Geomembrana Medidas Waterproof Membrane Roll 2024 New Design

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

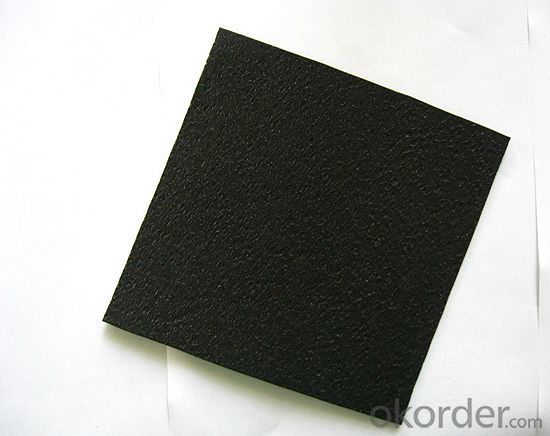

HDPE Geomembrane

Thickness: 1.0mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LDPE Geomembrane

Thickness: 0.1mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

1. high quality hdpe geomembrane use in agriculture farm

3. high quality hdpe geomembrane use in shrimp ponds orLotus

4. high quality hdpe geomembrane use in Slope protection impervious

5. high quality hdpe geomembrane use in Landfill anti-seepage

Hydraulic Engineering: Canal waterproof, Dam leaking stoppage, reinforcement, Vertical core, Slope protection, Revetment, etc.

Municipal Engineering: Tunnel, Subway, Planted roof, Roof garden,Sewage conduit lining, etc.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the considerations for geomembrane installations in areas with high seismic activity?

- When installing geomembranes in areas with high seismic activity, several considerations should be taken into account. Firstly, it is essential to choose a geomembrane material with high tensile strength and flexibility to withstand the ground movements caused by earthquakes. Additionally, the geomembrane should have excellent puncture resistance and tear strength to prevent any damage during seismic events. Another important consideration is the anchoring system. Geomembranes should be adequately anchored to prevent excessive movement or uplift during seismic activity. This may involve using anchor trenches, batten bar systems, or other securing methods that can withstand the forces generated by earthquakes. Furthermore, proper site characterization and geotechnical investigations are crucial in understanding the soil conditions and potential liquefaction risks in the area. This information helps in designing appropriate foundation systems and selecting the most suitable geomembrane installation techniques. Overall, the considerations for geomembrane installations in areas with high seismic activity include choosing the right material, ensuring proper anchoring, and conducting thorough site investigations to mitigate potential risks associated with earthquakes.

- Q: What are the advantages of using geomembranes in coastal and marine protection projects?

- Geomembranes offer several advantages in coastal and marine protection projects. Firstly, they act as a barrier, preventing water infiltration and reducing the risk of erosion. This helps to stabilize the coastline and protect valuable infrastructure from being damaged by waves and currents. Additionally, geomembranes are highly durable and resistant to UV degradation, ensuring long-term performance and reducing the need for frequent maintenance. Furthermore, these materials are flexible and can be customized to fit various shapes and sizes, making them suitable for different project requirements. Lastly, geomembranes have low permeability, which prevents contaminants from seeping into the water, safeguarding the marine ecosystem and preserving water quality. Overall, the use of geomembranes in coastal and marine protection projects improves resilience, reduces environmental impact, and enhances the overall effectiveness of these initiatives.

- Q: Are geomembranes resistant to UV degradation in different climates?

- Yes, geomembranes are generally resistant to UV degradation in different climates. However, the degree of resistance may vary depending on the specific type of geomembrane material used and the duration and intensity of UV exposure. It is important to consider the specific climate conditions and consult with experts to choose the most suitable geomembrane for each application.

- Q: What are the advantages of using geomembranes in aquaculture facilities?

- There are several advantages of using geomembranes in aquaculture facilities. Firstly, geomembranes provide a protective barrier against seepage and leakage, preventing the loss of water and valuable resources. Secondly, they help maintain optimal water quality by preventing the intrusion of contaminants and pollutants. Additionally, geomembranes offer a flexible and durable solution, allowing for easy installation and customization to different facility designs. This can help reduce construction costs and increase operational efficiency. Lastly, geomembranes minimize the risk of disease transmission and improve biosecurity, ensuring a healthier and more sustainable environment for aquaculture operations.

- Q: What are the potential risks associated with geomembranes?

- Some potential risks associated with geomembranes include punctures or tears, improper installation leading to leaks, degradation over time due to environmental factors, and potential for contamination if not properly maintained. Additionally, geomembranes may pose a risk to human health if toxic materials are used in their production or if they are not properly disposed of at the end of their lifespan.

- Q: How are geomembranes tested for quality?

- Geomembranes are tested for quality through various methods such as visual inspection, destructive and non-destructive testing, and laboratory analysis. Visual inspection involves inspecting the geomembrane for any visible defects or irregularities. Destructive testing may involve puncturing or tearing a sample of the geomembrane to evaluate its strength and durability. Non-destructive testing methods include measuring thickness, conducting leak detection tests, and assessing the geomembrane's resistance to chemicals and environmental factors. Laboratory analysis involves subjecting samples to various tests to assess their physical, mechanical, and chemical properties, ensuring that they meet the required standards and specifications. Overall, a combination of these testing methods is employed to ensure the quality and performance of geomembranes.

- Q: How many square meters of geomembrane is a group?

- 10,000 square meters

- Q: Does any one know about that what kinds of PVC film can be used to make cabinet?

- As for PVC film, usually the imported type 35 to type 65 are more thick, domestic film is thin.

- Q: What are the requirements for geomembranes used in wastewater treatment plants?

- The requirements for geomembranes used in wastewater treatment plants include being chemically resistant to various contaminants and corrosive substances found in wastewater, having high tensile strength and puncture resistance to withstand potential stress and impacts, demonstrating durability and long-term performance in harsh environmental conditions, and being impermeable to prevent leakage and seepage of wastewater. Additionally, the geomembrane should be compatible with the installation methods and equipment used in wastewater treatment plants and meet regulatory standards for water quality and environmental protection.

- Q: Where has good geomembrane tensile machine?

- The gate-type structure of main engine of mechanical tensile machine is mainly suitable for rubber, plastics, textiles, geotextiles, waterproofing materials, wire and cable, net twine, metal wire, metal bar, metal plates and other materials tensile test increasing appendage to do bend, tear, peel and other tests detecting instruments

Send your message to us

Geomembrana Medidas Waterproof Membrane Roll 2024 New Design

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords