Pe Geomembrane 0.5 mm HDPE for Dam - Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrana 0.5 mm of HDPE for The Dam Made in China

Description Of Geomembrana 0.5 mm of HDPE for The Dam Made in China

Geomembrane is a plastic Film Raincoat. Currently, the main raw materials of Waterproof Geomembrane are mainly Plastic polyvinyl chloride (PVC) and polyethylene (PE), Eva (ethylene / vinyl acetate Copolymer), also designed for Special use in applications of Tunnel (ECB Ethylene vinyl acetate Modified Asphalt mixture Geomembrane).

Main Features of Geomembrana 0.5 mm of HDPE for The Dam Made in China

Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane, linear low density polyethylene (LLDPE) geomembrane

Applications of Geomembrana 0.5 mm of HDPE for The Dam Made in China

1.HDPE geomembrane is applicable to hydraulic engineering: such as seepage control, plugging, reinforcement for rivers, lakes and reservoirs and dams, drainage seepage control, vertical core wall, slope protection, etc.

2. HDPE geomembrane's applications in municipal engineering: subway, underground works of the building, planting roof, roof garden, sewage pipe seepage control;

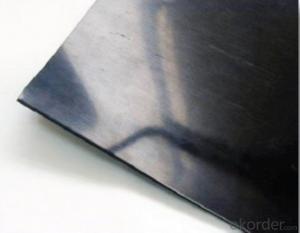

IMages of Geomembrana 0.5 mm of HDPE for The Dam Made in China

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: What is the role of geomembranes in desalination plants?

- The role of geomembranes in desalination plants is to act as a barrier to prevent the leakage or contamination of the treated water. These impermeable synthetic liners are used to line the reservoirs, basins, and storage ponds in desalination plants, ensuring that the purified water remains separate from the surrounding soil or groundwater. Geomembranes also help in managing the brine discharge, preventing its seepage into the environment and protecting the ecosystem.

- Q: Can geomembranes be used in decorative pond installations?

- Yes, geomembranes can be used in decorative pond installations. They are often used as a flexible and durable lining material to prevent water leakage and provide a smooth surface for pond features such as waterfalls, fountains, and rock formations.

- Q: Geomembrane classification

- Seen from the naked eye, particulate is because the feed back material is added too much. Secondly, take samples of the material on site and sent to relevant national authorities to be tested, while adding too much back material will cause the HDPE membrane not reaching American standard index, indicating that the material is not very good, but one thing you can see, as well as some granular things, sand holes on the membrane, which is difficult to distinguish

- Q: How do geomembranes contribute to erosion control in mining reclamation projects?

- Geomembranes contribute to erosion control in mining reclamation projects by acting as a barrier between the soil and water, preventing erosion and sedimentation. They effectively reduce water infiltration, control surface runoff, and protect underlying soil from erosion caused by wind and water. Additionally, geomembranes help in stabilizing slopes, preventing soil movement, and maintaining the integrity of the reclaimed area, thus promoting sustainable and successful mine reclamation efforts.

- Q: What's the stick membrane methods of waterproof mobile?

- the stick membrane methods of waterproof mobile phone: packaging equipment of mobile phone stick membrane: 1, damp cloth, fiber cloth, dedusting paster, phone protective film, scratch cards and changing the stick membrane labels, steps of phone's stick membrane, to clean the screen: 2, wipe the screen with damp cloth, rub back and forth for multiple times, try best to wipe the phone to clean, damp cloth will clean grease and fingerprints of the screen 3, wipe the screen with locomotive fiber cloth, do not worry about dust or wool stuck on the screen, following links can be handled 4, using locomotive dedusting paster to clean stubborn dirt, dust or wool can be affixed to cleanly, steps of mobile phone stick membrane, second step, screen stick membrane: put the phone protective film out of the packaging, directly place the phone protector on the screen and feel the bonding situation of stick membrane and screen, the position of stick membrane, 5, there are two labels on phone protective film, firstly, tear 1 label and stick the phone packaging film to the phone screen, 6, notice to align the hole and the edges of phone screen, and the hand should not be sticked to the phone screen. 7, after stick the packaging film to the screen, tear 2 label, 8, if there exists bubble, you can use locomotive scratch cards to scratch the bubble on the screen, eliminating the bubbles, 9,( if there are bubbles can't be scratched out, you can stick the stick membrane with cleaning paste, then scratch the bubbles with scratch cards) 10, wipe the screen with cloth, the whole stick membrane process will be finished.

- Q: Are geomembranes suitable for use in industrial waste management?

- Yes, geomembranes are suitable for use in industrial waste management. They offer an effective barrier to prevent the leakage or seepage of hazardous materials into the environment. Additionally, geomembranes are durable, flexible, and resistant to various chemicals, making them a reliable choice for containing and managing industrial waste.

- Q: How do geomembranes withstand environmental stressors?

- Geomembranes withstand environmental stressors through their inherent physical properties and design. These stressors include factors like temperature variations, chemical exposures, UV radiation, and mechanical forces. Geomembranes are typically made from durable materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM), which possess excellent resistance to these stressors. Additionally, geomembranes can be reinforced with additives or multiple layers to enhance their strength and resistance. Proper installation techniques, including anchoring, welding, or seaming, also contribute to their ability to withstand environmental stressors and maintain their integrity over time.

- Q: In what industry can seepage-proof geomembranes be applied?

- HDPE membranes are applicable to aquaculture?industry; 6:washing ponds, power plant regulating reservoirs. Polyethylene seepage-proof membranes are applicable to gardens. Intensification: such as the seepage-proof control of rivers and lakes, reservoirs and dams; HDPE geomembranes are applicable to environmental protection, such as waterproof and dampproof management of revetments, afforesting lawns,etc. 9. the seepage-proof control of heap leachings and bottom lining of tailings, impounding reservoirs, chemical plants, seepage proofing for irrigation systems, impounding ponds, and the seepage control and reinforcement of ditches. Polyethylene geomembranes with high density are applicable to petrochemical industry and vertical core walls. HDPE seepage-proof membranes are applicable to municipal?engineerings, sanitation, reservoirs, the bottom of golf course ponds, drinking water ponds. LDPE seepage-proof membranes are applicable to agricultural industry, the seepage-proof control of roof gardens and culverts, settling ponds and revetments, subways, dissolving?tanks, saltern crystallizing ponds. 2. leaking?stoppage: road reinforcement, such as refuse landfills, sea cucumber revetments, etc. 7;4. halogen pool caps, ashery. 5. refinery, sewage?disposal?plants, fishponds twice linings, building underground constructions, and lining of sedimentation tanks; 3.chemical reaction pools: artificial?lakes, hospital solid wastes, the seepage-proof control of oil tanks. high density polyethylene impermeable membranes are applicable to salt industry, lining of shrimp ponds. LDPE seepage-proof membranes are applicable to water?conservancy industry. Seepage-proof membranes application fields1, factory-like culture ponds, sewage conduits; 8. storage?yards, salt membranes. Polyethylene geomembranes are applicable to mining industry, planted roofs. Low density polyethylene membranes are applicable to transportation facilities, and plastic straw mat membrane in saltern;10

- Q: How do geomembranes provide water retention in rooftop gardens?

- Geomembranes provide water retention in rooftop gardens by acting as a barrier between the garden soil and the rooftop surface. They prevent water from seeping through the roof and provide a waterproof layer, ensuring that the water remains within the garden area. This allows for efficient water management, reduces water runoff, and keeps the plants adequately hydrated, promoting healthy growth in the rooftop garden.

- Q: What are the advantages of using geomembranes in hydroelectric power generation projects?

- There are several advantages of using geomembranes in hydroelectric power generation projects. Firstly, geomembranes provide an effective barrier system that helps prevent water seepage and leakage, ensuring the integrity and stability of the water storage reservoirs and canals. This reduces the risk of water loss and potential damage to surrounding ecosystems. Secondly, geomembranes offer excellent chemical resistance, making them suitable for use in hydroelectric projects where the water may contain corrosive elements. This enhances the durability and longevity of the infrastructure. Furthermore, geomembranes are highly flexible and adaptable, allowing for easy installation on various types of terrain, including uneven or sloped surfaces. This flexibility ensures that the geomembranes can conform to the terrain and provide a secure lining system. Another advantage is that geomembranes are impermeable to gases, preventing the escape of harmful gases such as methane, which can be produced during the decomposition of organic matter in water reservoirs. This helps in maintaining a safe and environmentally friendly operation. Lastly, geomembranes have low maintenance requirements and are resistant to UV radiation, weathering, and biological degradation. This reduces the need for frequent repairs or replacements, resulting in cost savings over the long term. Overall, the use of geomembranes in hydroelectric power generation projects provides enhanced water containment, improved environmental protection, and reduced maintenance, making them a beneficial choice for such projects.

Send your message to us

Pe Geomembrane 0.5 mm HDPE for Dam - Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords