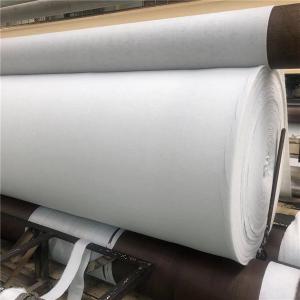

Geotextiles Sub - Various Non-Woven Geotextile for Construction

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 999999 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We provide various parameters and types of geotextiles, including filament non-woven geotextile, Non Woven Polypropylene Geotextile, staple geotextile, needle punched non-woven geotextile, polypropylene non-woven geotextile, inverted filter geotextile, woven geotextile, curing geotextile, etc. We have a variety of standard specifications of geotextiles, and can also provide you with specific specifications of geotextile production. If you want to purchase, we will provide samples and mail them to you, and finally we will supply for you at the wholesale price of the manufacturer. Because different parameters have different prices, if you want to know the detailed parameters and prices, please contact us to obtain the sample book.

Product specification: 100g/㎡~800g/㎡

Package specification: 1 m-7 m wide; Length: 50m-100m (according to customer requirements)

What is geotextile?

Geotextiles, also known as geotextiles, are permeable geosynthetics made of synthetic fibers through needle punching or weaving. Geotextile is one of the new geosynthetics. The finished product is cloth, generally 4-6 meters wide and 50-100 meters long. Geotextiles are divided into woven geotextiles and non-woven filament geotextiles.

Characteristics of geotextile

1. High strength, due to the use of plastic fiber, it can maintain full strength and elongation under dry and wet conditions.

2. Corrosion resistance. It can resist corrosion for a long time in soil and water with different pH values.

3. Water permeability is good because there are gaps between fibers, so it has good water permeability.

4. Good anti microbial property will not damage microorganisms and insects.

5. The construction is convenient. Because the material is light and soft, the transportation, laying and construction are convenient.

6. Complete specifications: width up to 9 meters. It is the widest product in China, and the mass per unit area is 100-1000g/m2.

Use of geotextile

It is widely used in water conservancy, electric power, mine, highway, railway and other geotechnical projects:

l. Filter material separated by soil layer;

2. Drainage materials for mineral processing of reservoirs and mines, and drainage materials for foundation of high-rise buildings;

3. Anti scour materials for river dams and slope protection;

4. Reinforcing materials for subgrade of railway, highway and airport runways, and reinforcing materials for road construction in marshland;

5. Frost and frost resistant thermal insulation materials;

6. Anti cracking materials for asphalt pavement.

Application field of geotextile

l. It is used as reinforcement in the backfilling of retaining wall or for anchoring the panel of retaining wall. Build wrapped retaining wall or abutment.

2. Reinforce the flexible pavement, repair the cracks on the road, and prevent the pavement from reflecting cracks.

3. Increase the stability of gravel slope and reinforced soil to prevent water and soil loss and frost damage of soil mass at low temperature.

4. The isolation layer between ballast and subgrade, or between subgrade and soft foundation.

5. The isolation layer between artificial fill, rockfill or material yard and foundation, and the isolation between different frozen soil layers. Filtration and reinforcement.

6. The filter layer of the upstream dam surface at the initial stage of the ash storage dam or tailings dam, and the filter layer of the drainage system in the backfill soil of the retaining wall.

7. Filter layer around the drainage pipe or gravel drainage ditch.

8. The filter layer of water well, relief well or baroclinic pipe in hydraulic engineering.

9. The geotextile isolation layer between the highway, airport, railway road and artificial rockfill and the foundation.

10. The earth dam is drained vertically or horizontally and buried in the soil to dissipate the pore water pressure.

11. The drainage behind the impervious geomembrane or under the concrete cover in the earth dam or earth embankment.

12. The seepage around the tunnel shall be eliminated to reduce the external water pressure on the lining and the seepage around the buildings.

13. Drainage of artificial fill ground sports ground.

14. Roads (including temporary roads), railways, embankments, earth rock dams, airports, sports grounds and other projects are used to strengthen soft foundations.

Classification of geotextiles

Short fiber needle punched nonwoven geotextile can be divided into polyester, polypropylene, nylon, vinylon, ethylene and other needle punched nonwoven geotextiles according to raw materials; It can be divided into ordinary type and composite type according to structure. The varieties of staple fiber needle punched nonwoven geotextiles are designed by the production department according to the market demand.

Laying method of geotextile

1. Manual roll paving shall be used, and the cloth surface shall be flat with appropriate deformation allowance.

2. The installation of filament or staple geotextile usually adopts several methods, such as lapping, stitching and welding. The width of stitching and welding is generally more than 0.1m, and the lap width is generally more than 0.2m. Geotextiles that may be exposed for a long time shall be welded or stitched.

3. Sewing of geotextile: All sewing must be continuous (for example, spot sewing is not allowed). The geotextile must overlap at least 150 mm before overlapping. The minimum distance between the needle and the selvage (the exposed edge of the material) shall be at least 25 mm. The sewn geotextile joint most includes one line of linear locking chain joint method. The suture used shall be a resin material with a minimum tension of more than 60N, and have the chemical corrosion resistance and ultraviolet resistance equivalent to or beyond that of geotextile. Any "missing needle" on the sewn geotextile must be re sewn at the affected place. Corresponding measures must be taken to prevent soil, particulate matter or foreign matter from entering the geotextile layer after installation.

4. During construction, the geotextile on the geomembrane shall be naturally lapped, and the geotextile on the upper layer of the geomembrane shall be welded by seam or hot air. Hot air welding is the preferred method for the connection of filament geotextile, that is, the hot air gun is used to heat the connection of two pieces of cloth at an instant of high temperature, so that their parts can reach the melting state, and a certain external force is immediately used to make them firmly bonded together. In the case that thermal bonding cannot be carried out in wet (rainy and snowy) weather, another method - suture connection method shall be adopted for geotextile, that is, special sewing machine shall be used for double suture connection, and chemical ultraviolet resistant suture shall be used. The minimum width is 10cm when sewing, 20cm when natural lapping and 20cm when hot air welding.

5. For the sewing, the suture with the same quality as the geotextile shall be used, and the suture shall be made of materials with stronger resistance to chemical damage and ultraviolet light.

6. After the geotextile is laid and approved by the site supervision engineer, the geomembrane can be laid.

7. The geotextile on the geomembrane is laid as above after the geomembrane is approved by Party A and the Supervisor.

8. The geotextile of each layer shall be numbered TN and BN.

9. The upper and lower layers of geotextile on the membrane shall be buried in the anchorage groove together with the geotextile.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geotextiles help in reducing the risk of landslides?

- Geotextiles help in reducing the risk of landslides by providing reinforcement and stabilization to soil slopes. They are placed within the ground to act as a barrier, preventing the movement of soil and reducing erosion. Geotextiles also improve drainage and promote the proper flow of water, reducing the build-up of excess moisture that can contribute to landslides. Overall, geotextiles play a crucial role in enhancing the stability and resilience of slopes, mitigating the risk of landslides.

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer numerous benefits in construction projects. Firstly, they provide effective soil stabilization by preventing erosion, reducing sedimentation, and enhancing soil strength. Secondly, they act as a barrier against weed growth, enhancing the aesthetics and longevity of the project. Additionally, geotextiles facilitate efficient drainage, preventing water accumulation and potential damage to structures. They also aid in separation and filtration, preventing the mixing of different materials and promoting the flow of water. Furthermore, geotextiles are cost-effective and easy to install, saving both time and labor. Overall, the use of geotextiles in construction projects improves durability, reduces maintenance needs, and ensures long-term sustainability.

- Q: How do geotextiles assist in slope stabilization?

- Geotextiles assist in slope stabilization by providing reinforcement and erosion control. They are placed on slopes to prevent soil erosion caused by water flow, thereby improving the overall stability of the slope. The geotextiles act as a barrier, preventing soil particles from being washed away while still allowing water to drain through. Additionally, they provide strength and reinforcement to the soil, reducing the risk of slope failure and landslides.

- Q: What are the different geotextile reinforcement techniques for slopes?

- There are several geotextile reinforcement techniques for slopes, including slope stabilization using geotextile wraps, slope reinforcement with geotextile grids, and slope erosion control using geotextile blankets. These techniques involve the use of geotextile materials to enhance the stability and performance of slopes, preventing erosion and promoting long-term stability.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in oil and gas industry applications. Geotextiles are commonly used for erosion control, soil stabilization, and filtration purposes in various industries, including the oil and gas industry. They can be used in applications such as pipeline construction, drilling operations, and containment systems. Geotextiles help to prevent soil erosion, provide stability for construction sites, and aid in filtration and separation of materials in oil and gas operations.

- Q: What are the factors to consider when installing geotextiles?

- When installing geotextiles, several factors need to be considered. These include the type and quality of the geotextile material, soil conditions, site preparation, proper installation techniques, and the intended purpose of the geotextiles. It is important to assess the site's drainage requirements, load-bearing capacity, and potential for erosion. Additionally, factors like climate, anticipated traffic loads, and environmental considerations should also be taken into account to ensure the successful installation and functionality of geotextiles.

- Q: How do geotextiles help in reducing the risk of soil liquefaction?

- Geotextiles help in reducing the risk of soil liquefaction by improving the stability and strength of the soil. They act as a barrier between the soil particles, preventing them from shifting and settling during seismic events. Additionally, geotextiles enhance the drainage properties of soil, allowing excess water to flow through and reducing the buildup of pore water pressure, which is a major cause of soil liquefaction.

- Q: What are the different weight options available for geotextiles?

- Geotextiles come in various weight options ranging from lightweight to heavyweight. The weight options typically available include 3-5 oz/sq.yd for lightweight, 6-8 oz/sq.yd for medium weight, and 10-16 oz/sq.yd for heavyweight geotextiles.

- Q: What are the standards and regulations governing geotextiles?

- Geotextiles are governed by various standards and regulations to ensure their quality, performance, and safety. Some of the key standards include ASTM D4355, which defines the classification system for geotextiles based on their functions and characteristics, and ASTM D4595, which specifies the test methods for determining the properties of geotextiles. Additionally, regulations such as the American Association of State Highway and Transportation Officials (AASHTO) and the Federal Highway Administration (FHWA) provide guidelines for the use of geotextiles in transportation projects. These standards and regulations aim to promote consistency, reliability, and effectiveness in the use of geotextiles for various applications.

- Q: Can geotextiles be used in groundwater protection systems?

- Yes, geotextiles can be used in groundwater protection systems. Geotextiles are permeable fabrics that can effectively filter and separate soil particles and other materials, preventing their migration into groundwater. They can be used as liners, barriers, or filters in various groundwater protection systems, such as landfills, ponds, and stormwater management systems, to enhance water quality and prevent contamination.

Send your message to us

Geotextiles Sub - Various Non-Woven Geotextile for Construction

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 999999 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords