Geotextile Vt Non Woven with 100% Virgin Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Nonwoven Geotextile

Geotextile Description

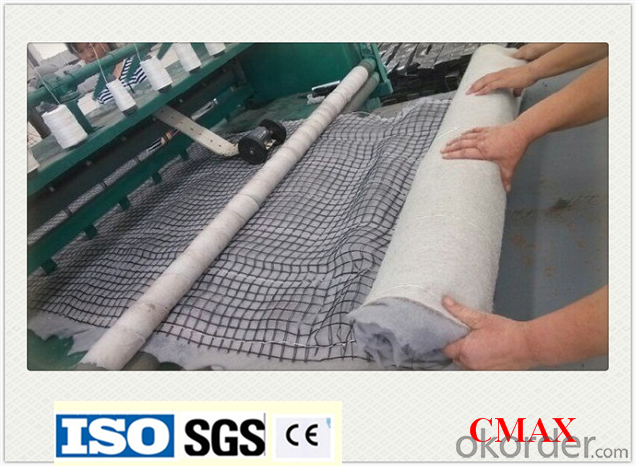

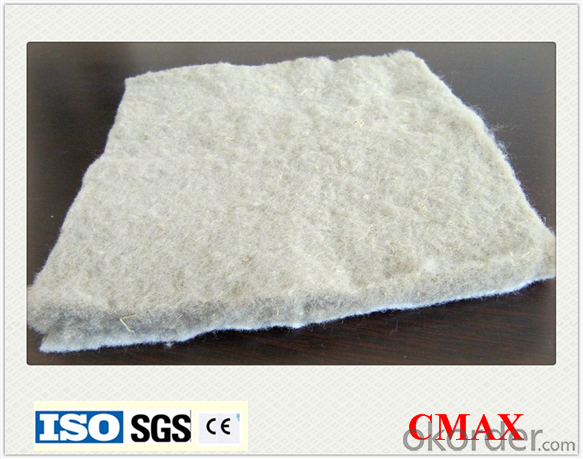

Filament yarn with polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the process of needle, also without heat treatment, is environmentally friendly building materials.Can replace the traditional engineering materials and construction methods, construction is more secure, and contribute to environmental protection, can be more economic, effective and lasting to solve basic problems in engineering construction.

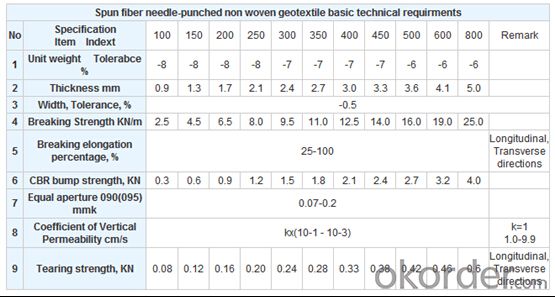

Geotextile Specification

Geotextile Property:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation.

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function.

Geotextile Application:

1. Water conservancy project and hydropower project.

2. Road paving, railway.

3. Airport and port.

4. River bank protection and tunnel

5. Environmental protection, etc.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are designed to be resistant to punctures and tears. They are made from durable materials that can withstand external forces and provide a high level of protection against damage.

- Q: Highway road crest u block below the geotextile roadway below the curb

- At present, the use of a curb stone molding machinery, prefabricated ratio can guarantee the strength of the mold release time, less water content, aggregate will segregate a large amount of water, mortar sticky mold

- Q: Geotextile packaging what are the requirements

- Geotextile packaging requirements are as follows: 1, staple acupuncture non-woven geotextile according to set into a long volume of packaging. The fixed length shall be determined in accordance with the product specification or the parties concerned. 2, the product of the splicing rate should be less than 15%, the total length of each piece of stitching products should be 7.1.1 fixed length plus 1m or more, every 100m to allow splicing 2, or by the supply and demand sides to determine. 3, the length of the product in the 30m below a small package can be a separate package, for a head treatment, 4, product packaging should ensure that no scattered, no damage, no pollution. Users have special requirements, the supply and demand sides to determine the consultation.

- Q: How do geotextiles help with reinforcement of geosynthetic tubes?

- Geotextiles help with reinforcement of geosynthetic tubes by providing additional strength and stability. They act as a barrier between the soil and the tube, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile fabric also helps distribute the load evenly across the tube, preventing localized stress and potential failure. Additionally, geotextiles can improve filtration and drainage, allowing water to pass through while retaining the soil particles, thus enhancing the overall performance and longevity of the geosynthetic tube.

- Q: Basically I'm thinking of doing a thesis defense on this topic and I want to know if it is any good.

- Any bio-degradable material is not a better substitute for a geotextile material in long run Materials from polymer family may suit better, like Polyamide Polypropylene Polyethylene My answer refers to about having the ability to separate, filter, reinforce, protect, or drain If your purpose of using geotextile material regarding Beach Erosion, Riverbank Erosion, then coconut fibers is a better option

- Q: How are geotextiles recycled?

- Geotextiles can be recycled through a process called mechanical separation, where they are sorted, shredded, and then processed to remove any impurities. The shredded material is then transformed into new geotextile products or used as a raw material for other applications, reducing waste and promoting sustainability.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter fabric to prevent the migration of fine particles into the drainage system, while allowing water to flow through. By placing geotextiles behind the retaining wall, they help to enhance the drainage efficiency and overall stability of the system.

- Q: How do geotextiles contribute to the environmental sustainability of construction projects?

- Geotextiles contribute to the environmental sustainability of construction projects in various ways. Firstly, they help in soil stabilization by preventing erosion and promoting vegetation growth, thereby preserving the natural landscape and reducing the need for costly erosion control measures. Secondly, geotextiles can act as a filter, allowing water to pass through while trapping harmful pollutants, thus protecting surrounding water bodies from contamination. Additionally, they enhance the durability and lifespan of structures by providing reinforcement and reducing the need for excessive maintenance or repairs. Overall, geotextiles play a crucial role in minimizing the environmental impact of construction activities and promoting long-term sustainability.

- Q: How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by acting as a barrier between the soil and any applied loads or stresses. These textiles distribute the load more evenly, reducing the pressure on the soil and minimizing the potential for compaction. Additionally, geotextiles can improve soil stability and prevent erosion, further aiding in the control of soil compaction.

- Q: How are geotextiles used in sports field construction?

- Geotextiles are used in sports field construction to enhance the stability, drainage, and overall performance of the playing surface. They are typically installed as a layer between the subgrade and the topsoil, acting as a barrier to prevent the mixing of different soil layers while still allowing water to permeate through. This helps in preventing the formation of puddles and maintaining a consistent playing surface. Additionally, geotextiles can aid in soil stabilization, reducing the risk of erosion and promoting better turf growth.

Send your message to us

Geotextile Vt Non Woven with 100% Virgin Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords