Geotextile Nedir - Light Weight Biaxial Polypropylene Geogrid with Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

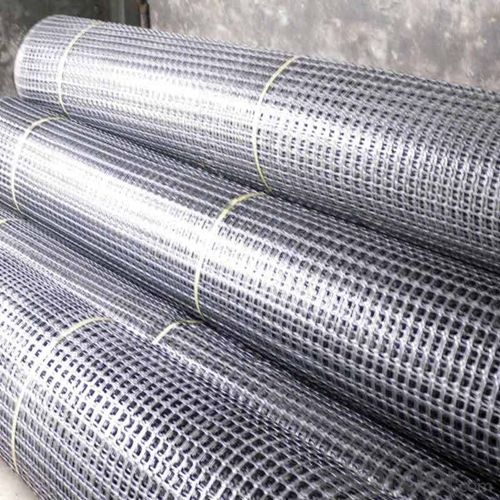

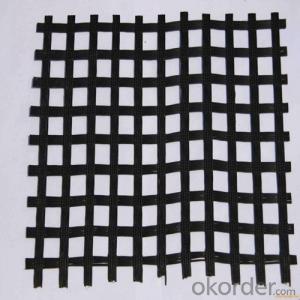

Biaxial Geogrids

Biaxial geogrids are designed to have roughly the same tensile strength in both directions and to distribute loads over a wider area, increasing the load capacity of the soil. Base reinforcing geogrids interlock with the aggregate to confine the base and reinforce the subgrade. In paved or unpaved applications, they reduce rutting and help maintain the desired aggregate depth.

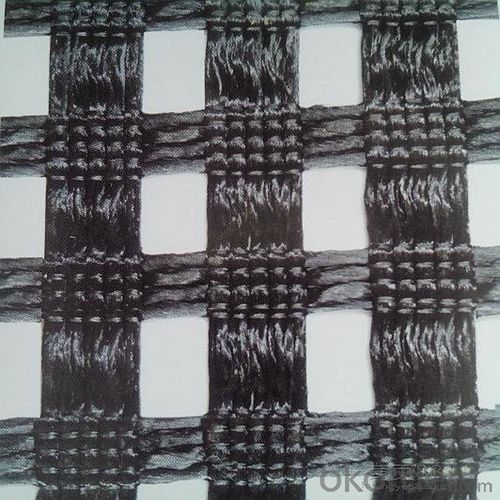

CNBM offers BaseGrid biaxial geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate. The two grids are offset before welding or stitching, creating a stable, continuous sheet with random-sized apertures for improved soil interaction.

Classify Fiberglass Geogrid Classify Polyester Geogrid

Material Fiberglass Material Polyester

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is geotextile cloth?

- Geogrid, geotextile, geomembrane manufacturers, specializing in the production

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement and stability to the soil used for lining the water bodies. They act as a barrier, preventing soil erosion and controlling the movement of fine particles, ensuring the integrity and longevity of the structure. Additionally, geotextiles promote proper drainage and filtration, enhancing water quality and preventing the accumulation of excess water within the pond or lake.

- Q: How do geotextiles help with erosion control in river channels?

- Geotextiles help with erosion control in river channels by providing a physical barrier that stabilizes the soil and prevents it from being washed away by flowing water. They also promote vegetation growth by allowing water to permeate while filtering out sediment, ultimately protecting the riverbanks from erosion.

- Q: What are the key considerations for geotextile installation in high temperature environments?

- The key considerations for geotextile installation in high temperature environments include selecting geotextiles that are resistant to thermal degradation, ensuring proper anchoring and securing of the geotextiles to prevent movement or displacement, and considering potential expansion and contraction of the geotextiles due to temperature fluctuations. Additionally, it is important to assess the long-term performance and durability of the geotextiles under high temperature conditions and to monitor their performance regularly to detect any signs of degradation or failure.

- Q: Are geotextiles suitable for use in gabion walls?

- Yes, geotextiles are suitable for use in gabion walls. Geotextiles help to improve the stability and durability of gabion walls by providing reinforcement and separation between the backfill materials and the stones within the gabion baskets. They also aid in preventing soil erosion, promoting proper drainage, and enhancing overall performance of the gabion structure.

- Q: Are geotextiles cost-effective?

- Yes, geotextiles are generally considered cost-effective due to their durability, longevity, and ability to prevent soil erosion and improve stability in various construction projects. They can reduce the need for expensive excavation or drainage systems, saving both time and money. Additionally, geotextiles can enhance the performance and lifespan of infrastructure, reducing maintenance and replacement costs in the long run.

- Q: How do geotextiles help with soil separation?

- Geotextiles help with soil separation by creating a barrier between different soil layers. They prevent the mixing of different soil types, which can lead to soil erosion and instability. Geotextiles also enhance drainage and filtration, allowing water to pass through while retaining soil particles, further aiding in soil separation.

- Q: Geotextile geomembrane factory need to record, certificate, inspection report?

- 0534- His highest answer the best

- Q: Can geotextiles be used for reinforcement of pipeline trenches?

- Yes, geotextiles can be used for reinforcement of pipeline trenches. Geotextiles are commonly used in civil engineering projects to enhance the stability and strength of soil. In the case of pipeline trenches, geotextiles can be placed as a separation layer between the soil and the pipeline, preventing soil intrusion and providing additional support to the pipeline structure.

- Q: Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

Send your message to us

Geotextile Nedir - Light Weight Biaxial Polypropylene Geogrid with Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords