Geotextil Rollo HDPE High Strength Geocell for Parking Pot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

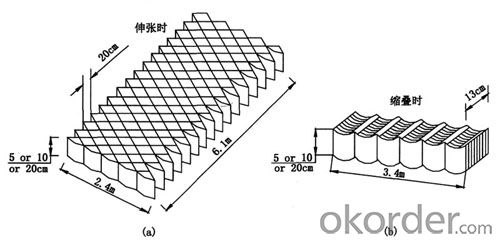

Description Of HDPE High Strength Geocell:

Geocells are engineered for protection and stabilization applications. They are often used to help improve the performance of standard construction materials and erosion-control treatments.

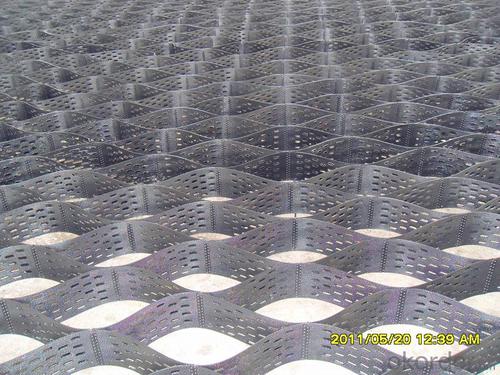

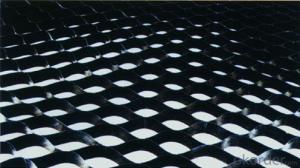

Geocell products are three-dimensional, expandable panels made from high-density polyethylene (HDPE), polyester or another polymer material.

Main Features of HDPE High Strength Geocell:

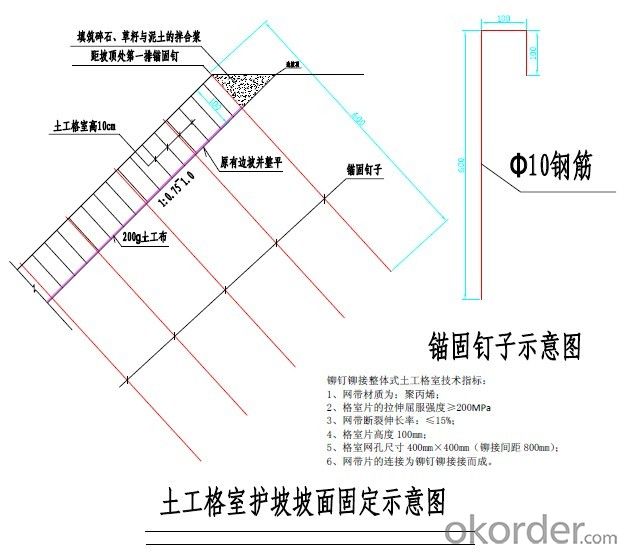

1. A deal and a half to fill half roadbed

In Acts on a natural slope of the ground: the time when the construction of the embankment slope 5, embankments should be dug basement stairs, step width of not less than 1M, phased construction or alteration road widening, the convergence of the old and the new embankment fill slope should be open dig stairs, stairs highway width is generally 2M, at each step horizontal surface laying Geocell, Geocell own use facade unconfined reinforced effect, a better solution to the problem of uneven subsidence.

2, sand subgrade

Sand subgrade should be dominated by a low embankment, filling height is generally not to be less than 0.3M. Due to sand roadbed subgrade construction and professional requirements of low weight bearing, using Geocell can play loose filler unconfined role in limited the high level of protection embankment has a high stiffness and strength to withstand the load stress of large vehicles.

3, reinforced embankment abutment

Using Geocell can better achieve the purpose of abutment back stiffened, and filler between Geocell can generate enough friction, reduce uneven settlement between the roadbed and structures, and ultimately to effectively alleviate the "jump abutment car "diseases of early deck of impact damage.

Specifications of HDPE High Strength Geocell:

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Seam Peel Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(N/Mpa) |

Flat and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.1/1.2 | ≥100 | ≥120 | ≥20 |

Flat and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.1/1.2 | ≥100 | ≥120 | ≥20 |

Embossed and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5 | ≥100 | ≥120 | ≥20 |

Embossed and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5 | ≥100 | ≥120 | ≥20 |

Remarks: Width of the product can be made according to the customer’s demand, and the other special standards will be carried out by agreement or contact | ||||||

Applications of HDPE High Strength Geocell:

1To stable the roadbed of highway/railway.

2.To bear the load of dyke, retaining wall.

3.To improve the watercourse of shallow river.

4.To support the pipeline and sewer.

5.To be used as independent wall, wharf and breakwater, etc..

6.To be used for the regulation of the desert, beaches, river bed and river bank.

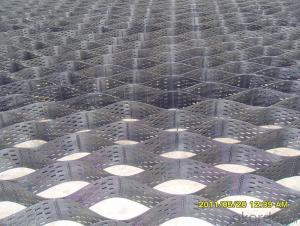

IMages of HDPE High Strength Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Is the case, we detect the company now want to engage in expansion (that is, increase the test items), the need for material to do qualification certification. But I have not done before, do not know their own data done unreasonable. Take the data mainly for reference, know the approximate range of the various parameters. Question added: it is best to have data logging source and derivation formula to support the reasonableness of this result, thank you! More

- Hello, can only help you this, do not know useful to you useless factory production geotextile geomembrane drainage board

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing additional reinforcement and stability. They act as a filtration layer, preventing soil erosion and allowing water to pass through while retaining fine particles. Geotextiles also enhance the strength and durability of geotubes by distributing loads evenly and reducing the risk of punctures or tears.

- Q: Can geotextiles be used in slope stabilization projects?

- Yes, geotextiles can be used in slope stabilization projects. Geotextiles are commonly used in slope stabilization to reinforce the soil and prevent erosion. They provide strength, stability, and filtration to the slope, reducing the risk of landslides and improving overall slope stability.

- Q: What are the advantages of using geotextiles in road construction?

- There are several advantages of using geotextiles in road construction. Firstly, geotextiles act as a barrier between the subgrade and the base material, preventing the mixing of the two layers. This helps in maintaining the stability and quality of the road. Secondly, geotextiles help in distributing the load more evenly across the road surface, reducing the stress on the underlying layers and increasing the lifespan of the road. Additionally, geotextiles can improve the drainage system by allowing water to flow through them, preventing the accumulation of water and reducing the chances of road damage due to moisture. Lastly, geotextiles are cost-effective and easy to install, saving both time and money in road construction projects. Overall, the use of geotextiles in road construction enhances the durability, strength, and performance of the road, making it a beneficial choice for infrastructure development.

- Q: Can geotextiles be used in erosion control on riverbanks?

- Yes, geotextiles can be used in erosion control on riverbanks. Geotextiles are often used as a stabilization measure to prevent soil erosion by providing a barrier against water flow and supporting vegetation growth. They help to retain soil while allowing water to pass through, reducing the impact of flowing water on riverbanks and preventing further erosion.

- Q: Is the polyester nonwoven fabric geotextile?

- Not geotextile. Polyester non-woven fabrics: mainly used for construction, roof waterproof as a base cloth, attached to the above sand, cement, etc., to prevent the role of sand leakage. Nonwovens are often used in construction and are a measure to prevent cracks. Geotextile manufacturers, for your answer

- Q: How do geotextiles affect soil settlement?

- Geotextiles can significantly affect soil settlement by providing reinforcement and stabilization to the soil. They distribute the load more evenly, reducing the settlement and potential for soil erosion.

- Q: Are geotextiles suitable for high-traffic areas?

- Yes, geotextiles are suitable for high-traffic areas. They are designed to provide stability, reinforcement, and filtration in soil and can effectively distribute loads. Geotextiles can help enhance the durability and longevity of high-traffic areas such as roads, parking lots, and walkways.

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can have both positive and negative effects on soil nutrient availability. On one hand, geotextiles can help retain nutrients in the soil by preventing their leaching and runoff, thus promoting their availability for plant uptake. On the other hand, if geotextiles are impermeable to water and air, they can hinder nutrient exchange processes and microbial activity, ultimately reducing nutrient availability in the soil. Therefore, the impact of geotextiles on soil nutrient availability depends on their design and application.

- Q: What are the advantages of using geotextiles in wetland restoration projects?

- There are several advantages of using geotextiles in wetland restoration projects. Firstly, geotextiles provide effective erosion control by stabilizing the soil and preventing it from washing away during heavy rainfall or flooding. This helps in maintaining the wetland's structure and preventing further degradation. Secondly, geotextiles act as a barrier, preventing the migration of harmful substances such as pollutants or excess nutrients from adjacent areas into the wetland, thus protecting its ecological integrity. Additionally, geotextiles can enhance vegetation growth by retaining moisture in the soil, promoting root development, and preventing weed growth. This ultimately contributes to the overall success of wetland restoration efforts.

Send your message to us

Geotextil Rollo HDPE High Strength Geocell for Parking Pot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords