Geotextil Y Geomembrana Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Non Woven Description:

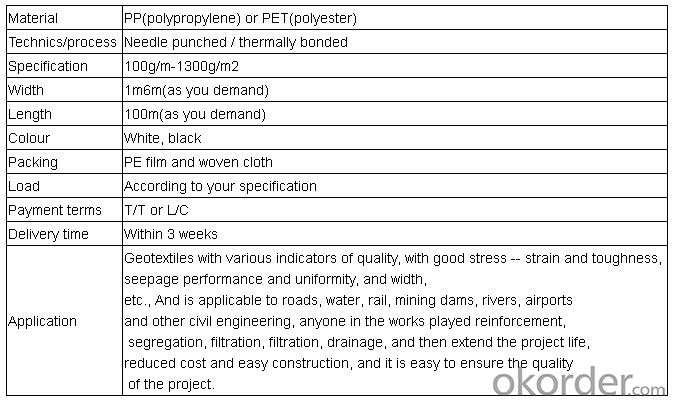

Specifications of PP Non Woven Geotextile for Road Construction:

1, Biggest Width: 6meter

2, Weight: about 90 gram to 800 gram

3, Treatment: UV protect

Application PP Non Woven Geotextile for Road Construction:

A: Subsurface drainage

B: Roadway separation

C: Hard armor underlayment

D:Asphalt overlay applications

Specification PP Non Woven Geotextile for Road Construction:

Functions and Features for PP Non Woven Geotextile for Road Construction:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Can geotextiles be used in stormwater detention systems?

- Yes, geotextiles can be used in stormwater detention systems. Geotextiles are commonly used in these systems to separate the soil and aggregate layers, to provide filtration and drainage, and to enhance the overall stability and performance of the system.

- Q: Geotextile detection sampling, how many meters

- General a square meter can be, I professional production

- Q: Under what circumstances drainage pipes need additional geotextiles

- Infiltration of water under the circumstances, geotextile play a filtering effect, Huazhi geotextile material manufacturers

- Q: What are the benefits of using geotextiles?

- There are several benefits of using geotextiles in various applications. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from being washed away by water or wind. Secondly, they enhance the drainage system by allowing water to pass through while retaining the soil particles, thus improving the overall performance of the infrastructure. Thirdly, geotextiles act as a barrier to separate different soil layers or materials, preventing their mixing and maintaining their integrity. Additionally, geotextiles can increase the load-bearing capacity of soils, making them suitable for construction or reinforcement purposes. Lastly, geotextiles are cost-effective and easy to install, reducing both the time and labor required for the project.

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. Geotextiles are commonly used to reinforce and stabilize soil by providing strength, preventing erosion, and promoting drainage. They are often used in various civil engineering applications such as road construction, embankments, and retaining walls to improve the stability and longevity of the soil.

- Q: Polyester geotextile price how much

- Is there a scientific name? Added: Will not it be filament geotext? This is what we have, but the scientific name does not call you this!

- Q: What are the materials used for spinning geotextiles?

- Spinning is made of synthetic fibers through acupuncture or weaving made of permeable geosynthetics. There are at least two sets of parallel yarns (or flat yarn), a group of looms along the loom (the direction of fabric travel) called warp yarns, another group The horizontal arrangement is called weft yarn.With the different weaving equipment and the process, the warp and the weft are woven together into a cloth, and can be knitted into different thickness and density according to different use range. Generally, the spinning and weaving cloth is thin and vertical Have a very strong tensile strength (longitude than latitude), with good stability. There are spinning geotextile according to the weaving process and the use of latitude and longitude is divided into reinforced geotextile and non-reinforced geotextile two categories, plus The tensile strength of the geotextile is much larger than that of the ordinary geotextile, and the general application of the geotextile is reinforced with the reinforcement of the geotextile project. The main function is reinforced by reinforcement and has the function of plane isolation and protection. Can be selected according to the specific purpose of use.

- Q: What are the applications of geotextiles in road construction?

- Geotextiles have several applications in road construction, including separation, filtration, reinforcement, and drainage. They are used to separate the subgrade soil from the aggregate base, preventing mixing and maintaining the structural integrity of the road. Geotextiles also act as a filtration layer, allowing water to pass through while preventing the migration of fine particles that can clog the drainage system. Additionally, they provide reinforcement to the road by distributing loads and reducing the potential for rutting and cracking. Lastly, geotextiles can be used for drainage purposes, helping to remove excess water from the road surface and subgrade, improving the durability and performance of the road.

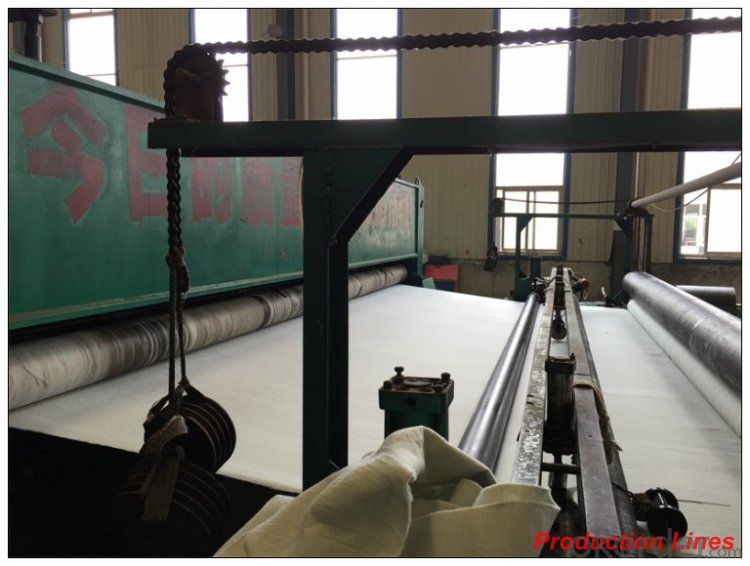

- Q: Manufacture of geotextile machinery

- Non-woven needle machine, I am specializing in the production of geotextiles

- Q: Waterproof geotextile in which the location of the culvert, what use

- Used in the top and side, lining the inside, mainly the role of waterproof to prevent water seepage. Huazhi geotechnical materials manufacturers need to answer for your needs

Send your message to us

Geotextil Y Geomembrana Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords