Geomembrane Pool Polyethylene Waterproof Membrane with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane

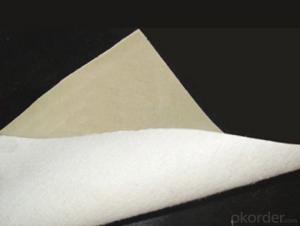

Composite Geomembrane with impermeable plastic film as a substrate, and non-woven geotextile composite made of impermeable material, which depends on the seepage properties of a impermeable plastic film performance

Features:

1.It can effectively make the concentrated stress diffuse, transfer or decompound, and prevent the soil mass against the destruction of outside force.

2.It can prevent the mixture of sandstone, soil mass and concrete of upper and lower layers.

3.Its mesh is hard to jam by virtue of the compliancy and motility of the reticulation formed by indefinite form fibrous tissue.

4.High water permeability-it can keep good water permeability even in the pressure of soil and water.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How to remove the mobile phone film?

- the film on the mobile phone can be directly removed, the above glue can be cleared: 1, the first step is using drawing eraser to wipe screen so you can remove most of the offset print; 2, the second step is to use a small amount of toothpaste, it is better to choose a good one, which is the kind will not wear CD box as advertised, a little bit evenly on the surface of the screen, but it is better not to seep into the screen edge seam. Then add a little water to slowly rub on the screen, you can remove stubborn dirt. 3,Second step, you can also use the wet paper towel gently wipe the residual dirt. 4, the third step, use a damp cloth to wipe clean the screen, a light screen appears.

- Q: How do geomembranes contribute to gas collection systems?

- Geomembranes contribute to gas collection systems by providing an impermeable barrier that prevents the escape of gases from landfills or other waste containment areas. These membranes effectively contain and direct the gases towards collection points, allowing for their efficient extraction and utilization as a source of renewable energy.

- Q: What are the advantages and disadvantages of ceramic and metal film membrane?

- Ceramic membrane material is acid and akali resistance, anti chemical solvents, high temperatures resistant, especially with high mechanical strength, long service life. it has obvious advantages in harsh environments. The disadvantage is that the application of ceramic membrane is not wide enough, although it is nanoscale separation precision. ceramic membrane has a small market, but there is no ceramic membrane that can not filter.

- Q: How do geomembranes contribute to the prevention of soil erosion in construction sites?

- Geomembranes contribute to the prevention of soil erosion in construction sites by acting as a barrier between the soil and external factors such as water, wind, and chemicals. They provide a stable and impermeable layer that prevents water from infiltrating the soil, reducing the potential for erosion. Additionally, geomembranes help to control the flow of water, directing it away from vulnerable areas and preventing the formation of rills and gullies. Overall, geomembranes play a crucial role in maintaining the integrity of the soil and protecting construction sites from erosion.

- Q: How to use the mobile phone laminator?

- The mobile phone is fixed on the mobile phone slot, and then switch the torque on the back to lift the height to the mobile phone screen. The method of application of mobile phone laminator read 2 take out the fixed SMD, one side is attached on the mebrane number 2, the mebrane is aligned at the back of screen mobile phone, and then the other side of the fixed SMD is pasted on the lifting platform. The operation method 3 of mobile phone laminator open the mebrane and clean the mobile phone screen, uncover the number 1 label of the mebrane, and press slowly the mebrane by the roller. Method 4 of using mobile phone laminator tear off the number 2 film, wipe the screen of the mobile phone with a clean cloth, which can squeeze out the rest of the bubble. Sticking the film is finished. The notice of the method of using mobile phone laminator It must clean the screen mobile phone before sticking the film.

- Q: High density polyethylene root-resistant geomembrane

- High density polyvinyl chloride root puncture resistant geomembrane, aslo called high density PVC root resistant membrane, is a kind of geomembrane which has good seepage-proof effect and good resistance to puncture as well. High density PVC root resistant membrane, with good flexibility and puncture resistance, can be used in a variety of complex construction environment. The width of common High density PVC root resistant membrane in current market is 2m. You can use dedicated welding machine when paving a large area of high density PVC root resistant membrane. Besides, the high density polyethylene root puncture resistant geomembrane in market is also called HDPE root resistant membrane which has better anti-seepage effect, anti-puncture ability and longer service life than High density polyvinyl chloride root puncture resistant geomembrane. It is also cheaper than High density polyvinyl chloride root puncture resistant geomembrane so it can completely replace High density polyvinyl chloride root puncture resistant geomembrane. The width of high density polyethylene root acupuncture resistant geomembrane in current market is 8m, which the common width is 6m. Compared with High density polyvinyl chloride root puncture resistant geomembrane, it can reduce welding cost in construction greatly.

- Q: What if there is water during construction of geomembrane?

- The main role of geomembrane on the road is water insulation, the part higher than the underground water level is isolated by geomembrane, and then backfill and grind, preventing the water through soil capillarity from soaking roadbed filler.

- Q: How to remove the heating film in the fish tank?

- The heating rod should sink into the water completely with the part contains heating wire downward, otherwise the heating rod will be burned. Wires do not need to be put into the water. When it is ensured that the heating rod is completely sunk in water, it is better to put as less electric wires in the water as possible. After all, the electric wire that is wrapped by plastic will age faster when soaked in water.

- Q: What are the considerations for geomembrane installations in areas with high groundwater salinity?

- When installing geomembranes in areas with high groundwater salinity, several considerations need to be taken into account. Firstly, the chosen geomembrane material should be resistant to the corrosive effects of saline water to ensure its long-term durability. Additionally, proper site preparation is crucial to minimize potential damage to the geomembrane during installation. It is essential to assess the groundwater salinity levels and their potential impact on the geomembrane's performance and integrity. Adequate pre-installation testing and monitoring are necessary to determine the appropriate thickness and design of the geomembrane to withstand the high salinity conditions. Finally, regular inspection and maintenance should be conducted to identify any signs of deterioration or damage and take timely corrective measures to ensure the effectiveness of the geomembrane in areas with high groundwater salinity.

- Q: Which is better for geomembrane hot melting in the middle of sliding layer of high-speed railway bridge two cloth and one membrane, lapping or docking? And what is the lapping length if it is lapping hot melting?

- In general, it should not be cut according to graphic size. Shorten joint length and strain as far as possible. After geomembrane pavement, the lap?width between films should be not less than 10 cm. 4. Usually set at a corner and abnormal section. 6, arrange along the gradient direction and avoid accidental damage to membrane when the temperature is low. Lap width between membranes is generally not less than 10 cm. You should measure the accurate relative size. Do not weld as far as possible during geomembrane pavement . In addition to the special requirements, Do not walk on the membrane or carry on the membrane.

Send your message to us

Geomembrane Pool Polyethylene Waterproof Membrane with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords