Geomembrana 0.8 mm of HDPE for The Tank Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

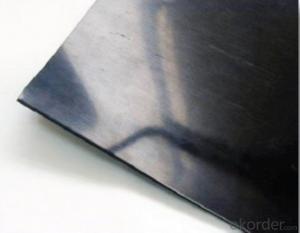

Geomembrana 0.8 mm of HDPE for The Tank Made in China

Description Of Geomembrana 0.8 mm of HDPE for The Tank Made in China

Geomembrane is a plastic Film Raincoat. Currently, the main raw materials of Waterproof Geomembrane are mainly Plastic polyvinyl chloride (PVC) and polyethylene (PE), Eva (ethylene / vinyl acetate Copolymer), also designed for Special use in applications of Tunnel (ECB Ethylene vinyl acetate Modified Asphalt mixture Geomembrane).

Main Features of Geomembrana 0.8 mm of HDPE for The Tank Made in China

Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane, linear low density polyethylene (LLDPE) geomembrane

Applications of Geomembrana 0.8 mm of HDPE for The Tank Made in China

1. Polyethylene geomembrane is applicable to mining: washing pool, soaking pool, the ash-field, dissolving pool, settling pool, yard, tailings substrates seepage control;

2. Low density polyethylene geomembrane for transport facilities: foundation reinforcement for the road, culvert seepage control

IMages of Geomembrana 0.5 mm of HDPE for The Dam Made in China

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can geomembranes be used in potable water applications?

- Yes, geomembranes can be used in potable water applications. They are often utilized as a barrier material in water containment systems to prevent leakage and contamination, ensuring the safety and quality of drinking water.

- Q: Are geomembranes suitable for use in geothermal energy projects?

- Yes, geomembranes are suitable for use in geothermal energy projects. Geomembranes are flexible and durable materials that can effectively contain and control fluids, making them ideal for lining geothermal well pads and reservoirs. They provide a barrier against fluid leakage, prevent soil contamination, and help maintain the integrity of the geothermal system. Additionally, geomembranes have excellent thermal properties, which can contribute to the overall efficiency and performance of geothermal energy projects.

- Q: Can geomembranes be used in gas barrier applications?

- Yes, geomembranes can be used in gas barrier applications. They are commonly used in various industries such as waste management, mining, and oil and gas, to contain and control the movement of gases. Geomembranes act as a barrier and prevent the migration of gases, ensuring safety and environmental protection.

- Q: How do geomembranes contribute to erosion control in pipeline and utility corridor construction?

- Geomembranes contribute to erosion control in pipeline and utility corridor construction by providing a protective barrier against soil erosion. They are placed on slopes or areas prone to erosion to prevent sediment runoff and the displacement of soil particles. This helps to maintain the stability of the construction site, reduce sedimentation in nearby water bodies, and minimize the environmental impact of the project.

- Q: What is the water proof method of electric heating film?

- If floor drain is blocked, and the house decoration has just been finished, you can find a decoration company, will not be blocked to the main pipe.

- Q: Do geomembranes require regular maintenance?

- Yes, geomembranes typically require regular maintenance to ensure their longevity and effectiveness. Regular inspections, cleaning, and repairs are necessary to address any potential damages or deterioration caused by environmental factors, installation issues, or aging. Timely maintenance helps to prevent leaks, tears, or other failures and ensures the geomembranes continue to function as intended.

- Q: imported geomembrane domestic raw materials .

- Now in the factory in accordance with GRI-GM13 standard we make the the goods using a new material geomembrane. after all, the price gap depends on the actual needs.

- Q: Should the protective?film of the refrigerator be torn off?

- It is best to tear it off when you use it. Protective film is used to protect the surface from scratching during transportation. It should be torn off after you buy the refrigerator. If not, it will affect the cooling of the refrigerator. Just touch the surface and you will find it warm.

- Q: Can geomembranes be customized for specific projects?

- Yes, geomembranes can be customized for specific projects. They can be tailored to meet specific requirements such as size, strength, durability, and chemical resistance. Customization allows geomembranes to be used effectively in various applications, including waste containment, water storage, mining, agriculture, and construction. This flexibility in customization ensures that geomembranes can be optimized for specific project needs.

- Q: Can geomembranes be used in pond lining?

- Yes, geomembranes can be used in pond lining.

Send your message to us

Geomembrana 0.8 mm of HDPE for The Tank Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords