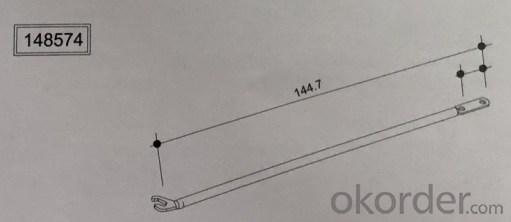

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q: How is the load capacity of a steel prop determined?

- The load capacity of a steel prop depends on several factors that consider the properties of the material and the design specifications. Firstly, the load capacity is affected by the type and grade of steel utilized in the prop. Steel props are commonly manufactured using high-strength, low-alloy steels that can withstand heavy loads. The properties of the steel, such as its yield strength, ultimate tensile strength, and elongation, play a significant role in determining the load capacity. Additionally, the load capacity is determined by the design specifications of the prop, including its dimensions, shape, and reinforcement. The length, diameter, and wall thickness of the prop impact its ability to resist bending and compression, which directly affects the load-bearing capacity. Moreover, features like internal ribs or flanges can improve the strength and stability of the prop, thus increasing its load capacity. Furthermore, the load capacity is influenced by the distribution of the load and the method of support. Steel props are commonly employed in construction to support vertical loads, such as beams or slabs. The load capacity is calculated based on the maximum load that the prop can endure while maintaining stability and structural integrity. To determine the load capacity, engineers conduct various tests, such as compression tests, bending tests, or load deflection tests. These tests measure the performance of the steel prop under different load conditions and provide valuable data for determining the safe working load and ultimate load capacity. In conclusion, accurately determining the load capacity of a steel prop is crucial to ensure the safety and stability of the supported structure. This is achieved by considering the material properties, design specifications, and conducting performance tests.

- Q: How do you ensure stability when using multiple steel props?

- When using multiple steel props, there are several measures that can be taken to ensure stability: 1. Proper placement and spacing: The steel props should be placed at regular intervals along the structure or area that requires support. The spacing between the props should be determined based on the load-bearing capacity of each prop and the weight of the structure being supported. Adequate spacing ensures that the load is evenly distributed among the props, reducing the risk of overloading any one prop. 2. Secure fixing: Each steel prop should be securely fixed at both ends to ensure stability. This can be achieved by using appropriate attachments or fittings that provide a firm connection between the prop and the structure it supports. It is important to ensure that the fixing mechanism is strong enough to withstand the weight and forces exerted on the prop. 3. Regular inspections: Regular inspections of the steel props are essential to identify any signs of damage or weakness. This includes checking for cracks, deformities, or loose fittings. Any damaged or compromised props should be immediately replaced to maintain stability. 4. Adequate bracing: Bracing is essential to provide additional support and prevent lateral movement of the steel props. Bracing can be achieved by using diagonal supports or cross-bracing between the props. This helps to distribute the load more evenly and enhance overall stability. 5. Load distribution: Proper load distribution is crucial when using multiple steel props. It is important to calculate and distribute the load based on the load-bearing capacity of each prop. This can be achieved by using load distribution plates or spreader beams that help evenly distribute the load across multiple props. 6. Consideration of external factors: External factors such as wind, vibrations, or uneven ground conditions can affect the stability of the steel props. It is crucial to consider these factors during the design and placement of the props. Additional measures such as wind bracing or reinforcing the ground may be required to maintain stability under such conditions. Overall, ensuring stability when using multiple steel props requires careful planning, proper placement, secure fixing, regular inspections, adequate bracing, and consideration of external factors. By following these measures, the risk of instability and potential accidents can be significantly reduced.

- Q: What are the standard sizes of steel props?

- The standard sizes of steel props vary depending on the specific requirements of construction projects. However, there are common sizes that are widely used in the industry. These sizes typically range from 0.5 meters to 5 meters in length, with adjustable height options. The diameters of steel props can vary as well, but commonly range from 40mm to 60mm. It is important to note that the specific sizes of steel props may differ based on the load-bearing capacity needed for each project. Therefore, it is crucial to consult engineering and construction standards to determine the appropriate size of steel props for a given application.

- Q: What are the typical load testing procedures for steel props?

- The load testing procedures for steel props typically encompass the following stages: 1. Initial inspection: Before commencing load testing, it is essential to conduct a thorough examination of the steel props to detect any signs of damage or wear. This entails inspecting for cracks, deformations, corrosion, and other structural issues that may jeopardize the props' integrity. 2. Load calculation: The load testing procedure initiates with the determination of the maximum load capacity that the steel props are designed to withstand. This calculation considers variables such as prop type, dimensions, material strength, and relevant safety codes or standards. 3. Test setup: Once the load calculation is finalized, the subsequent step involves arranging the testing environment. This necessitates securely positioning the props and ensuring proper support to prevent any inadvertent collapse or movement during the test. 4. Load application: Hydraulic jacks, weights, or other suitable equipment are employed to gradually apply load to the steel props. The load is incrementally increased until it reaches the predetermined maximum load specified in the load calculation. 5. Load measurement: Throughout the testing process, precise load measurements are taken at regular intervals to monitor the behavior of the steel props. This encompasses measuring the load distribution across the props and any deflection or displacement that may transpire. 6. Testing duration: Typically, the load is maintained for a specific duration to allow for observation and assessment of the props' performance under sustained load conditions. The duration may vary depending on the specific requirements and standards applicable to the props being tested. 7. Result assessment: Upon completion of the load testing, the collected data and observations are analyzed to evaluate the performance of the steel props. This entails assessing factors such as deflection, stability, and structural integrity, as well as comparing the test results against applicable safety standards or regulations. 8. Report generation: A comprehensive report is usually prepared, documenting the load testing procedures, results, and any relevant observations or recommendations. This report serves as a record of the testing process and provides valuable information for decision-making concerning the use and safety of the steel props.

- Q: How do you protect steel props from damage during construction activities?

- There are various measures that can be implemented to safeguard steel props from harm during construction activities: 1. Optimal storage: Allocate a specific area for storing steel props that shields them from external elements like rain, snow, and direct sunlight. This will avert corrosion and other types of damage. 2. Routine maintenance: Regularly examine the props for signs of deterioration. Promptly replace any impaired or weakened components to avoid structural failure during construction. 3. Utilize protective covers: When not in use, cover the steel props with caps or covers to shield them from dust, debris, and potential sources of harm. 4. Handle with caution: Train construction workers in proper handling techniques to prevent accidental harm. Refrain from dropping or throwing the props, and employ suitable lifting equipment when necessary. 5. Avoid overburdening: Ensure that the steel props are not exposed to excessive weight or loads that surpass their specified capacity. This will prevent structural failure and damage to the props. 6. Employ appropriate support: When utilizing the steel props to support structures, guarantee that they are correctly aligned and supported by adequate foundations or bases. This will distribute the load evenly and diminish the risk of damage. 7. Regular inspections: Conduct periodic inspections of the steel props throughout the construction process to detect any potential issues. This will enable timely repairs or replacements, ensuring the props remain in good condition. By adhering to these guidelines, construction activities can be executed safely, and the steel props can be shielded from harm, thereby ensuring their durability and effectiveness.

- Q: What are the primary materials used in manufacturing steel props?

- Steel is the main material employed in the production of steel props, as one would expect. To guarantee the props possess the required strength and durability for their intended use, high-quality steel alloys are specifically utilized. These alloys may consist of elements such as carbon, manganese, silicon, and diverse trace elements to attain the desired characteristics. Furthermore, rubber or plastic materials might be employed for specific components or accessories of the steel props, such as grip handles or protective caps. However, the primary composition of the steel props revolves around steel itself.

- Q: Can steel props be used to support formwork?

- Yes, steel props can be used to support formwork. Steel props are adjustable telescopic devices that are commonly used to support formwork during construction. They are designed to provide vertical support and stability to the formwork structure, ensuring that it can safely hold the weight of the concrete being poured. Steel props are preferred for formwork support due to their strength, durability, and adjustability, allowing for easy installation and removal. They are also versatile and can be used in a variety of construction applications, including supporting slabs, beams, walls, and columns. Overall, steel props are an effective and reliable choice for supporting formwork during construction projects.

- Q: Are steel props suitable for supporting temporary bridges or walkways over water bodies?

- Yes, steel props are suitable for supporting temporary bridges or walkways over water bodies. Steel is a strong and durable material that can withstand the weight and pressure exerted by people or vehicles on temporary structures. It provides stability, ensuring the safety and integrity of the bridge or walkway. Additionally, steel props can be easily adjusted and secured in place, making them ideal for temporary installations over water bodies.

- Q: How do you dismantle steel props?

- To dismantle steel props, you will typically need to follow these steps: 1. Begin by identifying the type of steel prop you are working with, as different props may have different assembly mechanisms. 2. Remove any locking pins or safety devices securing the prop in place. These are usually located near the adjustable sections of the prop. 3. Loosen the adjustment mechanism of the prop, whether it's a threaded screw or a lever system. This will allow you to decrease the length of the prop and make it easier to dismantle. 4. Carefully slide the prop apart by pulling the sections away from each other. Be cautious of any potential springs or tension that may be present in some props. 5. If the prop has multiple telescopic sections, you may need to repeat step 4 for each section until the prop is fully disassembled. 6. Once the prop is fully dismantled, ensure all parts are clean and free from dirt or debris. Store them properly to prevent damage or loss. Remember to always refer to the manufacturer's instructions or seek professional advice if you are unsure about dismantling a specific type of steel prop.

- Q: What are the different footplate options available for steel props?

- Some of the different footplate options available for steel props include standard flat footplates, adjustable footplates, and swivel footplates. These options allow for increased stability and flexibility when supporting temporary structures or scaffolding.

Send your message to us

Germany standard D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords