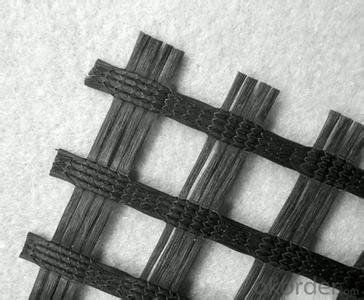

Geogrids Fort Mcmurray - PVC Coated Polyester Geogrid with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

Features:

1.Intensity of vertically and horizontally from 20 KN/M to 150 KN/M

2.Low breaking elongation, not bigger than 3%

3.Suitable for each kind of soil environment

4.For treatment on surface, the rib suppresses the rough pattern, strengthens the grill surface the rough degree, enhances the GSZ steel plastic complex geogrid in the soil body friction factor.

5.It has more superior breadth, up to 2- 6 m, reducing construction joining, enhances the work efficiency.

6.High intensity, low creep and distorting

7.Resistant to erosion, longer life.

8.Easy and convenient to install, short period and low cost- saving. It can save project cost by 10%- 50%.

FAQ:

Q: Can you accept small trial order?

A: Yes, we accept small trial orders at reasonable charge.

Q:May I get one sample for checking out the quality? How much?

A: Yes, we supply sample free of charge, and the freight will be on buyer’s account, which is refundable when order confirmed.

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: How do geogrids help in reducing construction labor requirements?

- Geogrids help in reducing construction labor requirements by providing stability and reinforcement to soil, allowing for the use of thinner layers of fill material. This reduces the need for extensive excavation and material placement, thus minimizing the amount of manual labor involved in the construction process.

- Q: What is the role of geogrid?

- Unidirectional geogrid reinforcement for River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period. The geogrid reinforcement material constitutive model

- Q: Bi directional plastic geogrid is suitable for engineering

- Slope protection, wall reinforcement, large airport, parking lot

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge piers?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge piers. Geogrids provide additional tensile strength and stability to the soil, improving the overall performance and load-bearing capacity of the bridge piers. They are commonly used in conjunction with other reinforcement materials to enhance the structural integrity and longevity of the bridge piers.

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth retaining walls on soft soils?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth retaining walls on soft soils. Geogrids are commonly used to enhance the stability and load-bearing capacity of retaining walls by providing tensile strength and reducing lateral movement of the soil. In soft soils, geogrids can help distribute the applied loads evenly and prevent excessive settlement or deformation of the retaining wall system.

- Q: Are geogrids resistant to biodegradation?

- Yes, geogrids are generally resistant to biodegradation. They are constructed using synthetic materials such as polyester or polypropylene, which have low susceptibility to biological degradation. This makes geogrids durable and suitable for long-term use in various applications, including soil stabilization and erosion control.

- Q: See details of the application of design code for railway embankment geosynthetics TB10018-2006

- See details of the application of design code for railway embankment geosynthetics TB10018-2006

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- Fill enough paint to make it smooth.6, removal of leakage of tape. Then, note that all of the cracks have been properly repaired, with a fine composite material will be modified around the repair, so that it is as bright as new.

- Q: Can geogrids be used in temporary construction haul roads for mining applications?

- Yes, geogrids can be used in temporary construction haul roads for mining applications. Geogrids are commonly used in such scenarios to reinforce the road base, improve stability, and prevent soil erosion. They provide increased load-bearing capacity, reduce rutting, and can withstand heavy vehicle traffic, making them an ideal solution for temporary haul roads in mining operations.

Send your message to us

Geogrids Fort Mcmurray - PVC Coated Polyester Geogrid with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords