Geotextile 2m HDPE Geotextile Membrane Liner for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

Thickness

1mm-3.0mm

width

4-9m

Length

50-100m or as customers' requests

Material

LDPE, LLDPE, HDPE, EVA, ECB, PVC , CPE

Color

Black, white, green, blue, red, grey, and others

Port

Qingdao

Delivery

2-20 days

Packing

woven bag or as customers' requests

Technical specifications of HDPE geomembrane:

a) Density ≥ 0.94g/m2

b) Tensile Strength ≥25Mpa

c) Elongation at Break ≥ 550%

d) Right-angled Tear ≥ 110N/mm

e.)Puncture Strength ≥ 550N

f.) Permeability Coefficient ≤1.0xe-13g.cm/(cm2.S.Pa)

g.) -70oC Low Temperature Impact Brittle Property: good.

h.) Chemical Resistance: at 80oC, marinated in 5g/L Nacl for a long time, it will not erode or swell.

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different factors that affect the performance of geotextiles?

- There are several factors that can affect the performance of geotextiles. These include the type and quality of the materials used, the design and construction of the geotextile, the installation and maintenance practices, the environmental conditions such as temperature and moisture, and the load and stress applied to the geotextile. Additionally, factors such as chemical exposure, biological activity, and aging can also impact the performance of geotextiles.

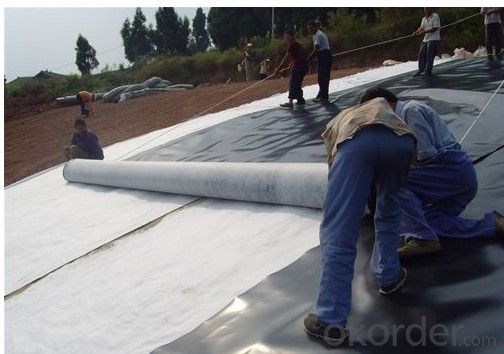

- Q: What are the different geotextile installation equipment and tools?

- Some different geotextile installation equipment and tools include: 1. Excavators: Used to prepare the ground by digging trenches or removing existing soil. 2. Trenchers: Specifically designed to create narrow trenches for laying geotextile materials. 3. Rollers: Used to compact the soil and ensure proper adhesion of the geotextile fabric. 4. Spreaders: Designed to evenly distribute the geotextile material over the prepared surface. 5. Staple guns: Used to secure the geotextile fabric to the ground or other surfaces. 6. Tensioners: Used to stretch and tighten the geotextile fabric during installation. 7. Cutting tools: Such as utility knives or scissors, employed to trim the geotextile material to the required size. 8. Anchor pins: Used to secure the geotextile fabric in place and prevent shifting. These tools and equipment aid in efficient and effective installation of geotextile materials, ensuring their proper functionality and longevity.

- Q: What are the challenges associated with geotextile installation?

- Some challenges associated with geotextile installation include: 1. Site preparation: Properly preparing the site before installing geotextiles can be challenging. It requires clearing the area of any debris, grading the surface, and ensuring a stable foundation. 2. Handling and transportation: Geotextiles can be bulky and heavy, making their handling and transportation challenging. Special equipment or manpower may be required to move and position them correctly. 3. Installation accuracy: Achieving precise alignment and placement of geotextiles is crucial for their effectiveness. It can be challenging to ensure proper positioning, especially in complex or irregular terrain. 4. Seaming and joining: Geotextiles often need to be seamed or joined together to cover larger areas. Achieving strong and reliable seams can be challenging, as it requires proper techniques and materials to ensure the integrity of the installation. 5. Durability and longevity: Geotextiles need to withstand environmental factors such as UV exposure, temperature variations, and chemical exposure. Ensuring their durability and longevity can be a challenge, as these factors can degrade the material over time. 6. Quality control: Proper quality control measures are necessary to ensure the geotextile installation meets the required standards. This includes performing regular inspections, testing, and adherence to specifications, which can be challenging to implement and maintain consistently. Overall, geotextile installation requires careful planning, skilled labor, and adherence to industry standards to overcome these challenges and achieve a successful installation.

- Q: Polyester non-woven and geotextile is not the same, what is the difference?

- In simple terms, the number of raw materials is different.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are designed to provide strength, stability, and filtration in various applications, including landfill construction. They can be used as a reinforcement layer in landfill liners or caps to enhance the stability and prevent erosion of the waste containment system.

- Q: How do geotextiles prevent soil erosion on slopes?

- Geotextiles prevent soil erosion on slopes by providing a stable and protective layer that helps retain the soil in place. These synthetic materials are placed on the slope and act as a barrier, preventing the soil from being washed away by rainfall or runoff. Geotextiles also promote proper drainage, allowing excess water to flow through while retaining the soil particles. This helps to maintain the integrity of the slope and reduce erosion caused by water movement.

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include understanding the slope stability and soil characteristics, selecting the appropriate type and strength of geotextile, ensuring proper anchoring and connection methods, implementing effective drainage systems, and regularly monitoring and maintaining the geotextile system.

- Q: How do geotextiles aid in the reduction of frost heave?

- Geotextiles aid in the reduction of frost heave by providing a barrier between the soil and the freezing temperatures, which helps to prevent the migration of water and the subsequent expansion of ice within the soil. This helps to minimize the upward pressure that causes frost heave, ultimately reducing the potential damage to structures or infrastructure.

- Q: Are geotextiles commonly used in riverbank protection applications?

- Yes, geotextiles are commonly used in riverbank protection applications. They are often employed to stabilize soil, prevent erosion, and enhance water filtration in riverbank protection projects.

- Q: You produce 700 grams of high-strength polypropylene geotextile it?

- 700 grams of high-strength polypropylene geotextile is designed for high-speed rail sliding layer of high-strength wear-resistant geotextile, our products in the West high-speed rail passenger line, OKorder and Hangzhou and other high-speed rail lines have applications.

Send your message to us

Geotextile 2m HDPE Geotextile Membrane Liner for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords